Solid phase extraction and enrichment method of nitrogen-containing compounds in diesel fuel

A nitrogen compound and solid-phase extraction column technology, which is applied in the petroleum industry, refined hydrocarbon oil, instruments, etc., can solve the problems of separation crossover between components, large amount of solvent consumption, long time, etc., and achieve small separation crossover and solvent consumption Less, the effect of improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

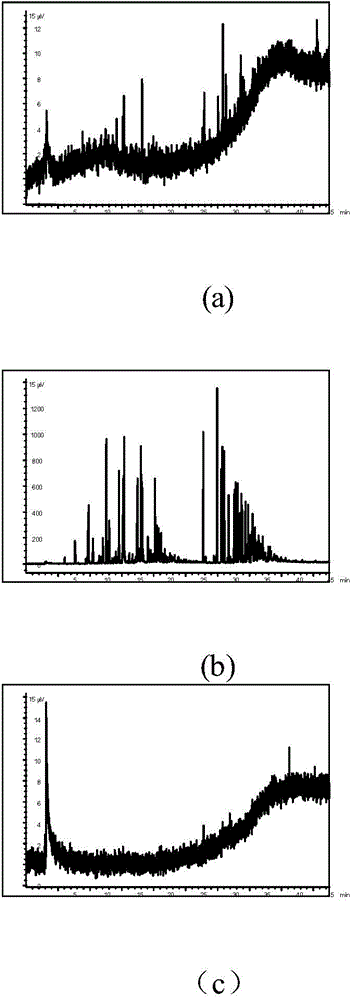

[0035] Pack 3.5g of silica gel-acidic alumina stationary phase with 10wt% acidic alumina content in the solid phase extraction column, wet with 2mL of the first eluent (the volume ratio of n-pentane to dichloromethane is 1:1) .

[0036] Use a pipette gun to take 2mL of Qingyang Petrochemical catalytic cracked diesel oil into the upper part of the solid phase extraction column and be completely absorbed by the stationary phase. Rinse the solid-phase extraction column with 8 mL of the first eluent to obtain saturated hydrocarbons and aromatic hydrocarbons, which are designated as component 1. Rinse the solid-phase extraction column with 10 mL of the second eluent (the volume ratio of dichloromethane and ethanol is 90:10) to obtain nitrogen-containing compounds, which are designated as component 2. Rinse the solid-phase extraction column with 10 mL of ethanol to obtain heavy components such as colloids, which are recorded as component 3. Solvents in saturated hydrocarbons, arom...

Embodiment 2

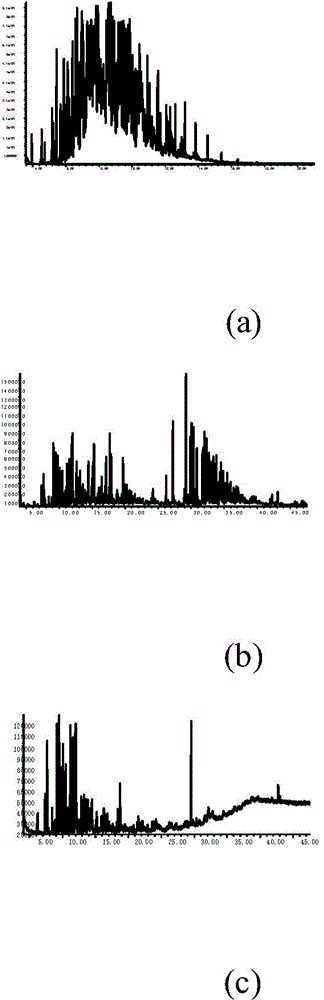

[0046] 4.0 g of silica gel-alumina stationary phase with an alumina content of 20 wt % was filled in the solid phase extraction column, and wetted with 2 mL of the first eluent.

[0047] Use a pipette gun to take 1.5mL Karamay Petrochemical catalytic cracked diesel oil into the upper part of the solid phase extraction column and be completely absorbed by the stationary phase. Rinse the solid-phase extraction column with 8 mL of the first eluent to obtain saturated hydrocarbons and aromatic hydrocarbons, which are designated as component 1. Rinse the solid-phase extraction column with 10 mL of the second eluent to obtain a nitrogen-containing compound, which is recorded as component 2. Rinse the solid-phase extraction column with 10 mL of ethanol to obtain heavy components such as colloids, which are recorded as component 3. Solvents in saturated hydrocarbons, aromatics and nitrogen-containing compounds were removed by rotary evaporator and nitrogen purge.

[0048] GC-NCD was...

Embodiment 3

[0056] 4.0 g of silica gel-alumina stationary phase with an alumina content of 40 wt % was filled in the solid phase extraction column, and wetted with 2 mL of the first eluent.

[0057] Use a pipette gun to take 2mL of Changqing Petrochemical catalytic cracked diesel oil into the upper part of the solid phase extraction column and be completely absorbed by the stationary phase. Rinse the solid-phase extraction column with 8 mL of the first eluent to obtain saturated hydrocarbons and aromatic hydrocarbons, which are designated as component 1. Rinse the solid-phase extraction column with 10 mL of the second eluent to obtain a nitrogen-containing compound, which is recorded as component 2. Solvents in saturated hydrocarbons, aromatics and nitrogen-containing compounds were removed by rotary evaporator and nitrogen purge. Enrichment of nitrogen-containing compounds in Qingyang Petrochemical Catalytic Cracking Diesel Oil can be completed in only 20 minutes by adopting the inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com