Processing method of prickly ash seed kernel oil

The technology of pepper seed kernel and processing method is applied in the direction of fat oil/fat production, fat oil/fat refining, fat generation, etc. It can solve the problems of high cost, complicated process, solvent residue, etc., and achieve low cost, strong operability, The effect of low solvent residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

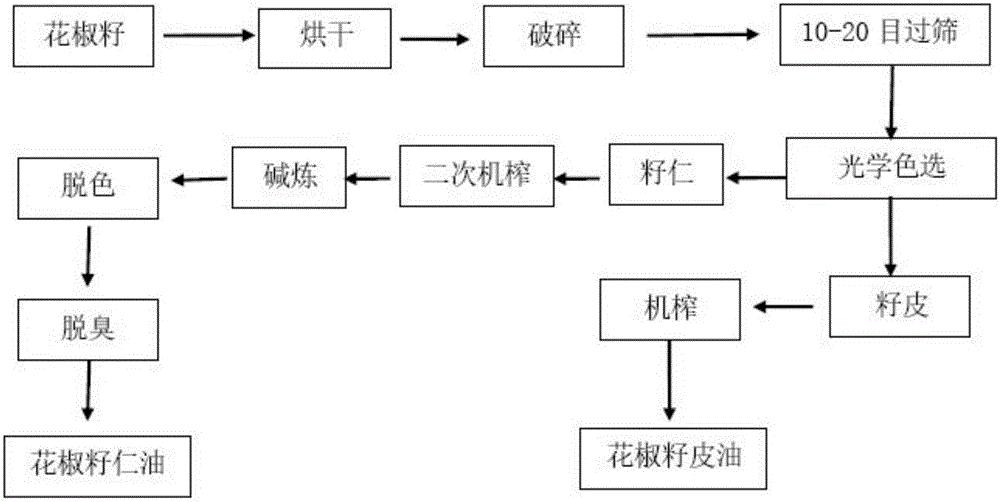

[0021] Such as figure 1 Shown, the processing method of the Zanthoxylum bungeanum seed oil in the embodiment, comprises the following steps:

[0022] Step 1: crush the dried pepper seeds into granular materials; use material sorting machinery to sort out the black seed shells and white kernels in the granular materials, squeeze the kernel particles and collect them to obtain the pepper kernel hairs Oil;

[0023] Step 2: Alkali refining process: Add a mixture of ethanol-sodium hydroxide aqueous solution that is 1-2 times the weight of crude oil to the crude oil, stir at 25-60°C for 1-3h, then stand still for 1-3h, and stratification occurs. Separate the upper oil phase;

[0024] Step 3: heating the oil phase to 40°C-60°C for dehydration, then decolorizing with diatomaceous earth, filtering, and deodorizing to obtain Zanthoxylum bungeanum seed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com