Asterias amurensis enzymatic hydrolysis polypeptide and application thereof as ACE inhibitor

A technology of enzymolysis and enzymatic hydrolysis of sea thorns, which is applied in the field of enzymatic hydrolysis of peptides of sea thorns, can solve problems such as side effects, and achieve the effects of low cost, easy acquisition, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

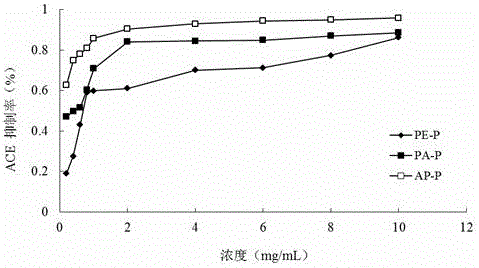

[0022] Put the whole thorny sea bark into a drying oven, dry and crush it at 65°C, pass through a 20-mesh sieve, mix the thorny sea bark powder with distilled water at a solid-to-liquid ratio of 1:20g / ml, And add pepsin to it, the added pepsin is 5% of the mass of sea thorn carcass, after stirring evenly, adjust the pH=2.0 with concentrated hydrochloric acid, and then enzymolyze it in a constant temperature water bath for 8 hours under the condition of 37°C , to obtain the enzymatic hydrolyzate of S. spinosae, put the enzymatic solution of S. spinacha in a boiling water bath for 10 minutes, and then centrifuge after cooling. Centrifugation conditions: 4000r / min, centrifuge for 15min, then take the supernatant, dialyze, concentrate, Freeze-dry to obtain pepsin-enzymatic polypeptide (PE-P).

Embodiment 2

[0024] Put the whole thorny sea bark into a drying oven, dry and crush it at 65°C, pass through a 20-mesh sieve, mix the thorny sea bark powder with distilled water at a solid-to-liquid ratio of 1:20g / ml, And add papain to it, the added papain is 5% of the mass of spiny caravan, after stirring evenly, adjust the pH=6.5 with concentrated hydrochloric acid, and then enzymolyze it in a constant temperature water bath for 8 hours under the condition of 60°C , to obtain the enzymatic hydrolyzate of S. spinosae, put the enzymatic solution of S. spinacha in a boiling water bath for 10 minutes, and then centrifuge after cooling. Centrifugation conditions: 4000r / min, centrifuge for 15min, then take the supernatant, dialyze, concentrate, Freeze-dry to obtain papain hydrolyzed polypeptide (PA-P).

Embodiment 3

[0026] Put the whole thorny sea bark into a drying oven, dry and crush it at 65°C, pass through a 20-mesh sieve, mix the thorny sea bark powder with distilled water at a solid-to-liquid ratio of 1:20g / ml, And add alkaline protease to it, the added alkaline protease is 5% of the quality of sea spiny caravan, after stirring evenly, adjust pH=12.0 with sodium hydroxide, and then under the condition of 50 ℃, enzyme in a constant temperature water bath Disintegrate for 8 hours to obtain the enzymatic hydrolyzate of sea spinach, put the enzymatic hydrolyzate of sea spinach in a boiling water bath for 10 minutes, and then centrifuge after cooling. Centrifugation conditions: 4000r / min, centrifuge for 15 minutes, then take the supernatant and dialyze , concentrated, and freeze-dried to obtain alkaline protease hydrolyzed polypeptide (AP-P).

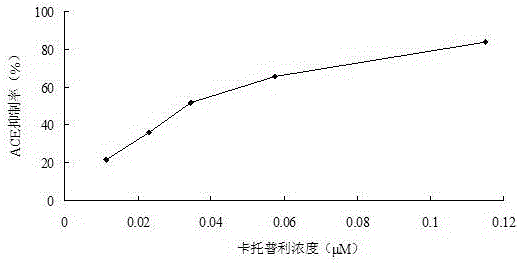

[0027] The application of the above-mentioned three kinds of sea spinach enzymatically hydrolyzed polypeptides as ACE inhibitors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half inhibitory concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com