Recovery system and recovery method for converter gas

A converter gas and recovery system technology, applied in the direction of manufacturing converters, etc., can solve the problem of lack of comparability, and achieve the effects of less recovery, avoiding waste, and improving calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] For a 158t converter in a factory, the maximum amount of molten iron charged is 155 tons / furnace, the temperature before and after the flue gas enters and exits the vaporization cooling flue 2 is around 1550°C and 750°C, the average recovery of steam is 59-86kg / t, and the flue gas contains Dust amount 67mg / m 3 Around, converter gas recovery volume maintained at 83m 3 / t±3m 3 , the calorific value of converter gas is 6.7MJ / m 3 Left and right, converter gas CO, CO 2 The contents are about 45%~65%, 20%~25%, respectively, and the restrictive conditions for converter gas recovery are CO≥35%, O 2 <2%, the recovery time is approximately 11.5 minutes from the 4th minute to the 15.5th minute of blowing, and the dust removal system adopts the OG method. The utilization rate of CDQ powder is calculated as 50%.

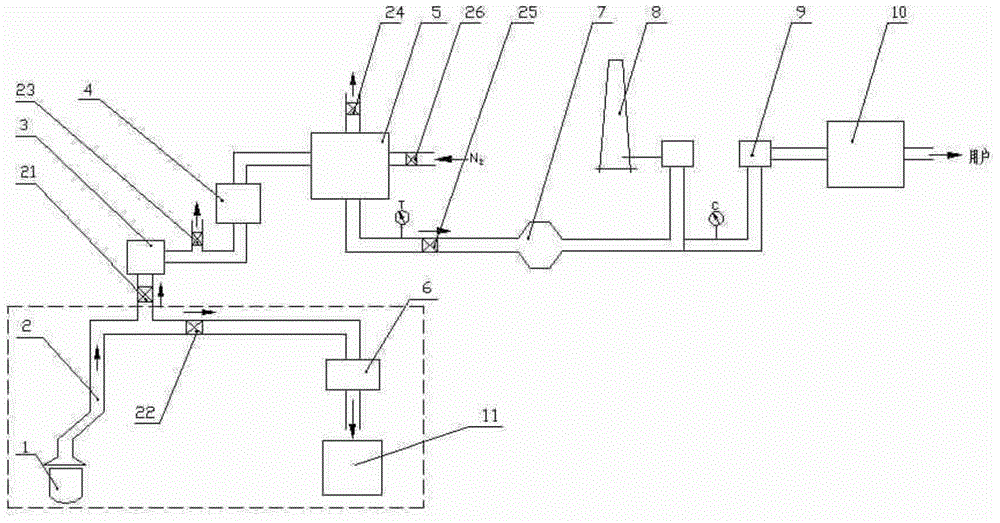

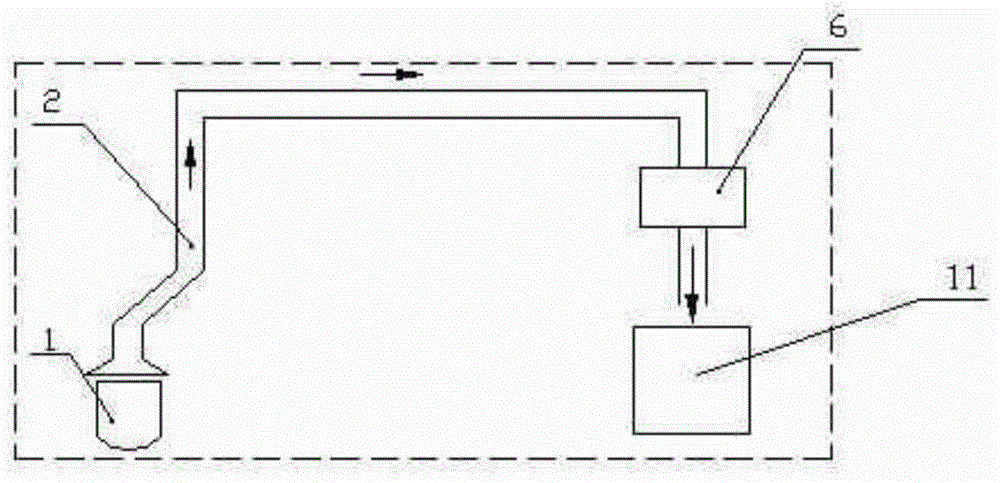

[0055] Such as figure 1 As shown, the method in which the converter gas recovery system is directly installed at the outlet end of the flue 2 of the vaporization co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com