Gas spraying head and deposition device

A gas shower head, gas technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as poor film quality, achieve the effect of reducing impurities, improving utilization, and avoiding eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As mentioned in the background art, the quality of thin films formed by existing metal-organic chemical vapor deposition devices is poor.

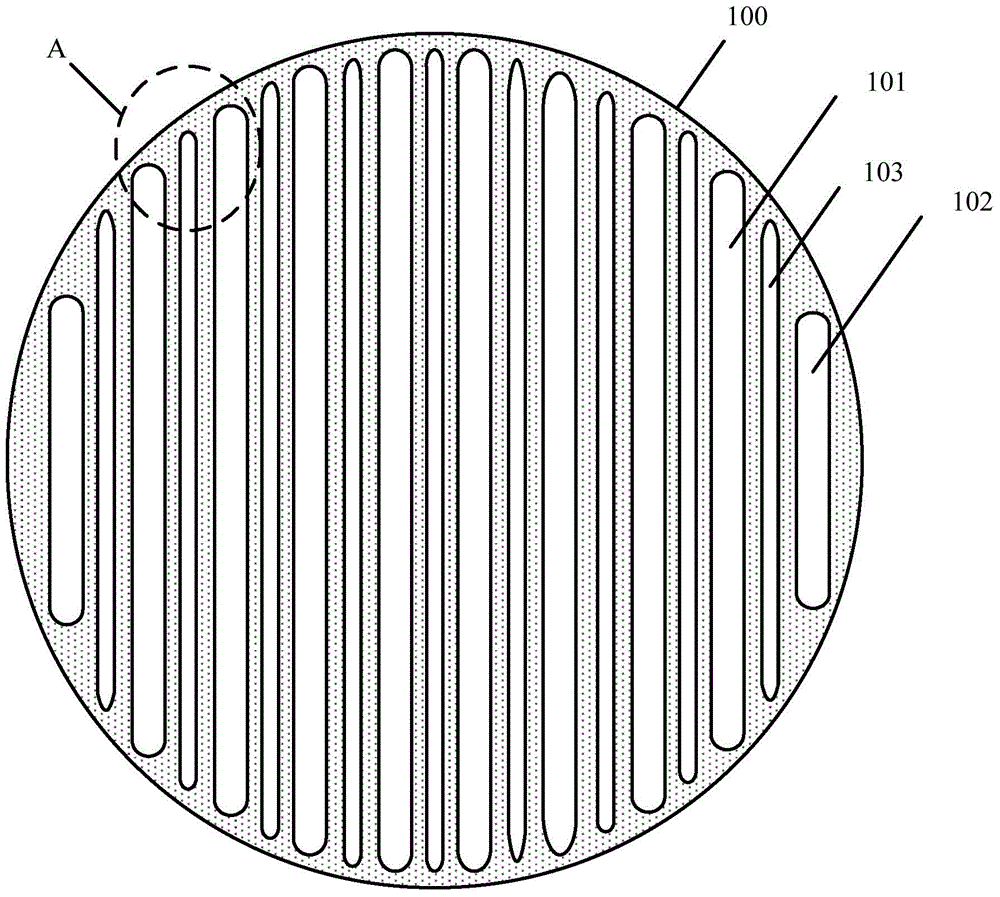

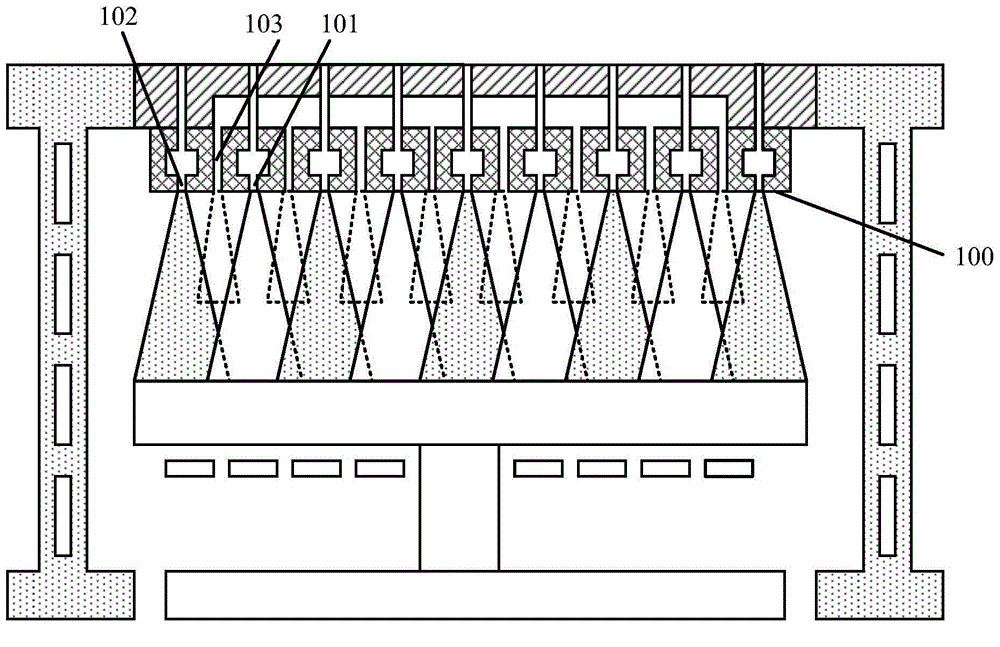

[0037] After research, please refer to figure 1 and figure 2 , figure 1 is a schematic top view structure diagram of a shower head according to an embodiment of the present invention, figure 2 is adopted figure 1 The schematic diagram of the cross-sectional structure of the metal-organic chemical vapor deposition device of the shower head shown.

[0038] The shower head includes: a shower panel 100 located at the top of the reaction chamber, the shower panel 100 includes a first shower port 101, a second shower port 102 and an interval spray port 103, the first spray port The shower outlet 101, the second shower outlet 102 and the interval shower outlet 103 are all strip-shaped, and the first shower outlet 101 and the second shower outlet 102 are successively arranged at intervals, and adjacent to the first shower outlet 101 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com