A Clean Sludge Water Pipe Extension Device Based on Three-way Valve

A clean, muddy water pipe technology, applied in the direction of valve devices, multi-way valves, cleaning hollow objects, etc., can solve the problems of environmental damage on the construction site and non-civilized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with the embodiment, the technical scheme of the present invention is described in more detail:

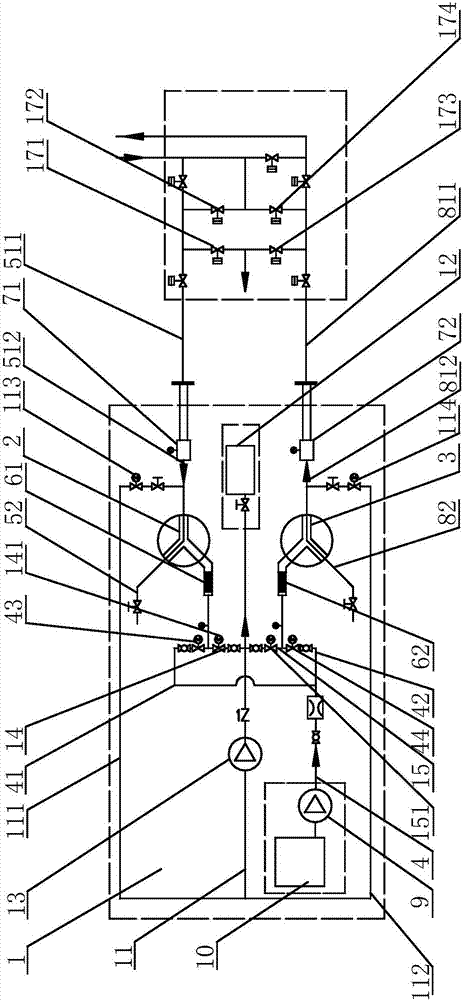

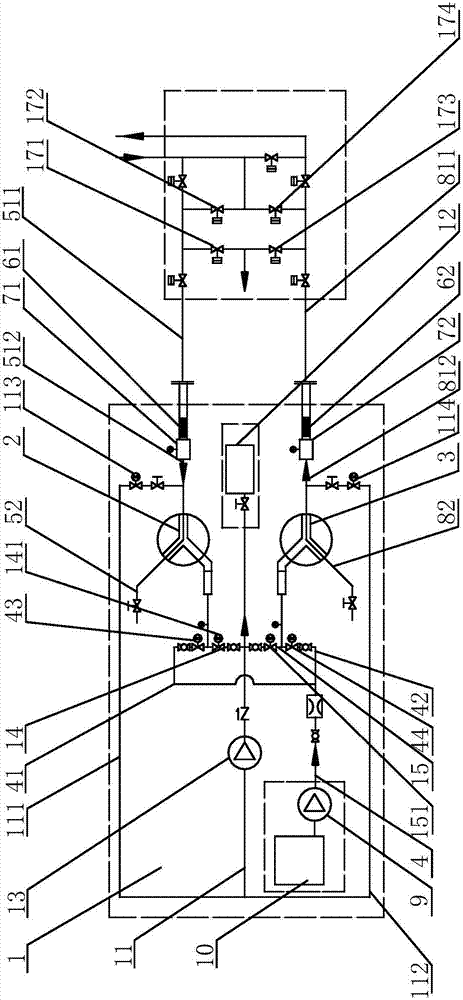

[0055] like figure 1 , 2 As shown, the present invention includes a receiver trolley 1, and the receiver trolley 1 is provided with a first three-way reversing valve 2 and a second three-way reversing valve 3;

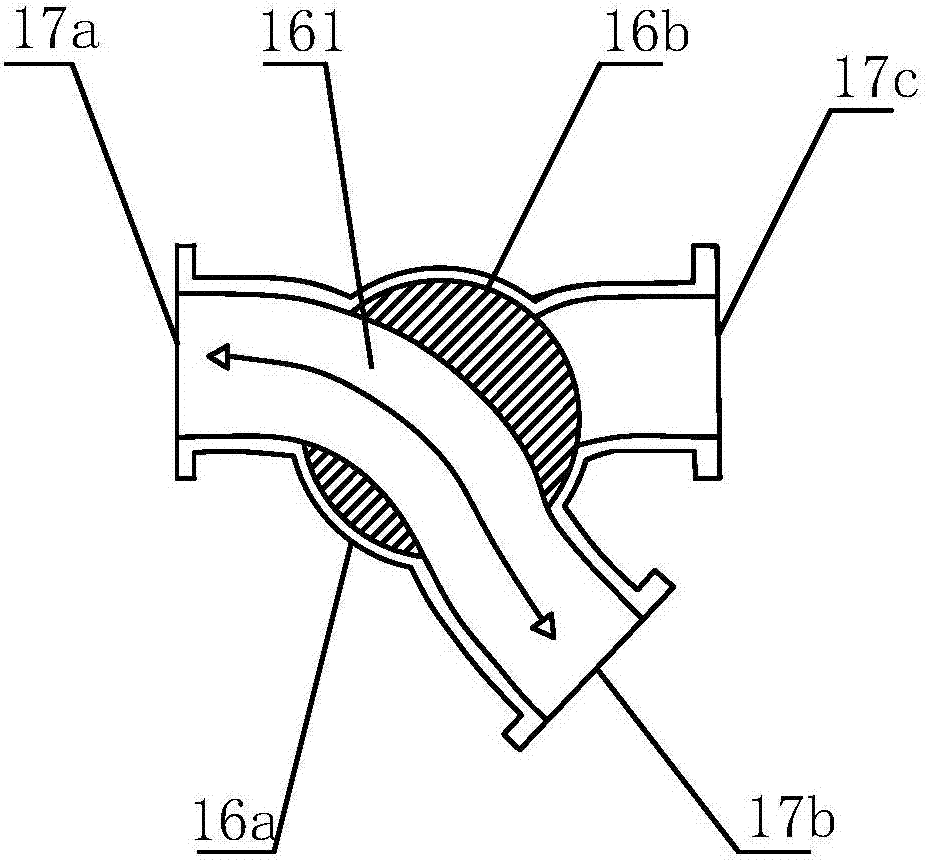

[0056] The interfaces of the first three-way reversing valve 2 are respectively communicated with the first water supply pipe 41, the first section of the mud feeding pipe and the second section 52 of the mud feeding pipe of the shield machine. The section includes the fixed pipe section 511 of the mud feeding pipe connected to each other and the walking section 512 of the mud feeding pipe that travels with the take-over trolley. A first cleaning moving plug 61 is arranged in the lumen of the first water supply pipe 41, and the first cleaning moving plug 61 enters the fixed pipe section 511 of the mud inlet pipe through the first three-way rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com