Radiator

A radiator and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

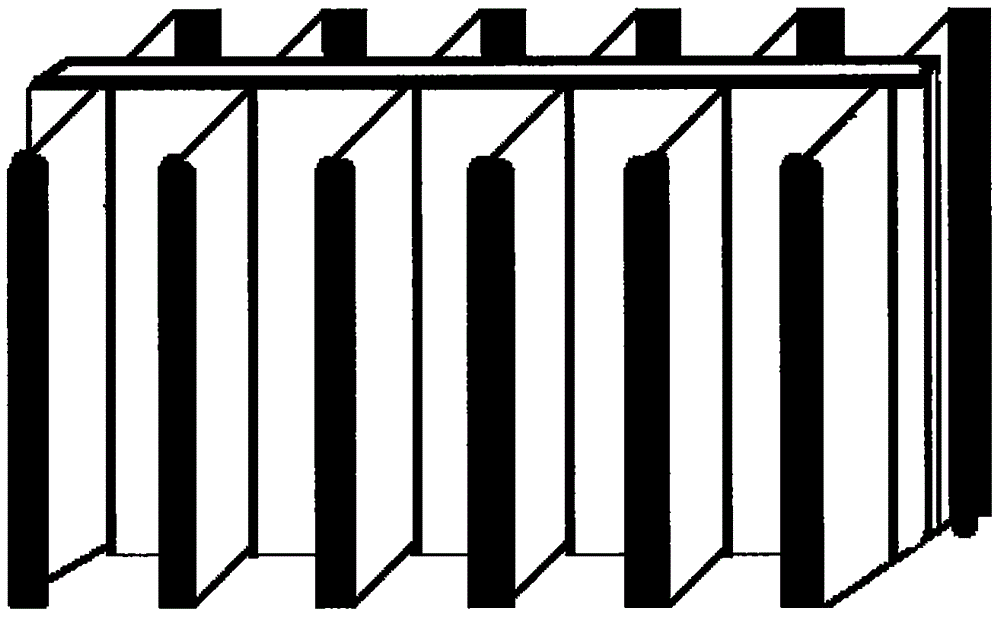

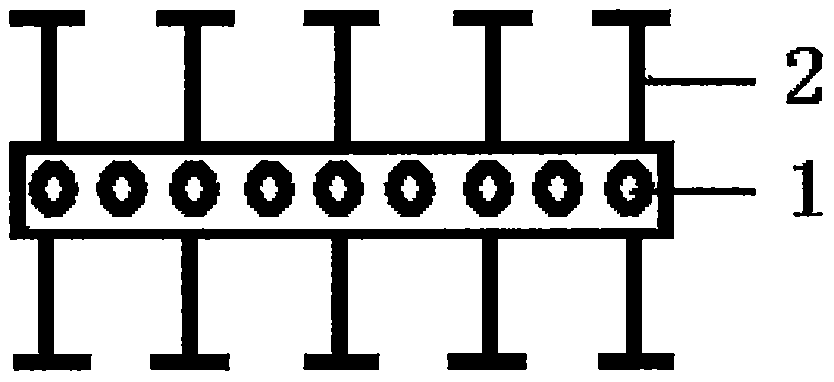

[0020] The structure of a radiator in the embodiment of the present invention is as follows: figure 1 As shown, its cross-section is shown as figure 2 shown. The heat sink of this embodiment includes an array heat pipe 1 and special-shaped fins 2 , wherein the array heat pipe 1 and the special-shaped fins 2 are integrally formed by extruding aluminum alloy processing equipment without gaps in between.

[0021] In this embodiment, the material of the array heat pipe 1 is aluminum alloy, including a plurality of independent heat pipes evenly arranged, the cavity inside the heat pipe is filled with a phase change working medium, and the cross section of the cavity inside the heat pipe is circular. Both ends of the array heat pipe 1 are welded and sealed after being vacuumed.

[0022] In this embodiment, the special-shaped fins 2 are I-shaped fins, which are arranged on both sides of the array heat pipe 1 .

[0023] In this embodiment, the I-shaped fin can also be arranged on ...

Embodiment 2

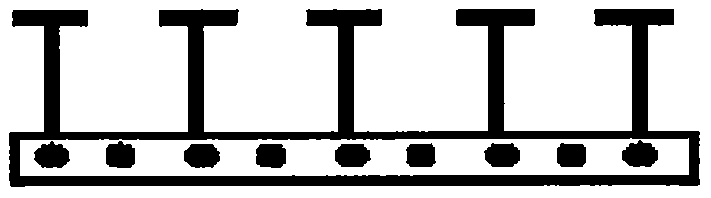

[0025] A cross-section of a heat sink according to an embodiment of the present invention is as follows: Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the special-shaped fins of this embodiment are angular fins, and the angular fins are arranged on one side of the heat pipe array. The angular fins in this embodiment can also be arranged on both sides of the heat pipe array.

Embodiment 3

[0027] A cross-section of a heat sink according to an embodiment of the present invention is as follows: Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the special-shaped fins of this embodiment are S-shaped fins, and the S-shaped fins are arranged on one side of the heat pipe array. The S-shaped fins in this embodiment can also be arranged on both sides of the heat pipe array.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com