Four-beam microstrip transmission array antenna based on super-surface, and design method for four-beam microstrip transmission array antenna

A metasurface and array antenna technology, applied in the direction of antenna, waveguide horn, radiation element structure, etc., can solve the problems of large loss, complex manufacturing and space application, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

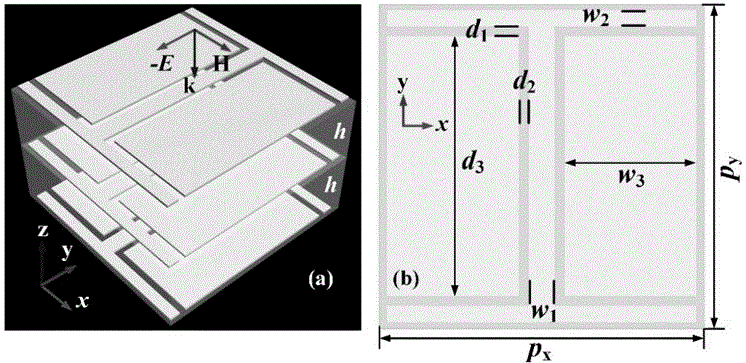

[0035] Four-beam transmission array antenna embodiment:

[0036] Such as Figure 6 As shown, the length of the waveguide is a=22.86mm, the width is b=10.16mm, and the opening diameter of the horn is A*B=44*24mm 2 , the overall height is L=30mm, a and b are the aperture size of the standard X-band waveguide BJ-100, A, B and L are determined according to impedance matching and antenna aperture size optimization.

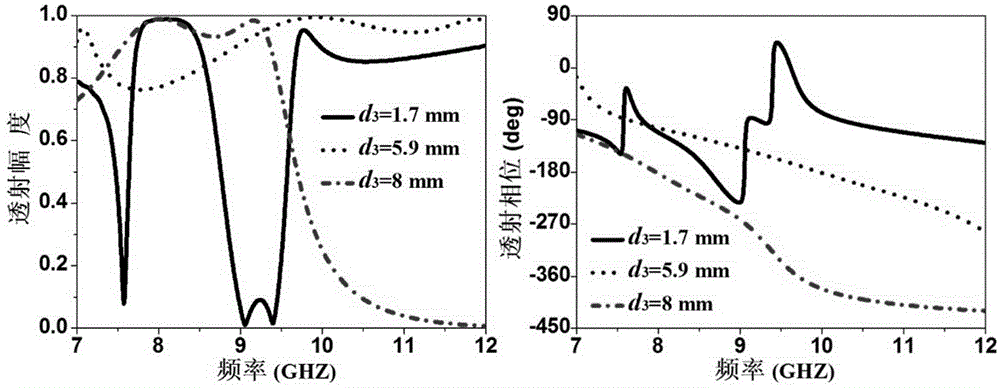

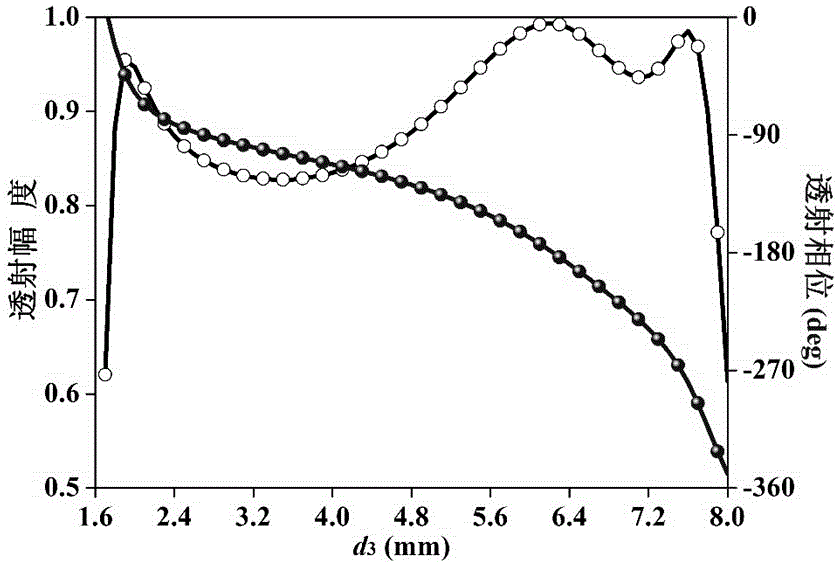

[0037] Among them, the structural parameter of the metasurface microstrip transmission array unit is p x =p y =10mm,w 1 =0.8mm, w 2 =0.5mm, w 3 =4.05mm, d 1 =D 2 =0.3mm and d 3 =8mm.

[0038] The central operating frequency of the transmission array antenna of the present invention is f 0 =9.6GHz, N=25, D=250mm, F=150mm, the elevation angles of the four beams are θ=40°, and the azimuth angles are φ 1 =0°, φ 2 =90°, φ 3 =180° and φ 4 =270°.

[0039] For verifying the correctness of the design method of the present invention, Figure 7 The theoretical opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com