Multi-spray head biological 3D printing equipment capable of batching and mixing materials automatically and control method for multi-spray head biological 3D printing equipment

A 3D printing, automatic batching technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems of difficult mixing, low work efficiency, mixing materials, etc., achieve equipment motion control and simple structure, improve printing efficiency , Easy to assemble and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific structure, working principle and working process content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

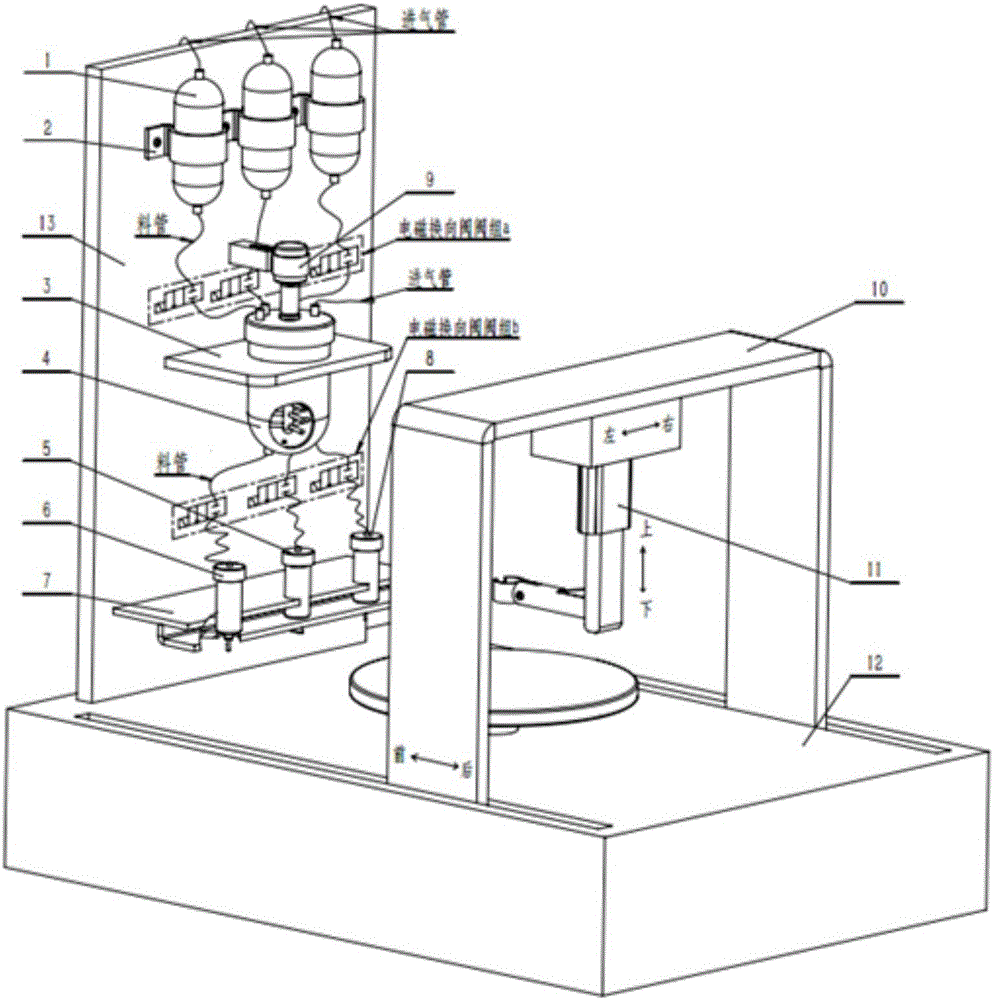

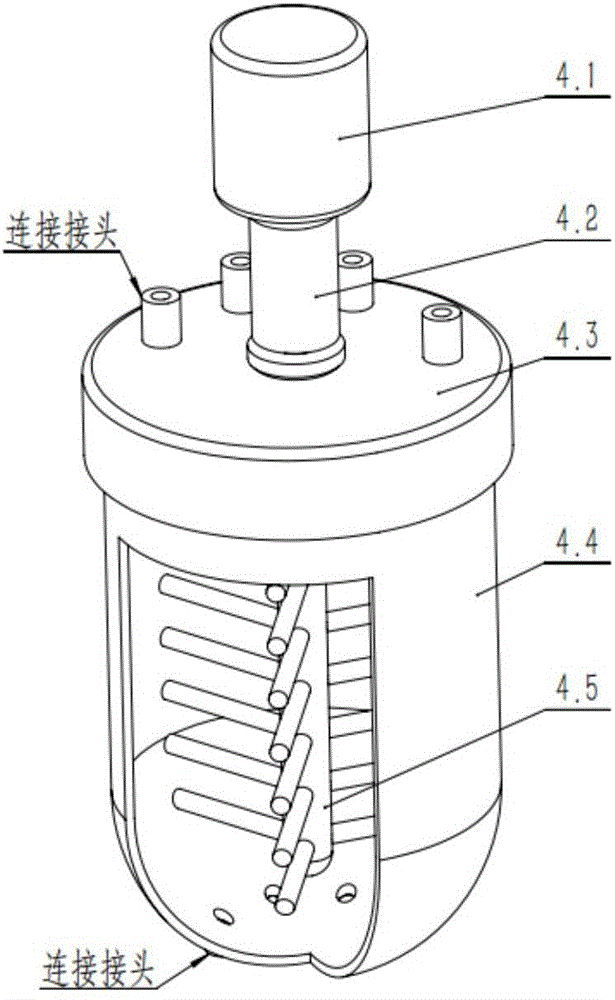

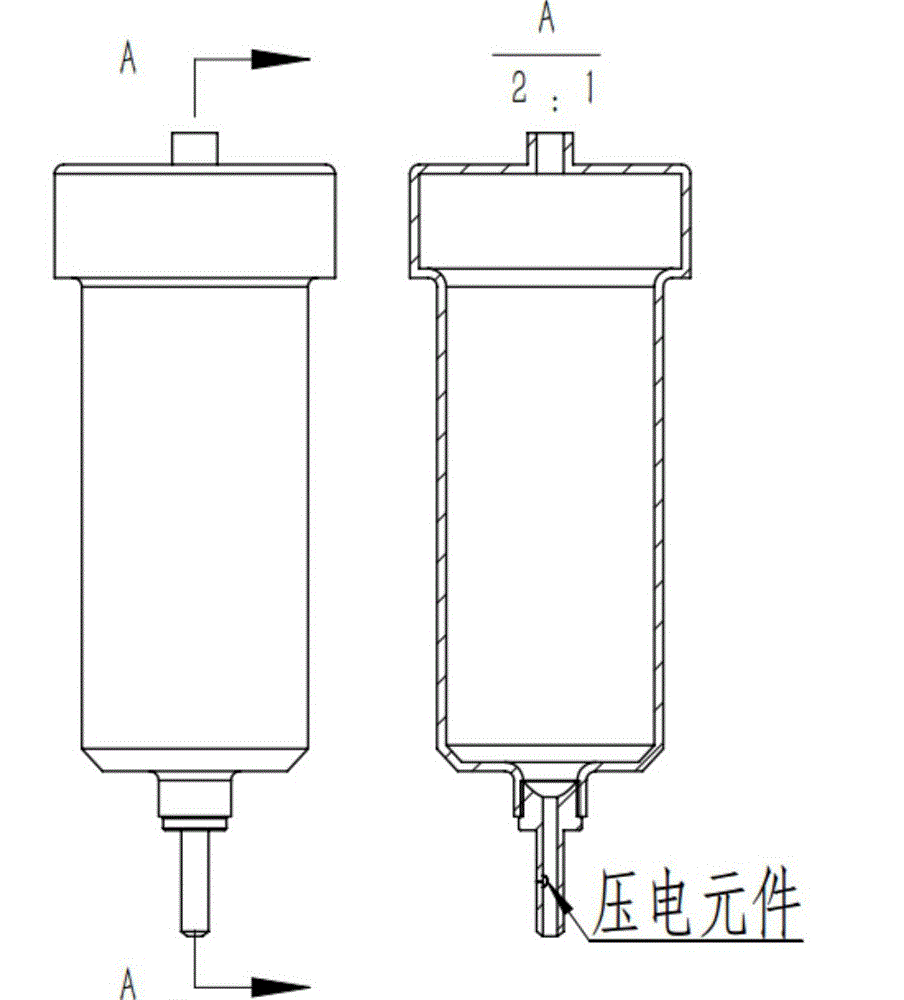

[0031] Such as Figure 1 to Figure 6 As shown, an automatic batching and mixing multi-nozzle biological 3D printing equipment includes a pneumatic pressure tank 1, a pressure tank pipe clamp 2, a fixed plate 3, an electromagnetic reversing valve valve group a, an electromagnetic reversing valve group b, a mixing tank Tank assembly 4 (such as figure 2 shown), surface spray head 5 (such as Figure 4 shown), dot nozzle 6 (such as image 3 shown), nozzle bracket 7, line nozzle 8 (such as Figure 5 shown), motor fixing frame 9, moving top beam 10, reclaiming driving arm 11 (such as Figure 6 shown), workbench 12, side plate 13; each group of said electromagnetic reversing valve valve group a and electromagnetic reversing valve valve group b is composed of at least two electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com