Formaldehyde absorption board

A formaldehyde adsorption and water layer technology, which is applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of small contact area between carbon bag and air, formaldehyde pollution, and unsatisfactory adsorption effect, so as to increase the formaldehyde removal effect, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

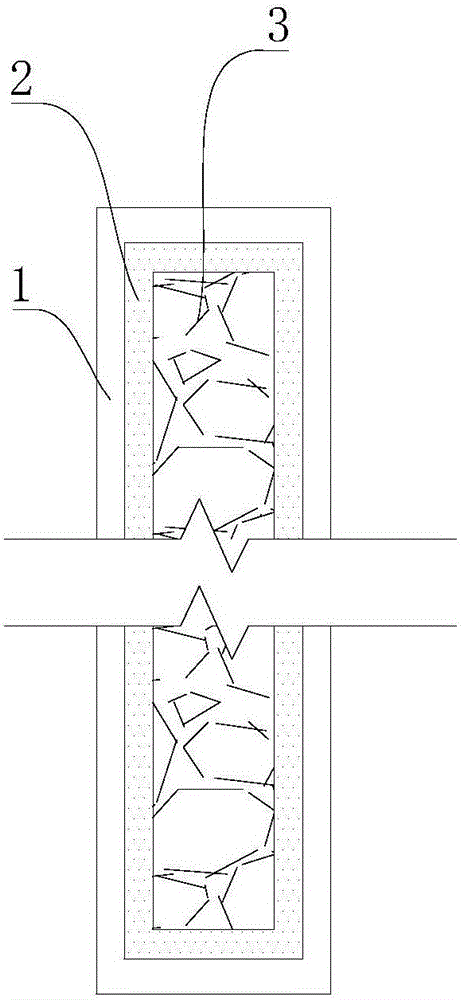

[0012] Below in conjunction with accompanying drawing and embodiment, the present invention is further described:

[0013] The formaldehyde adsorption board includes an aqueous layer 3, the aqueous layer 3 is soaked with an amino acid aqueous solution, the aqueous layer 3 is wrapped with a porous layer 2, and the porous layer 2 is wrapped with a breathable water-blocking layer 1.

[0014] The above-mentioned formaldehyde adsorption plate, in which the aqueous layer 3 is infiltrated with an amino acid aqueous solution, can be infiltrated into the pores of the porous layer 2, and the polluted air enters the porous layer 2 through the breathable water blocking layer 1 and contacts with the amino acid solution, and the formaldehyde reacts with the amino acid, To achieve the purpose of removing formaldehyde.

[0015] Specifically, the aqueous layer 3 can store and adsorb the amino acid aqueous solution, for example, it can be made of cotton, sponge or the like.

[0016] The aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com