Novel tray pelletizer

A ball making machine and tray technology, applied in the direction of granulation in rotating discs/pots, can solve the problems of resource waste, limited edge height, ball rolling, etc., to extend service life, prevent material waste, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

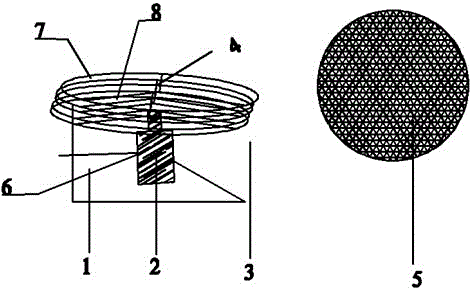

[0019] like figure 1 As shown, a new type of tray pelletizing machine, including a base 1, a motor 2, and a disc system 3, is characterized in that: the disc system 3 is provided with a multi-angle scraper 4; the blade 4 of the scraper is irregular of gears.

Embodiment 2

[0021] Example 2 as figure 1 Shown, it is improved on the basis of embodiment 1, and in its disc system, the height of the disc 3 edges is 10-15 centimeters; The disc shading is a regular quadrilateral. Through the standard quadrilateral disc, the pellet product can be known more regularly, and at the same time, the use of a suitable disc edge will not cause the pellets to overflow.

Embodiment 3

[0023] Example 3 as figure 1 As shown, it is improved on the basis of Embodiment 1, and its scraper 4 is made to cooperate with disc clearance for galvanized stainless steel alloy. The galvanized stainless steel material has high strength, good wear resistance and no pollution. It is suitable for occasions with frequent sliding friction. At the same time, it cooperates with the gap between the discs to protect the discs from being damaged by wear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com