Single-power multi-wire welding machine and its control method for alternation of non-extinguishing welding wire

A control method and alternating conversion technology, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of inability to change the welding wire, etc., and achieve the effect of reducing molding efficiency, reasonable and compact hardware structure design, and reducing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

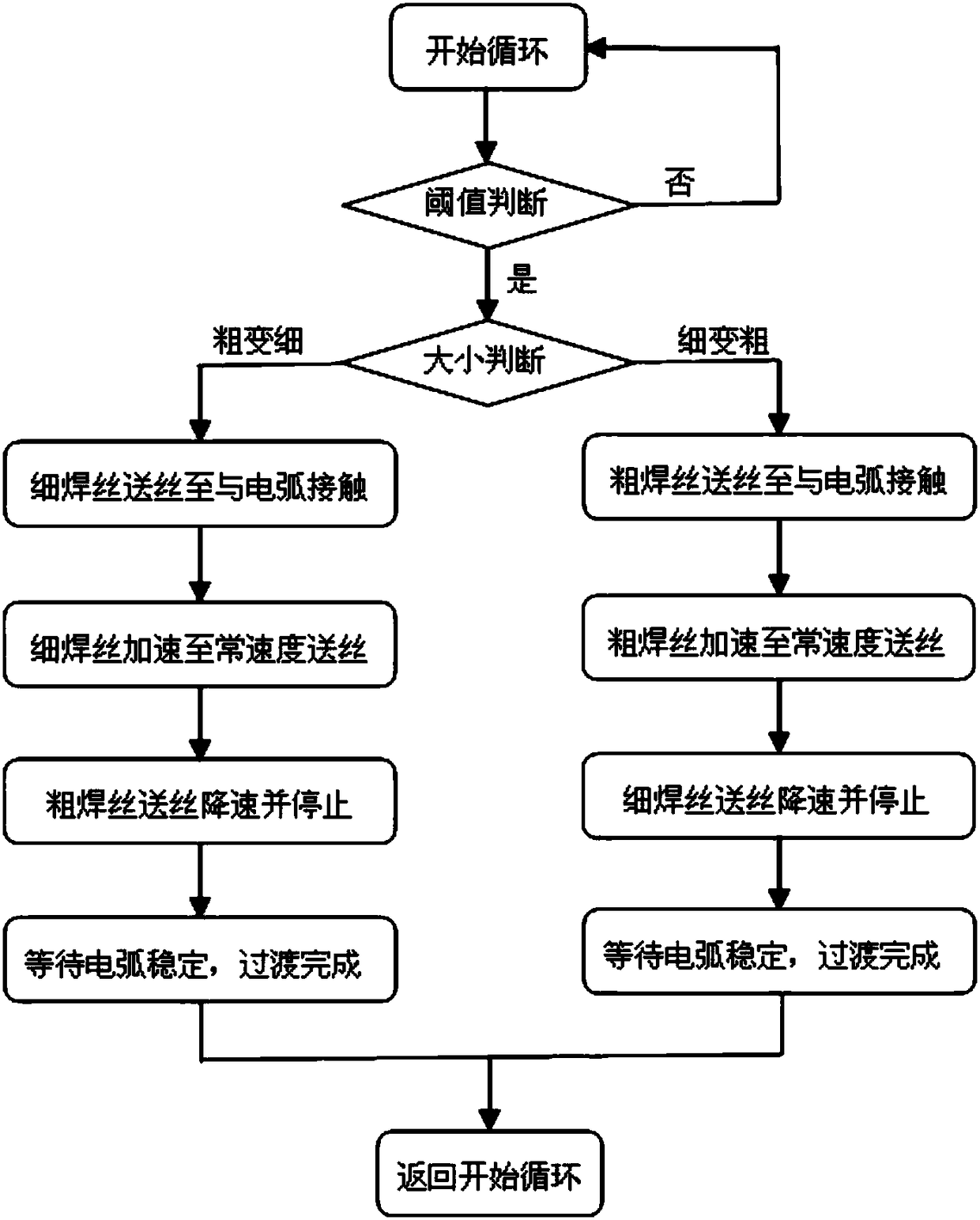

Method used

Image

Examples

specific Embodiment approach

[0027] The single power supply multi-wire welding machine of the present invention, its preferred embodiment is:

[0028] Including wide welding specification inverter power supply, conventional welding wire wire feeder, thin welding wire short-distance wire feeder, single contact tip double wire or multi-wire welding torch;

[0029] The wide welding specification inverter power supply is connected to the conventional welding wire feeder and the fine welding short distance wire feeder through the wire feeder control cable, and the conventional welding wire feeder and the fine welding short distance wire feeder are respectively controlled by Thick wire feed tube and short distance fine wire feed tube are connected to the single contact tip double wire or multi wire welding torch, the single contact tip double wire or multi wire welding gun is connected with the output electrode of the wide welding specification inverter power supply One of the poles is connected by a welding ca...

specific Embodiment

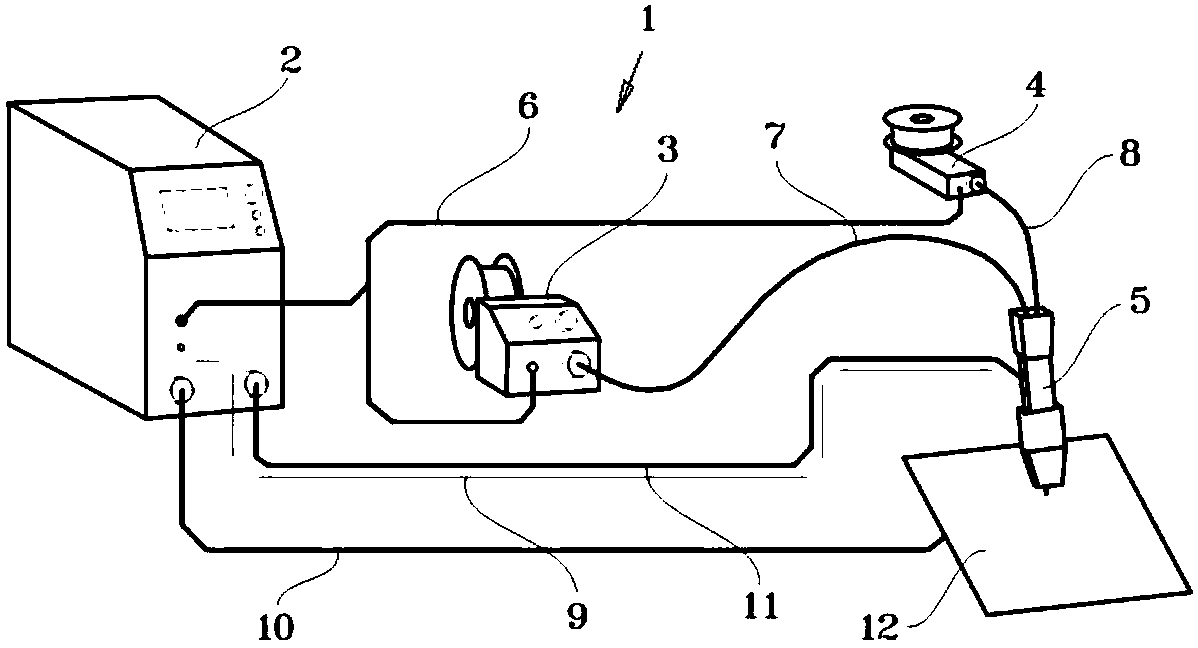

[0050] Such as figure 1 As shown, the multi-purpose single-power multi-wire welding machine 1 of the equipment hardware part of the present invention includes: a wide welding standard inverter power supply 2, a conventional welding wire feeder 3, a thin welding wire short-distance wire feeder 4, a single conductive tip double wire Or multi-wire welding torch 5, wire feeder control cable 6, thick wire feeding tube 7, short-distance thin wire feeding tube 8, shielding gas hose 9, base metal cable 10, welding cable 11 and other parts.

[0051] The main body of the single-power multi-wire welding machine 1 is a wide welding specification inverter power supply 2, and the wide welding specification inverter power supply 2 is controlled by the conventional welding wire feeder 3 and the thin welding wire short-distance wire feeder 4 through the wire feeder The conventional welding wire feeder 3 and the thin wire short-distance wire feeder 4 are respectively connected to the single con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com