Mechanical arm moving control system for automatic lathe

A technology of robotic arm and control system, which is applied in the direction of manipulator, program control manipulator, manufacturing tools, etc. It can solve the problems of unreliable quality and precision guarantee, high cost of lathe, and reduce labor intensity, etc., and achieve rich settings, convenient and safe storage and Manage and realize the effect of remote control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

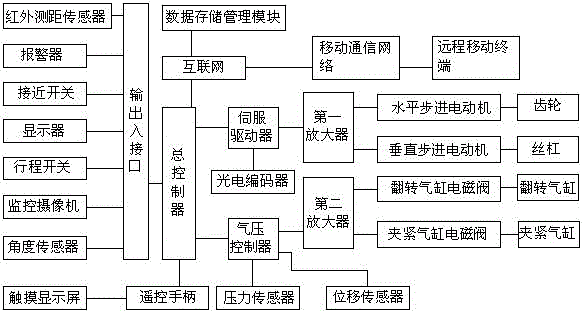

[0013] Such as figure 1 Shown, a kind of mechanical arm movement control system of automatic lathe, it comprises master controller, and described master controller is connected with input and output interface, remote control handle, servo driver, air pressure controller and Internet, and described output and output interface An infrared distance measuring sensor, an alarm, a proximity switch, a display, a travel switch, a monitoring camera and an angle sensor are connected, the remote control handle is connected with a touch screen, and the servo driver is connected with a photoelectric encoder and a first amplifier, The first amplifier is connected with a horizontal stepping motor and a vertical stepping motor, and the horizontal stepping motor and the vertical stepping motor are respectively connected with a gear and a lead screw, and the air pressure controller is connected with a pressure sensor, a displacement The sensor and the second amplifier, the second amplifier is c...

Embodiment 2

[0016] Such as figure 1 Shown, a kind of mechanical arm movement control system of automatic lathe, it comprises master controller, and described master controller is connected with input and output interface, remote control handle, servo driver, air pressure controller and Internet, and described output and output interface An infrared distance measuring sensor, an alarm, a proximity switch, a display, a travel switch, a monitoring camera and an angle sensor are connected, the remote control handle is connected with a touch screen, and the servo driver is connected with a photoelectric encoder and a first amplifier, The first amplifier is connected with a horizontal stepping motor and a vertical stepping motor, and the horizontal stepping motor and the vertical stepping motor are respectively connected with a gear and a lead screw, and the air pressure controller is connected with a pressure sensor, a displacement The sensor and the second amplifier, the second amplifier is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com