Synthetic method of 2,5-dichlorophenol

A technology of dichlorophenol and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of low utilization rate of raw materials, high utilization rate of raw materials and high industrial cost, and achieve high utilization rate of raw materials , The effect of low production cost and low production of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

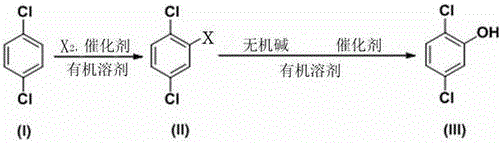

[0036] A kind of synthetic method of 2,5-dichlorophenol, comprises the following processing steps:

[0037] A, under the condition of catalyst, pass into chlorine gas in pure benzene, obtain 1,2,4-trichlorobenzene and p-dichlorobenzene;

[0038] B, the 1,2,4-trichlorobenzene obtained in step A is formulated into a solution, hydrolyzed and purified to obtain 2,5-dichlorophenol;

[0039] C, the p-dichlorobenzene obtained in step A is reacted with a halogen to generate 2,5-dichlorohalobenzene, and then hydrolyzed to obtain 2,5-dichlorophenol;

[0040] Alternatively, the p-dichlorobenzene obtained in step A is treated with a Lewis acid, and then under the condition of a catalyst, chlorine gas is passed into the p-dichlorobenzene treated by the Lewis acid to obtain 1,2,4-trichlorobenzene, Then formulated into a solution, hydrolyzed and purified to obtain 2,5-dichlorophenol.

Embodiment 2

[0042] On the basis of embodiment 1:

[0043] Preferably, in step A, specifically: using antimony sulfide as a catalyst, chlorine gas is introduced into pure benzene at a reaction temperature of 60°C; wherein, the ratio of chlorine gas to pure benzene is 2.5:1; The mass ratio of antimony sulfide to pure benzene is 0.001:1.

Embodiment 3

[0045] On the basis of embodiment 1:

[0046] Preferably, in step A, specifically: using antimony sulfide as a catalyst, chlorine gas is introduced into pure benzene at a reaction temperature of 65°C; wherein, the ratio of chlorine gas to pure benzene is 3:1; The mass ratio of antimony sulfide to pure benzene is 0.05:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com