Organic/inorganic hybridized cuprous iodine anion high-polymeric chain-based semiconductor material

A semiconductor and anion technology, applied in the field of semiconductor materials and iodide-based semiconductor materials, to achieve the effects of low production cost, high yield, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A large number of organic-inorganic hybrid cuprous iodide anion polymer chain-based semiconductor materials (MV) n (Cu 2 I 4 ) n Preparation of crystal samples: Weigh 0.191g (1mmol) of cuprous iodide and dissolve it in 30ml of acetonitrile to obtain a clear solution A, weigh 0.222g (0.5mmol) of methyl viologen iodide and dissolve it in 5ml of water to obtain a clear solution solution B; then, the above solution B was added to the solution A to form turbidity immediately, and the stirring reaction was continued for half an hour after the addition was completed to form a large amount of crystal products, filtered to separate out the crystals, and then washed twice with water and ethanol, respectively, and vacuum-dried to finally obtain A large number of black crystals are the target product of the hybrid material, and the yield exceeds 80%.

Embodiment 2

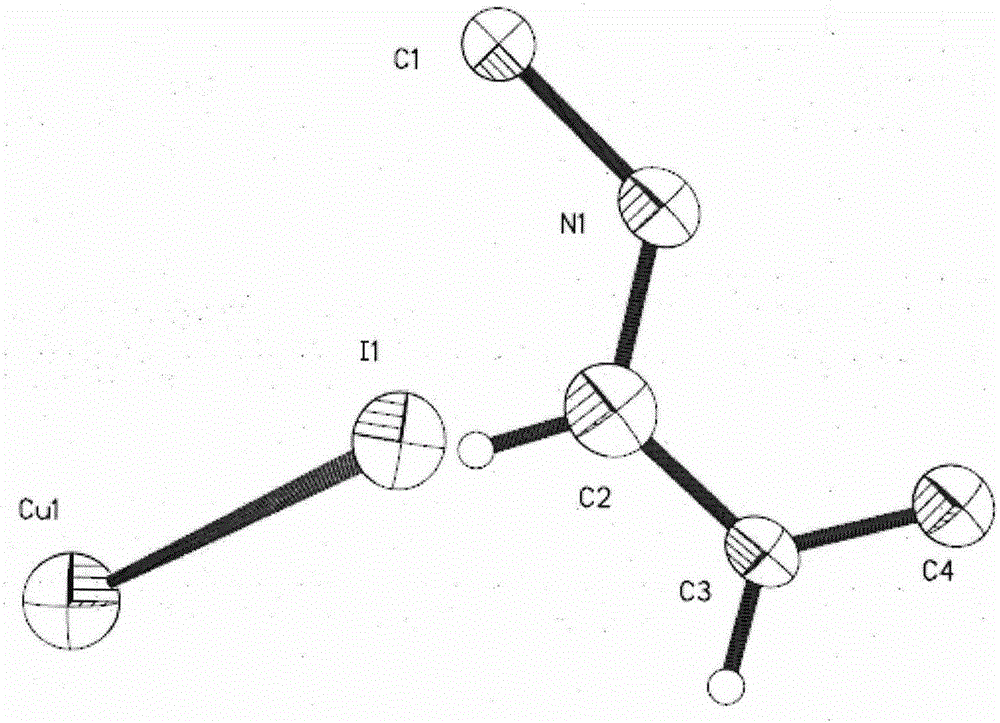

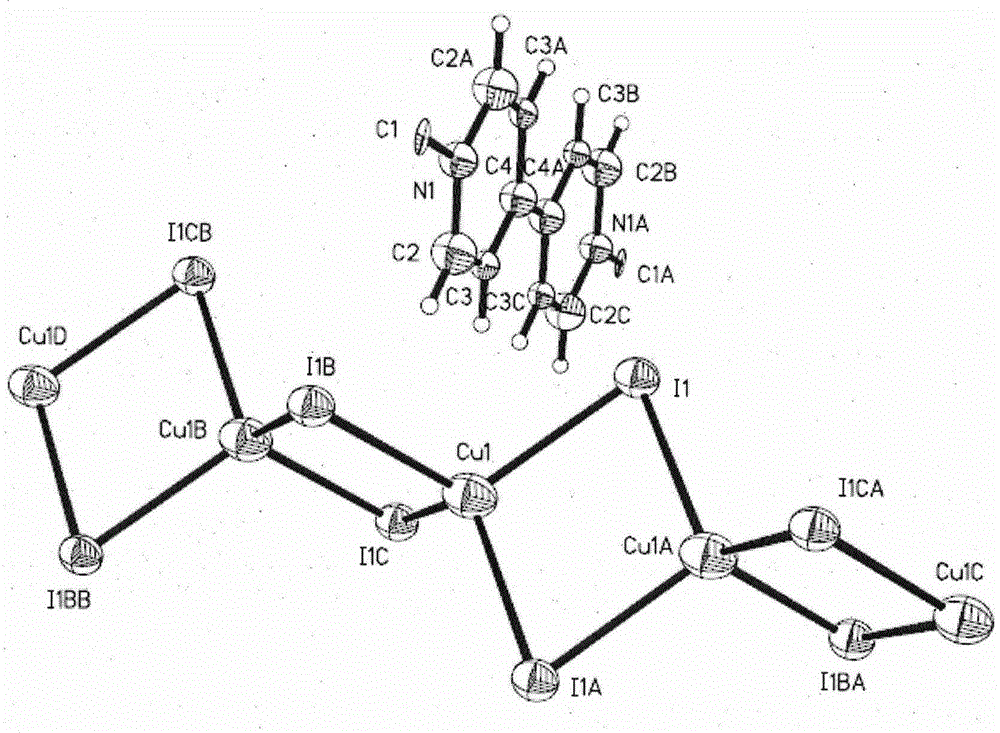

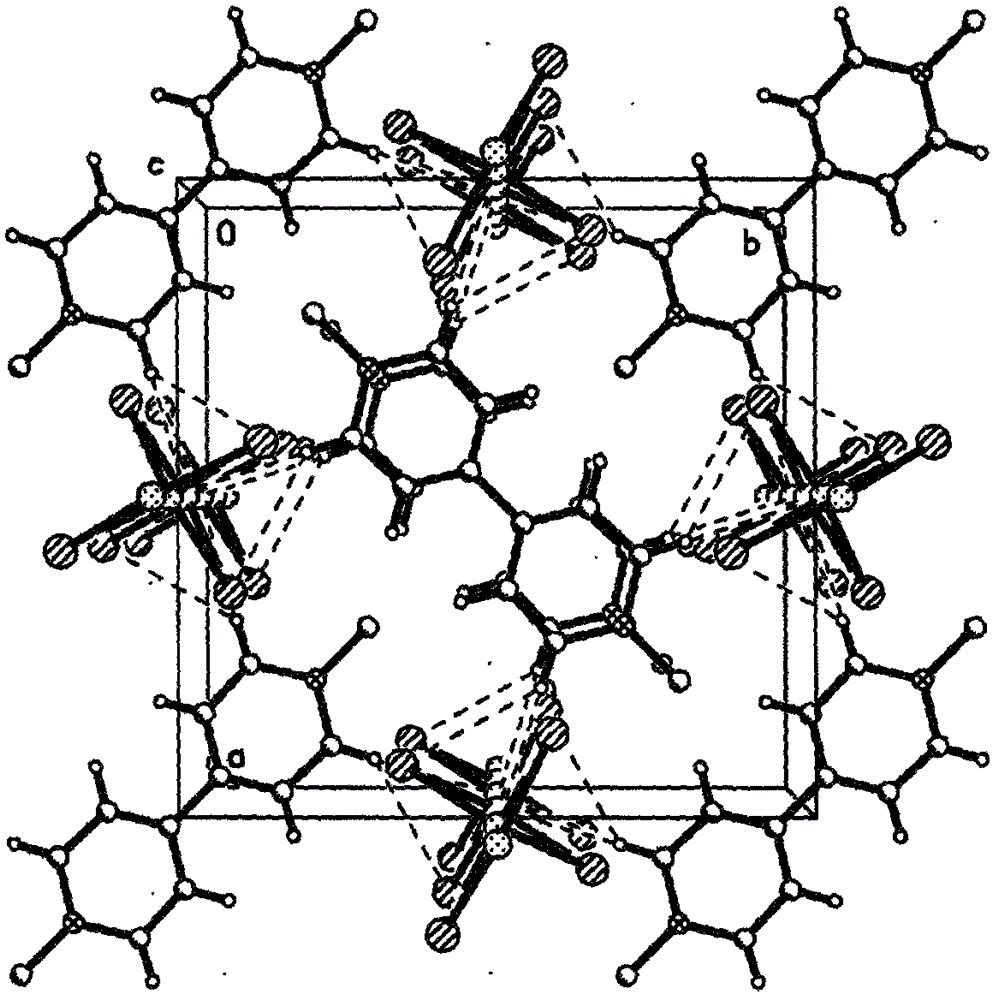

[0029] Synthesis of organic-inorganic hybrid cuprous iodide anion polymer chain-based semiconductor material (MV) n (Cu 2 I 4 ) n Single crystal: Weigh 19 mg (0.1 mmol) of cuprous iodide and dissolve it in 5 ml of acetonitrile to obtain a clear solution A, weigh 22 mg (0.05 mmol) of methyl viologen iodide and dissolve it in 5 ml of water to obtain a clear solution B ; Then, put solution B in the test tube first, then slowly add solution A to the test tube to make it in the upper layer of solution B, seal the test tube and let it stand, after a few days, a large number of black block crystals are precipitated. A black bulk crystal with a size of 0.18mm*0.12mm*0.10mm was selected for X-ray single crystal structure testing. The structure diagram of the crystallographically independent unit of this compound is shown in the appendix figure 1 , the structure of its cuprous iodide anion polymer chain and the corresponding counter cation methyl viologen are shown in the appendix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com