Waterborne epoxy anticorrosive antirust paint and preparation method thereof

An anti-corrosion and anti-rust, water-based epoxy technology, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., to achieve high adhesion, easy access to raw materials, and better anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

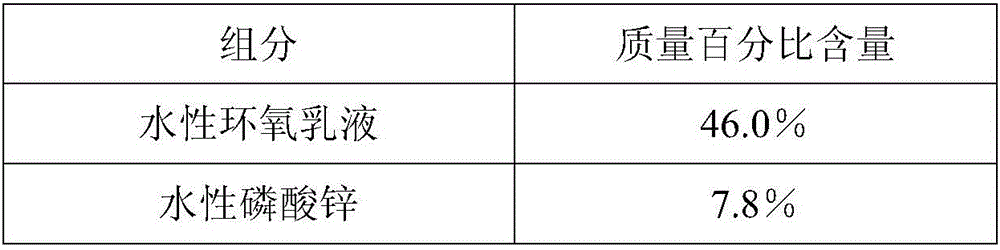

[0019] A water-based epoxy anti-corrosion and anti-rust paint, based on water-based epoxy emulsion, adding various pigments, fillers and additives, the components and their mass percentages are as follows:

[0020] components

Mass percentage content

54.0%

6.0%

Modified aluminum tripolyphosphate

3.0%

10.0%

Coalescent

2.0%

Water-based defoamer

1.0%

Thickener SN-636

2.0%

Wetting agent PE-100

2.0%

Bactericidal preservatives

2.0%

Anti-flash rust agent

2.0%

Dispersant 5040

1.5%

leveling agent

2.5%

Deionized water

12.0%

[0021] According to the preparation method of the water-based epoxy anti-corrosion and anti-rust paint, according to the mass percentage content, the modified aluminum tripolyphosphate and the water-based zinc phosphate are first mixed...

Embodiment 2

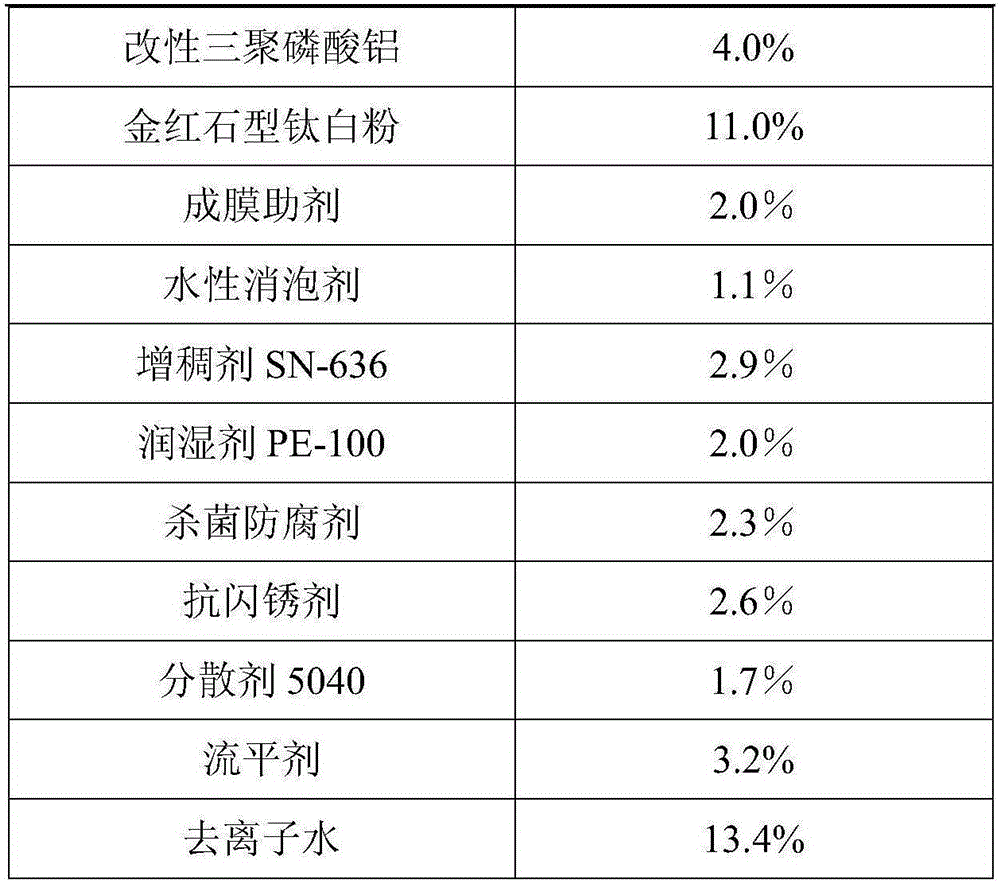

[0024] A water-based epoxy anti-corrosion and anti-rust paint, based on water-based epoxy emulsion, adding various pigments, fillers and additives, the components and their mass percentages are as follows:

[0025] components

[0026] The preparation method of described water-based epoxy anti-corrosion and rust-proof paint and the preparation method of water-based epoxy emulsion are the same as embodiment 1.

Embodiment 3

[0028] A water-based epoxy anti-corrosion and anti-rust paint, based on water-based epoxy emulsion, adding various pigments, fillers and additives, the components and their mass percentages are as follows:

[0029]

[0030]

[0031] The preparation method of described water-based epoxy anti-corrosion and rust-proof paint and the preparation method of water-based epoxy emulsion are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com