A kind of fermented honey yellow skin wine and production method thereof

A production method and fermented technology, which is applied in the field of fermented honey yellow skin wine and its production, can solve the problems of inability to release polysaccharides, high-quality tannin tartar crystal stability, lack of fruity substances and esters in honey yellow skin wine, The problem of inconsistency between the aroma of fruit wine and fruit aroma, etc., to achieve the effect of promoting the stability of tartar crystals, unique taste and flavor, and not easy to secondary turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049](1) Composite enzymatic hydrolysis: first crush the selected and cleaned seedless yellow skin with a beater, then move it into the dipping tank, and add impregnating enzyme (Vinoy FCE, French Nuomo Group) into the dipping tank for enzymatic The enzymolysis condition is 21.3°C for 6.7 hours; then add clarification enzyme (Nuo Qingbai, France Nuomo Group) for enzymolysis, and the enzymolysis condition is 17.5°C for 4 hours; wherein, the impregnated enzyme is used in the enzymatic hydrolysis system The final concentration is 25mg / L, and the clarification enzyme is added at a final concentration of 37mg / L in the enzymatic hydrolysis system.

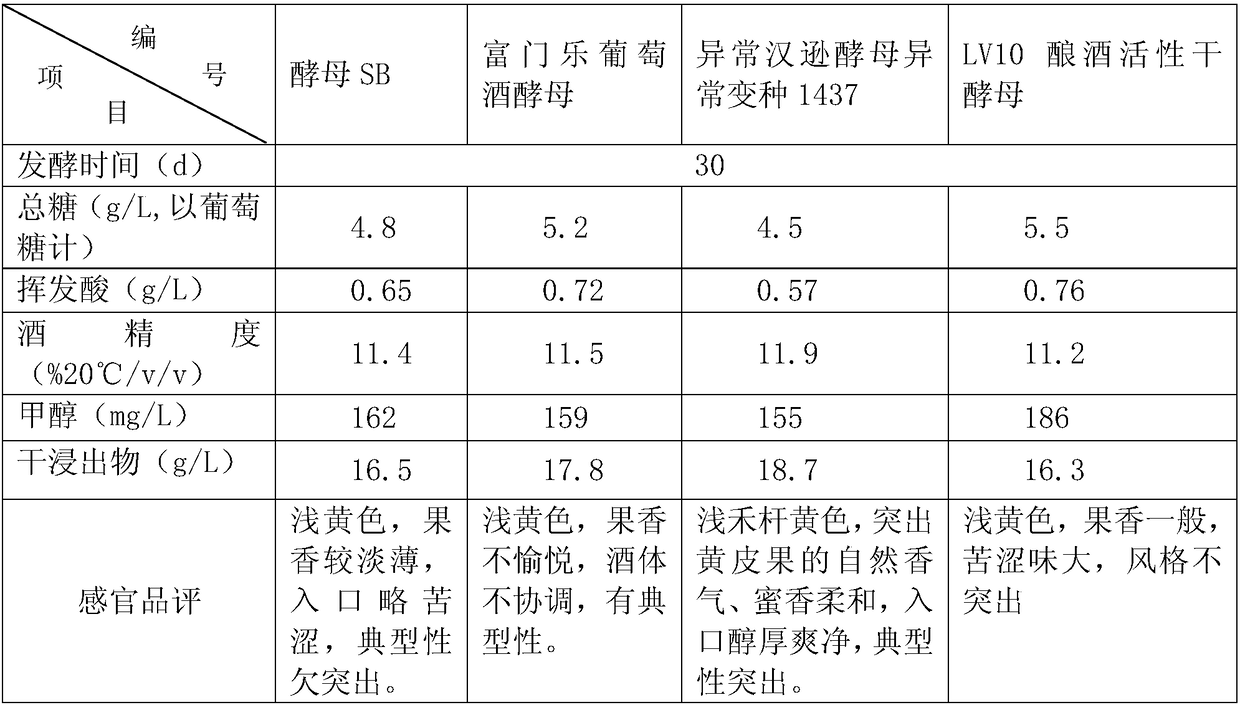

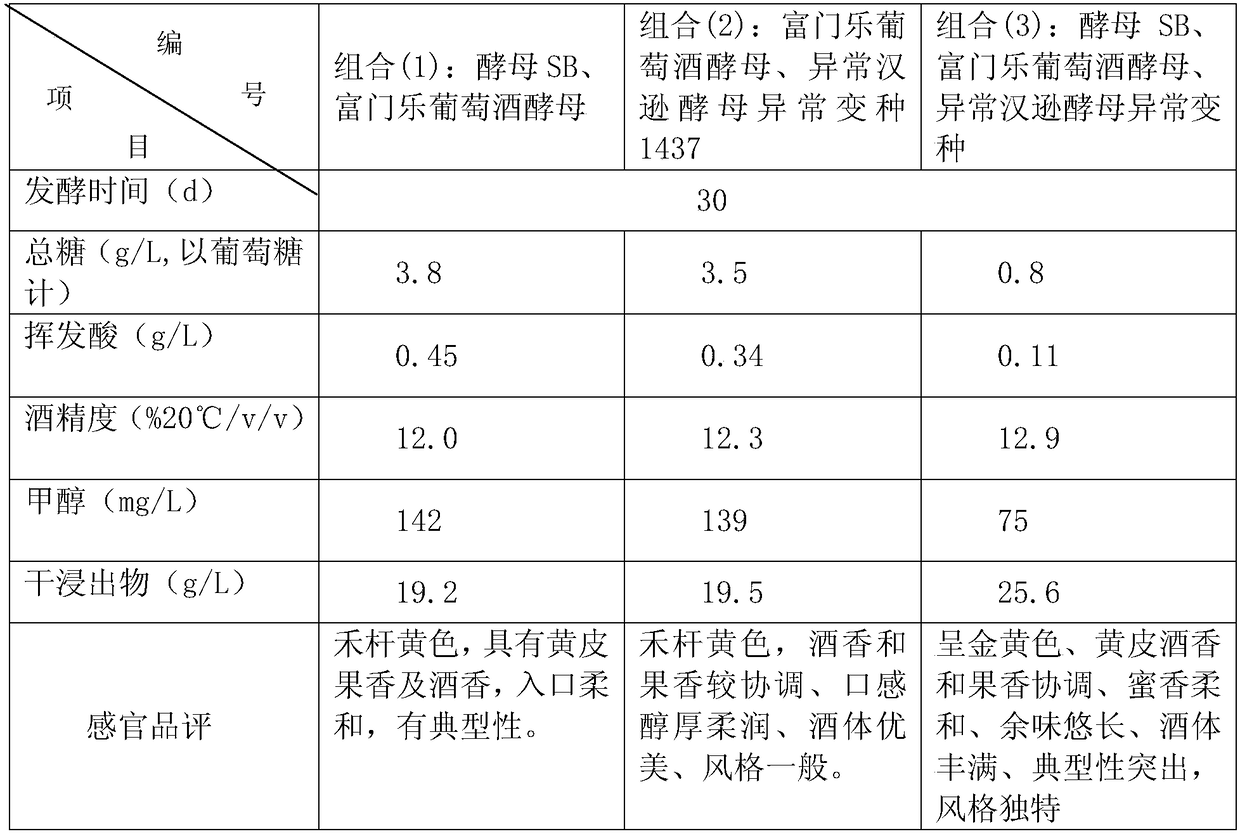

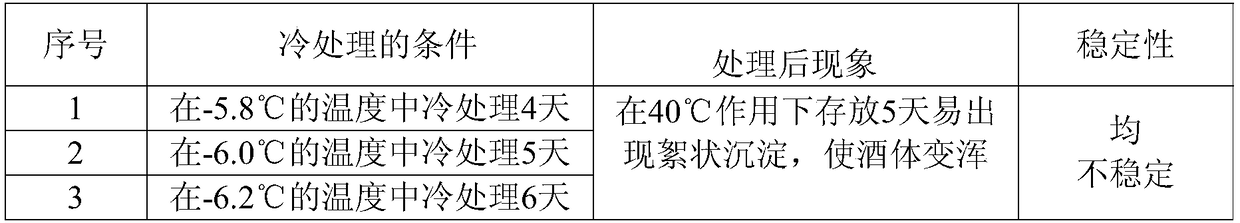

[0050] (2) Low temperature fermentation of multi-strain mixed yeast: add 0.46g / L multi-strain mixed yeast (yeast SB (ENARTIS FERM SB) of Enartis Company, Qingdao Weinuo) to the enzymolyzed product obtained in step (1) Fumenle wine yeast from Pu Trading Co., Ltd. and Hansenula anomala var.anomala 1437 from China Industrial Microbiology C...

Embodiment 2

[0058] (1) Composite enzymatic hydrolysis: first crush the selected and cleaned seedless yellow skin with a beater, then move it into the dipping tank, and add impregnating enzyme (Vinoy FCE, French Nuomo Group) into the dipping tank for enzymatic The enzymatic hydrolysis condition is 21.8°C for 7.2 hours; then add clarification enzyme (Nuo Qingbai, France Nuomo Group) for enzymolysis, the enzymatic hydrolysis condition is 18°C for 4.5 hours; wherein, the impregnated enzyme is used in the enzymatic hydrolysis system The final concentration of medium is 27.5mg / L, and the clarification enzyme is added according to the final concentration of 40.5mg / L in the enzymatic hydrolysis system.

[0059] (2) Low-temperature fermentation of multi-strain mixed yeast: add 0.49g / L multi-strain mixed yeast (yeast SB (ENARTIS FERM SB) of Enartis Company, Qingdao Weinuo) to the enzymolyzed product obtained in step (1) Fumenle wine yeast from Pu Trading Co., Ltd. and Hansenula anomala var.anomal...

Embodiment 3

[0067] (1) Composite enzymatic hydrolysis: first crush the selected and cleaned seedless yellow skin with a beater, then move it into the dipping tank, and add impregnating enzyme (Vinoy FCE, French Nuomo Group) into the dipping tank for enzymatic The enzymatic hydrolysis condition is 22.3°C for 7.7 hours; then add clarification enzyme (Nuo Qingbai, France Nuomo Group) for enzymolysis, the enzymatic hydrolysis condition is 18.5°C for 5 hours; wherein, the impregnated enzyme is used in the enzymatic hydrolysis system Add at a final concentration of 30mg / L, and add clarified enzyme at a final concentration of 44mg / L in the enzymatic hydrolysis system.

[0068] (2) Low-temperature fermentation of multi-strain mixed yeast: add 0.52 g / L multi-strain mixed yeast (yeast SB (ENARTIS FERM SB) of Enartis Company, Qingdao Weinuo) to the enzymolyzed product obtained in step (1) Fumenle wine yeast from Pu Trading Co., Ltd. and Hansenula anomala var.anomala 1437 from China Industrial Microb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com