Curved shallow-crossing linking structure carbon fiber/copper fiber carbon-based friction material and preparation method thereof

A friction material, shallow cross-bending technology, applied in the direction of carbon fiber, fiber treatment, fabric, etc., can solve the problems of difficult to bear large torsional moment, poor structural integrity, easy delamination and damage, and achieve mechanical strength improvement, bending resistance, etc. Strength and shear strength enhancement, effectiveness in overcoming delamination problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A carbon fiber / copper fiber carbon-based friction material with a shallow cross-bending structure. The preparation method of the friction material includes the following steps:

[0033] (1) Preparation of carbon fiber / copper fiber prefabricated body with shallow cross-bending structure:

[0034] ① warp yarn, 1 strand of 1650dtex copper fiber is parallel twisted, and the twist is 4 twists / 10cm, as the warp yarn;

[0035] ② Weft yarn, the carbon fiber and copper fiber are twisted and plied as the weft yarn; the following formula is used for the weft yarn to determine the mass fraction of carbon fiber and copper fiber:

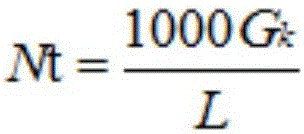

[0036] N t = 1000 G k L

[0037] In the formula, Nt-represents the linear density of the yarn, tex; Gk-represents the weight of the yarn at a given moisture regain, g; L-represents the length of the yarn, m; the mixing...

Embodiment 2

[0045] A carbon fiber / copper fiber carbon-based friction material with a shallow cross-bending structure. The preparation method of the friction material includes the following steps:

[0046] (1) Preparation of carbon fiber / copper fiber prefabricated body with shallow cross-bending structure:

[0047] ① Warp yarn, 5 strands of 1650dtex copper fiber are parallel twisted, and the twist is 7 twists / 10cm, as the warp yarn;

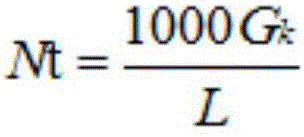

[0048] ② Weft yarn, the carbon fiber and copper fiber are twisted and plied as the weft yarn; the weft yarn is determined by the following formula

[0049] N t = 1000 G k L

[0050] Mass fraction of carbon fiber and copper fiber:

[0051]In the formula, Nt-represents the linear density of the yarn, tex; Gk-represents the weight of the yarn at a given moisture regain, g; L-represents the length of the yarn, m; the mixing ...

Embodiment 3

[0059] A carbon fiber / copper fiber carbon-based friction material with a shallow cross-bending structure. The preparation method of the friction material includes the following steps:

[0060] (1) Preparation of carbon fiber / copper fiber prefabricated body with shallow cross-bending structure:

[0061] ① Warp yarn, 10 strands of 1650dtex copper fibers are parallel twisted, and the twist is 10 twists / 10cm, as the warp yarn;

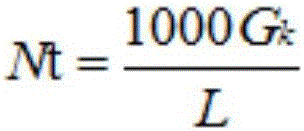

[0062] ② Weft yarn, the carbon fiber and copper fiber are twisted and plied as the weft yarn; the following formula is used for the weft yarn to determine the mass fraction of carbon fiber and copper fiber:

[0063] N t = 1000 G k L

[0064] In the formula, Nt-represents the linear density of the yarn, tex; Gk-represents the weight of the yarn at a given moisture regain, g; L-represents the length of the yarn, m; the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com