Manufacturing template for multichannel quartz crystal microbalance chip

A quartz crystal and multi-channel technology, applied in measuring devices, instruments, electric/magnetic thickness measurement, etc., can solve the problems of irregular concave hole size, unpromoted MQCM, high toxicity of HF, etc., achieve regular table shape and improve production Efficiency and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

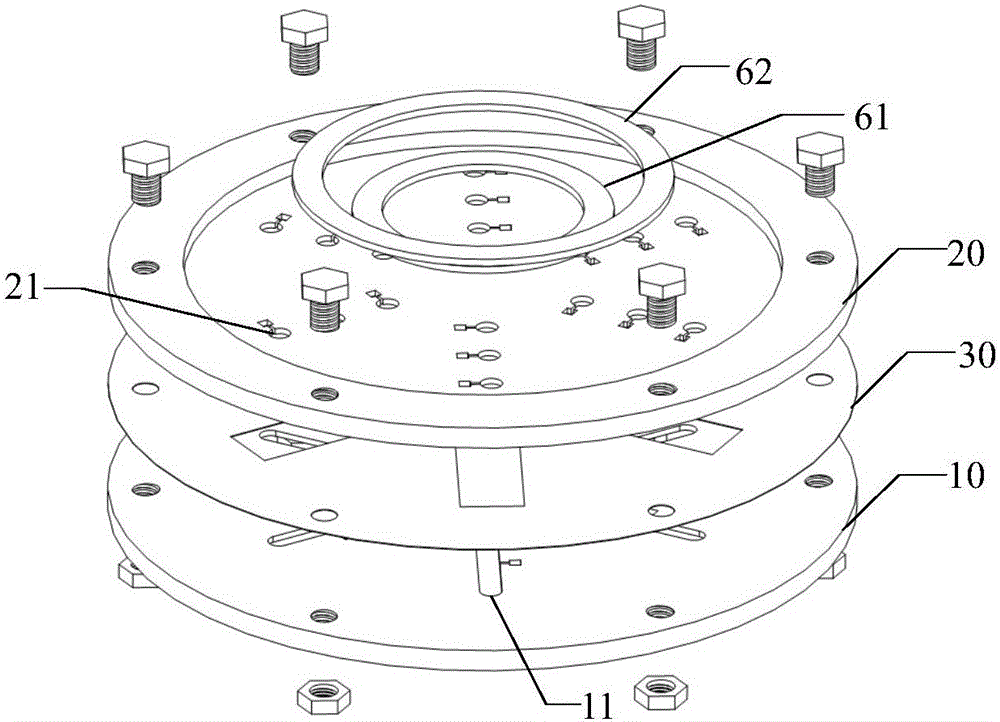

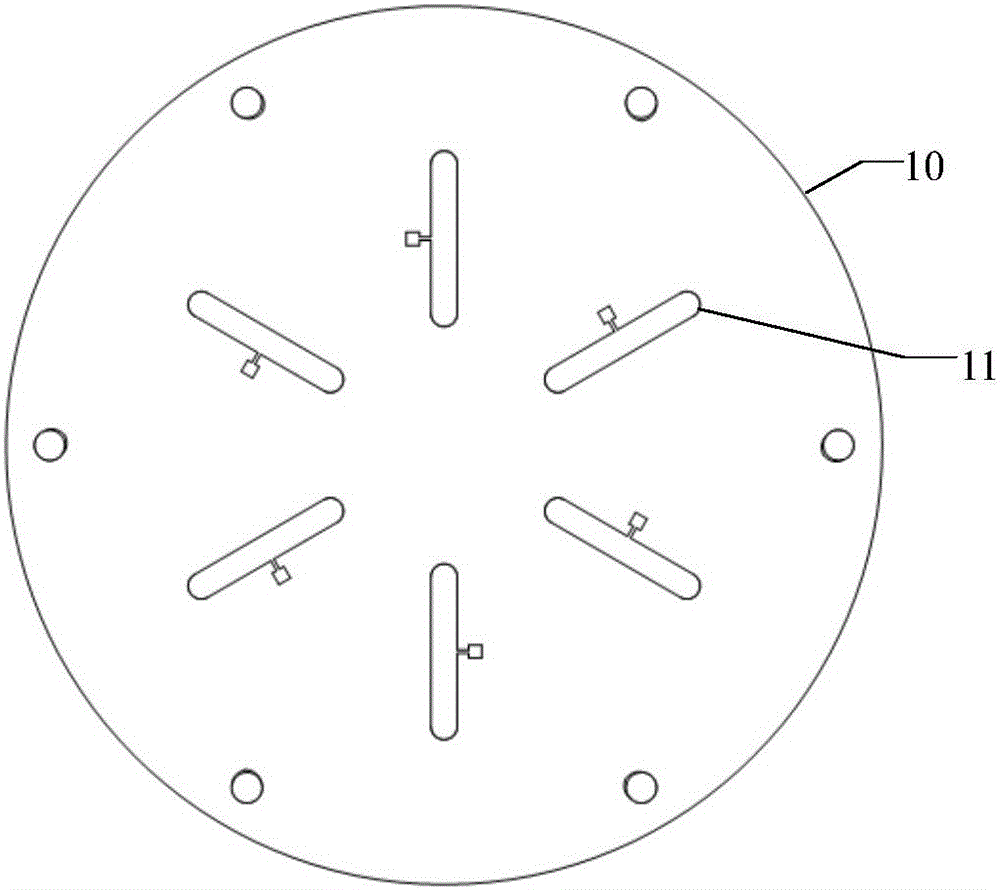

[0039] Figure 1-6 Shown, a kind of embodiment of the present invention is: a kind of manufacture template of multi-channel quartz crystal microbalance chip, comprises electrode processing part, and its structural feature is: described electrode processing part is formed by common electrode processing plate 10 that is positioned at the bottom It is composed of a functional electrode processing plate 20 detachably fixed on the upper part of the common electrode processing plate 10. There is at least one common electrode hole 11 for processing the common electrode on the common electrode processing plate 10. The functional electrode processing plate 20 is connected with At least two functional electrode holes 21 for processing functional electrodes are opened in the area corresponding to each common electrode hole 11; a chip fixing plate 30 is arranged between the common electrode processing plate 10 and the functional electrode processing plate 20, The chip fixing plate 30 is p...

Embodiment 2

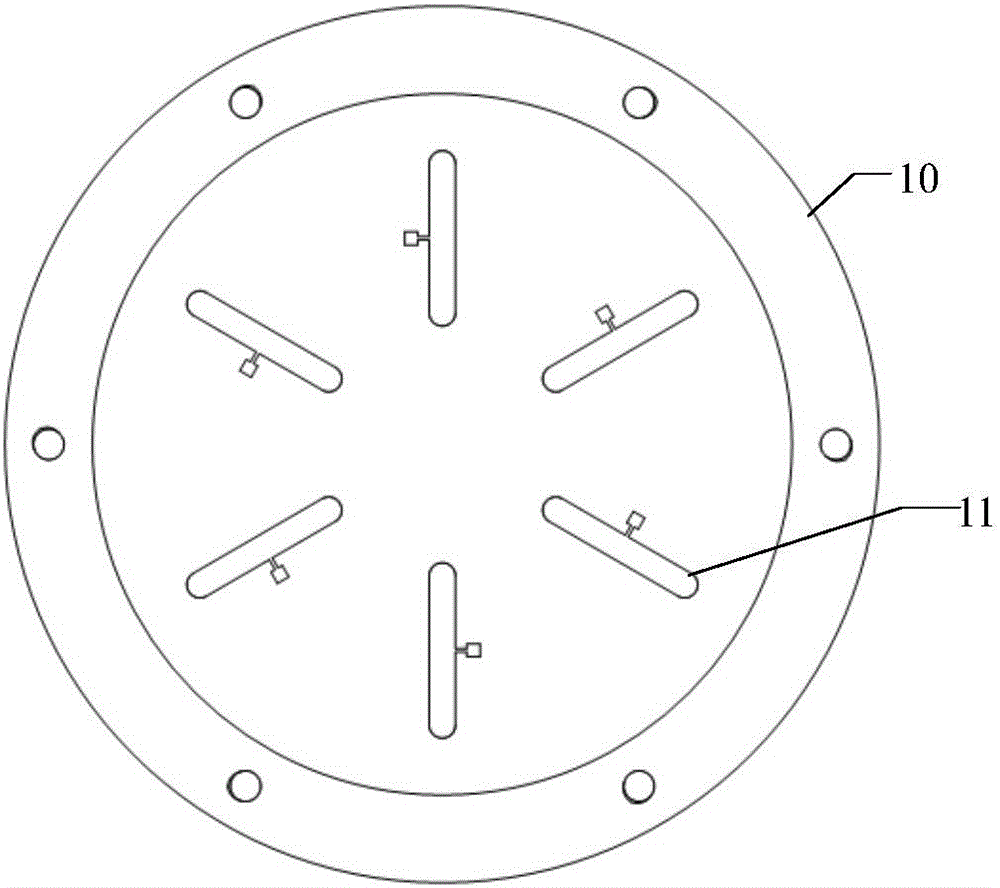

[0043] Figure 7-12 Shown, another kind of embodiment of the present invention is: a kind of manufacture template of multi-channel quartz crystal microbalance chip, comprises electrode processing part, and its structural feature is: described electrode processing part is formed by the common electrode processing plate that is positioned at the bottom 10 and a functional electrode processing plate 20 fixed on the top of the common electrode processing plate 10 in a detachable manner. There is at least one common electrode hole 11 for processing the common electrode on the common electrode processing plate 10. At least two functional electrode holes 21 for processing functional electrodes are opened in the area corresponding to each common electrode hole 11; a chip fixing plate 30 is arranged between the common electrode processing plate 10 and the functional electrode processing plate 20 , the chip fixing plate 30 is provided with a chip fixing through hole 31 for fixing the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com