Regeneration method of dehydrogenation catalyst for low-carbon alkane

A technology for dehydrogenation catalysts and low-carbon alkanes, applied in the direction of catalyst regeneration/reactivation, carbon compound catalysts, catalysts, etc., can solve the problems of many operation steps, danger, and irreversible deactivation of catalysts, and achieve small temperature changes and easy operation , Eliminate the effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1)PtSn / Al 2 o 3 After reacting at 540°C on the catalyst for 8 hours, switch to nitrogen, with a space velocity of 6000ml / g / h, and purging to cool down to 200°C;

[0024] (2) 10% H with a space velocity of 15000ml / g / h is introduced 2 / N 2 Purge for 0.5 hours, raise the temperature at 5°C / min to 450°C and keep it for 0.5 hours, then raise the temperature to 540°C at 5°C / min and keep it for 2 hours;

[0025] (3) After switching nitrogen purging, the reaction raw material gas was re-introduced to carry out the reaction again, and the above steps were repeated for a total of 4 regenerations.

Embodiment 2

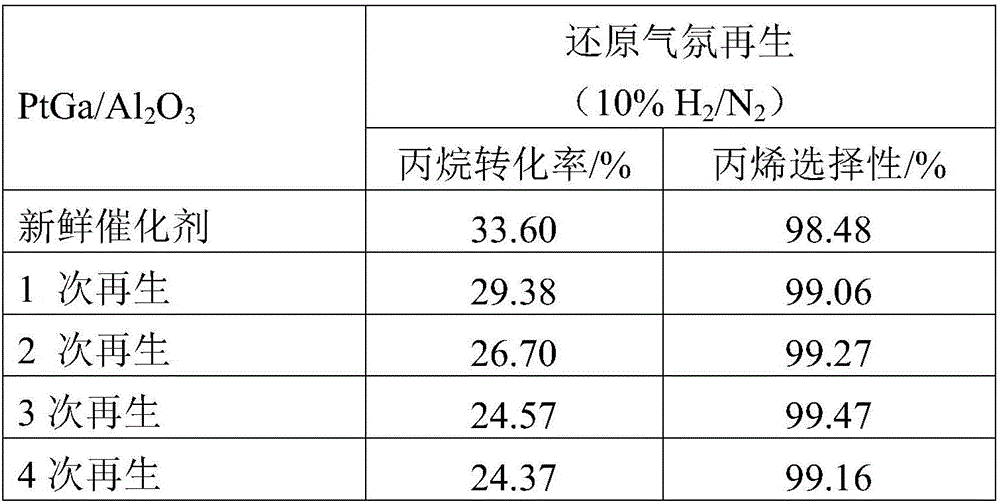

[0032] PtGa / Al 2 o 3 The catalyst is regenerated in a reducing atmosphere, the steps are the same as in Example 1, and the results are shown in Table 2. After 4 times of reductive regeneration, PtGa / Al 2 o 3 73% of the activity remained.

Embodiment 3

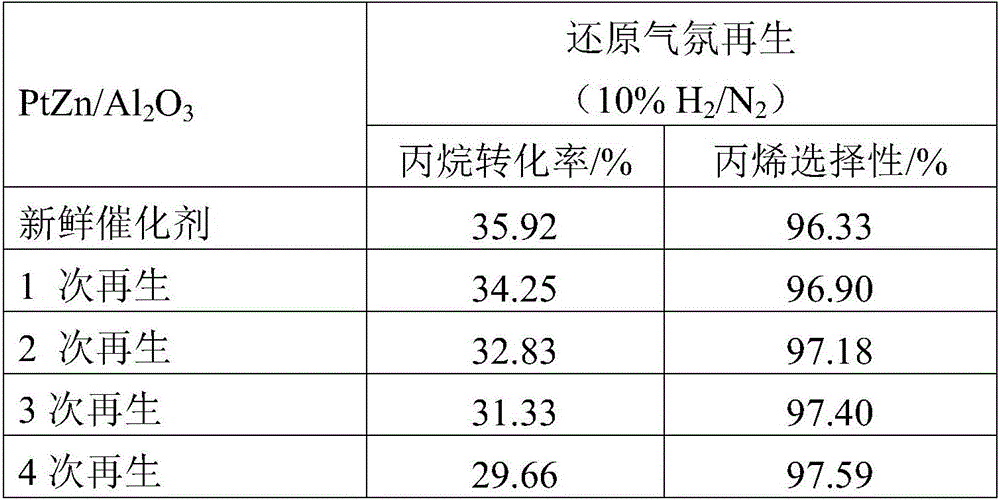

[0034] PtZn / Al 2 o 3 The catalyst is regenerated in a reducing atmosphere, the steps are the same as in Example 1, and the results are shown in Table 3. After 4 times of reductive regeneration, PtZn / Al 2 o 3 83% of the activity remained.

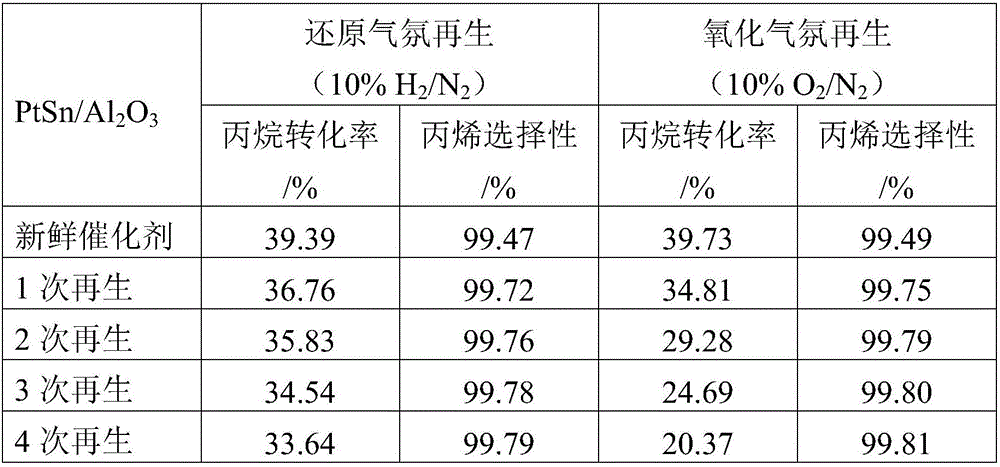

[0035] Table 1 PtSn / Al 2 o 3 Regeneration comparison between reducing atmosphere and oxidizing atmosphere on catalyst

[0036]

[0037] Table 2 PtGa / Al 2 o 3 Results of Reducing Atmosphere Regeneration on Catalyst

[0038]

[0039] Table 3 PtZn / Al 2 o 3 Results of Reducing Atmosphere Regeneration on Catalyst

[0040]

[0041] As can be seen from the data in the above tables, the low-carbon alkane dehydrogenation catalyst after applying the method of the present invention to regenerate has higher activity than the catalyst regenerated in oxidative atmosphere, and obviously the method of the present invention can more effectively regenerate low Catalysts for the dehydrogenation of alkanes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com