Production formula of cold-resistant HIPS particle

A production formula and cold-resistant technology, which is applied in the field of production formula of HIPS particles, can solve the problems of poor cold resistance, product aging, and difficulty in demoulding, and achieve high cold resistance, not easy to age, and easy to demould.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The production formula of cold-resistant HIPS particles, the production formula includes the following components in weight percentage, HIPS resin powder 85-95%, cold-resistant agent 2-6.5%, UV powder 0.5-1%, iron oxide black powder 0.5-1% and silicon steel powder 2-8%.

[0015] Among them, bis(2-ethylhexyl) adipate is selected as the cold-resistant agent, and the main component of the black iron oxide powder is ferric iron tetroxide. In this embodiment, each component in the production formula is mixed evenly and put into a granulator for processing to obtain cold-resistant HIPS particles. The granulation process by the granulator is a prior art, and will not be repeated here. The cold-resistant HIPS particles obtained in this example have extremely high cold-resistant performance, and the products injection-molded using cold-resistant HIPS particles are kept in an environment of minus 30 degrees Celsius for a long time. Demoulding helps to improve production efficien...

Embodiment 2

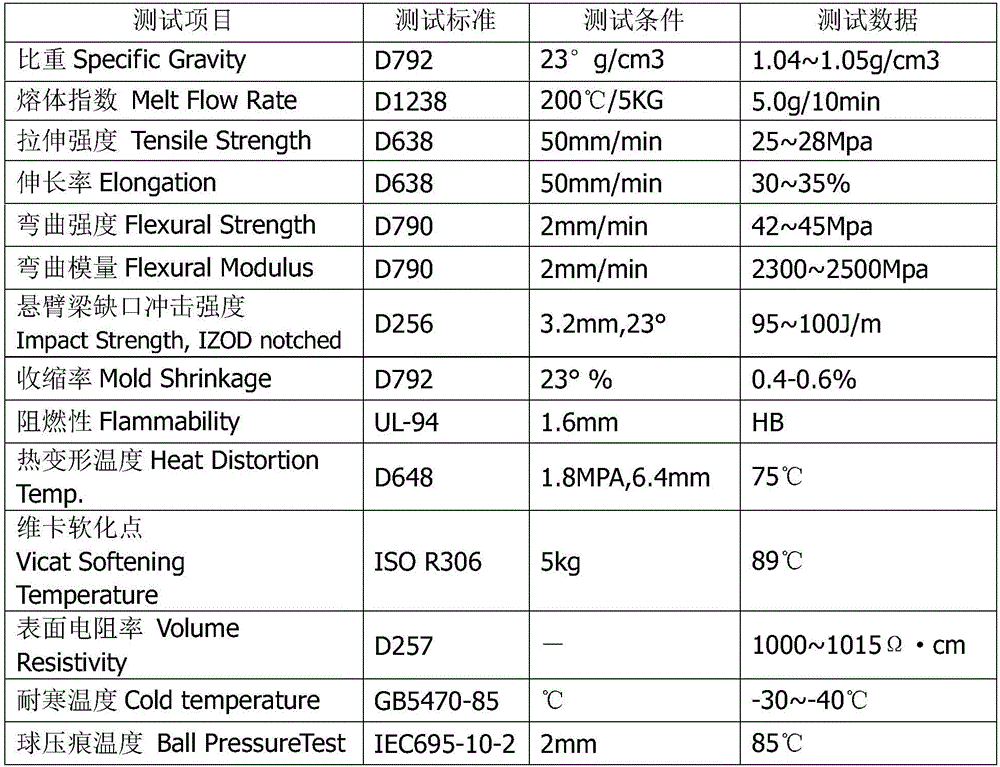

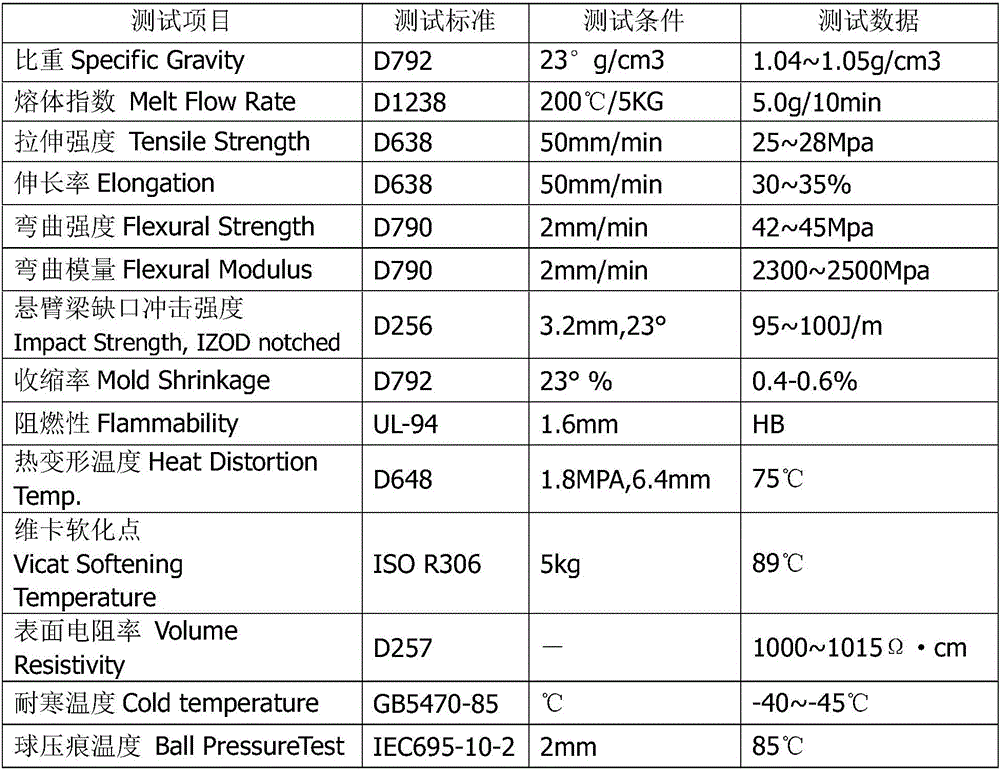

[0019] The production formula of cold-resistant HIPS particles, the production formula includes the following components in weight percentage, HIPS resin powder 85-89%, cold-resistant agent 4-6.5%, UV powder 0.5-1%, iron oxide black powder 0.5-1% and silicon steel powder 5-8%. This example is based on Example 1 to further narrow the range of the weight ratio of each component, according to the formulation of this implementation can obtain cold-resistant HIPS particles with the properties shown in Table 1.

Embodiment 3

[0021] The production formula of cold-resistant HIPS particles is composed of the following components in weight percentage, HIPS resin powder 85%, cold-resistant agent 6.5%, UV powder 1%, iron oxide black powder 1% and silicon steel powder 6.5%. This example is one of the specific formulations of the present invention, and cold-resistant HIPS particles with better performance as shown in Table 1 can be obtained according to the formulation of this implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com