Unicellular microorganism fermentation system and method

A technology of microbial fermentation and fermentation method, which is applied in the field of biological fermentation equipment, can solve the problems of long time consumption, high cost, difficult pH control, etc., and achieve the effect of saving time and cost, avoiding waste, and easier control of pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

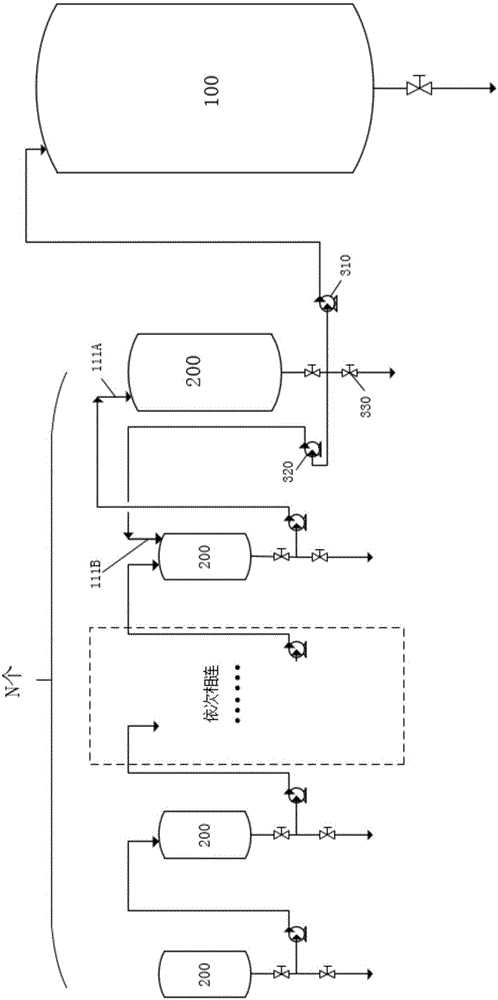

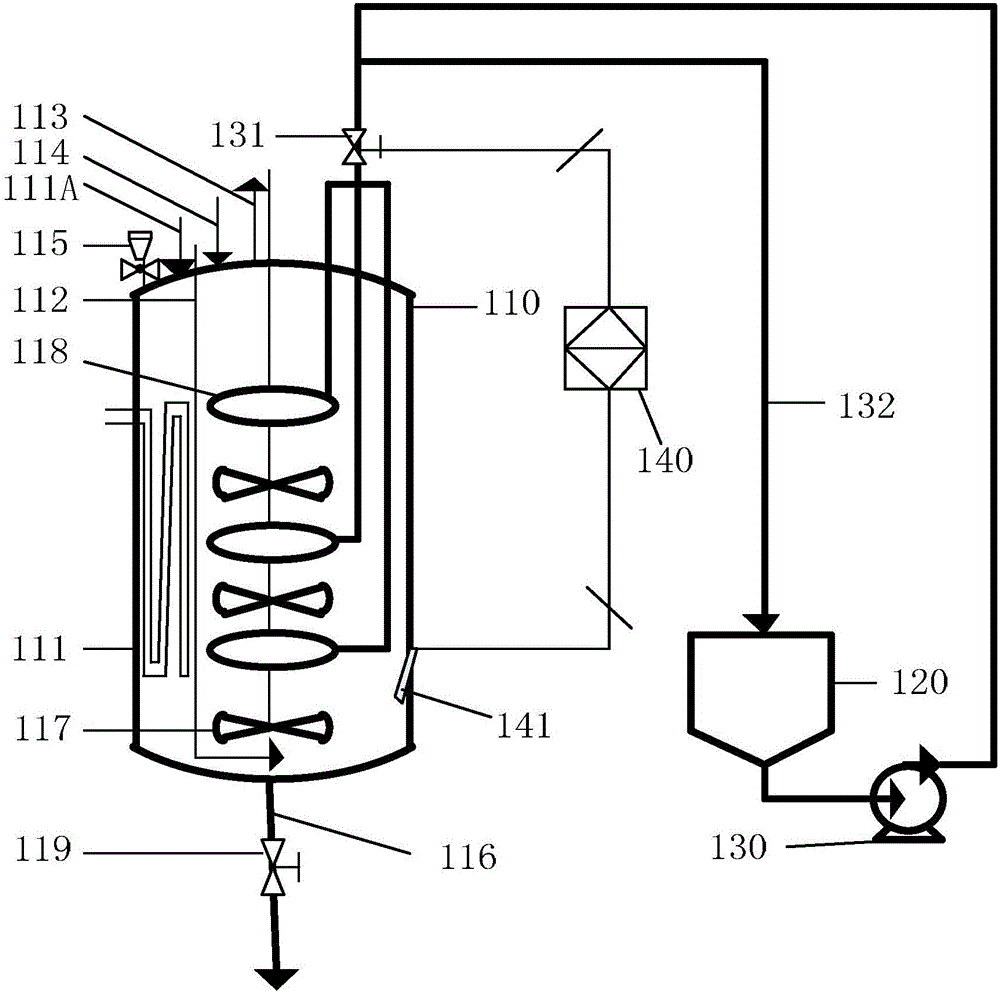

[0038] Embodiment 1, a single-cell microbial fermentation system, comprising a fermenter device 100 and a four-stage seed tank device 200, the fermenter device 100 and the four-stage seed tank device 200, each with one neutralizer storage tank;

[0039] The culture tank of the fermenter device has a diameter of 4.5m and a volume of 200m 3 , the inner wall of the tank body 111 is evenly distributed with temperature-controlled tubes, which are used to feed hot or cold media to heat up or cool down the tank body, and the respirator 115 is a 0.2 μm microporous filter; the inside of the tank body 111 There are 4 agitators and 4 neutralizer distributors respectively, the diameter of the closed circle constituting the neutralizer distributor is 1.125m, which is 1 / 4 of the diameter of the corresponding tank, and the inner diameter of the stainless steel pipe is 30cm;

[0040] The culture tank of the first-stage seed tank device has a volume of 30L and a diameter of 0.3m. The side wall...

Embodiment 2

[0044] Embodiment 2, a single-cell microbial fermentation system, comprising a fermenter device 100 and a three-stage seed tank device 200, each of the fermenter device 100 and the three-stage seed tank device 200 has two neutralizer storage tanks,

[0045] The volume of the culture tank of the fermenter device is 300m 3 , a diameter of 5.8m, the inner wall of the tank body 111 is evenly distributed with temperature-controlled tubes, which are used to feed hot or cold media to heat up or cool down the tank body, and the respirator 115 is a microporous filter of 0.2 μm; There are 4 agitators and neutralizer distributors in the tank 111 respectively. The diameter of the closed circle constituting the neutralizer distributor is 4.35m, which is 3 / 4 of the corresponding tank diameter. The inner diameter of the stainless steel pipe is 30cm;

[0046] The culture tank of the first-stage seed tank device has a volume of 8L and a diameter of 0.2m. The side wall of the tank has a surrou...

Embodiment 3

[0049] Embodiment 3, utilize the system of embodiment 1, adopt the fermentation method that lactic acid bacteria carries out lactic acid fermentation production, comprise the following steps:

[0050] A. Pre-installation steps: before the system starts, prepare 50% calcium hydroxide emulsion in the neutralizer storage tanks of the fermenter device 100 and the seed tank devices 200 at all levels for subsequent use, and sterilize each neutralizer feeding pipe; Fill fresh culture medium in the culture tank tank body of the first-stage seed tank device 200 and sterilize it; carry out step B;

[0051] B. Seed expansion step: adopt high-temperature-resistant anaerobic lactic acid bacteria (Lactobacillus casei B9232) to carry out 1.6L seed culture in the shake flask, reach the logarithmic phase in about 15 hours, complete the seed culture, and transplant the seeds to the first In the cultivation tank tank of the first-grade seed tank device;

[0052] Turn on the circulation pump cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com