Heat-dissipation LED lamp

A technology for LED lamps and LED light sources, which is applied to lampshades, lighting and heating equipment, cooling/heating devices for lighting devices, etc., can solve the problems of increased cost, increased weight of heat-dissipating LED lamps, and insufficient heat-taking capacity, and achieves the speed of heat dissipation. The effect of fast, low freezing point and strong heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

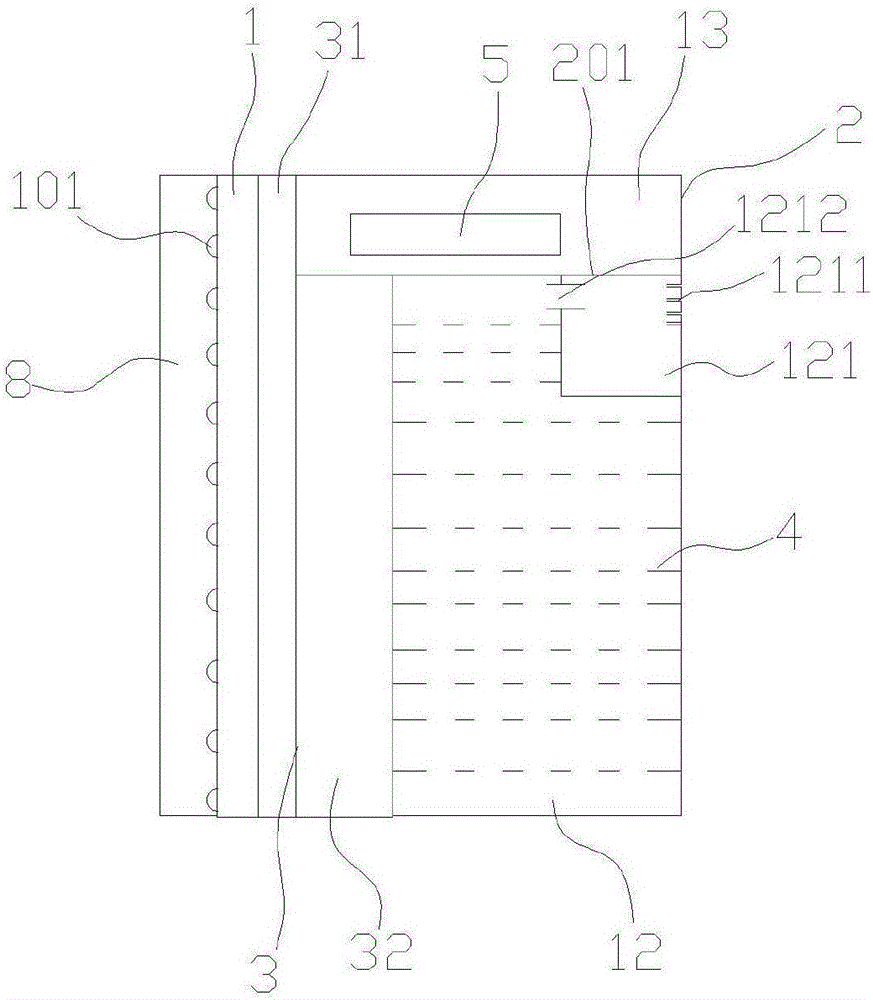

[0032] figure 1 and figure 2 A heat dissipation LED lamp provided according to the first embodiment of the present invention is schematically shown.

[0033] Such as figure 1 As shown, a heat dissipation LED lamp provided by this embodiment of the present invention includes an LED light source substrate 1 and an outer shell 2, and an LED controller 5 is connected to the LED light source substrate 1, and the LED controller 5 controls a LED light source provided by the present invention. A heat dissipation LED light is turned on and off.

[0034] Such as figure 1 As shown, the outer casing 2 is a hollow cuboid, and the outer casing 2 is separated by a partition 201 to form two upper and lower cavities, wherein the upper cavity is the control cavity 13, the LED controller 5 is fixed in the control cavity 13, and the lower cavity For the cavity 12 , the partition 201 seals and isolates the control cavity 13 from the cavity 12 , preferably, the cavity 12 is larger than the con...

Embodiment 2

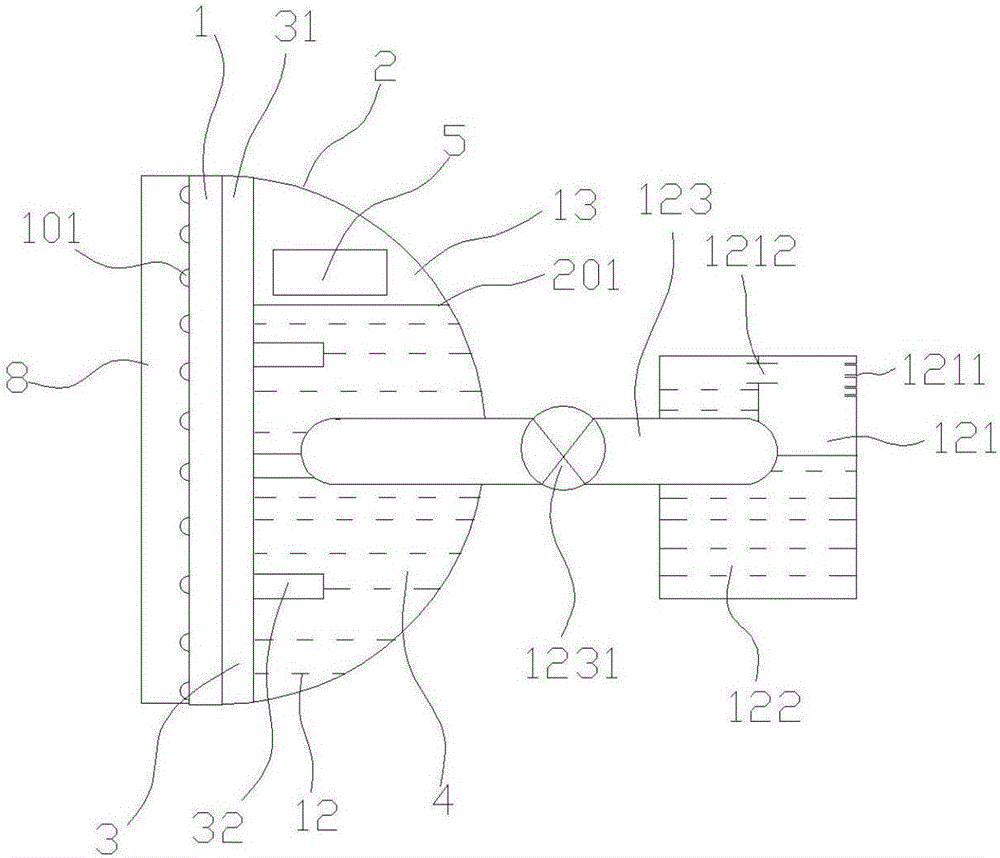

[0041] image 3 and Figure 4 A heat dissipation LED lamp provided according to the second embodiment of the present invention is schematically shown.

[0042] Such as image 3 As shown, a heat dissipation LED lamp provided by this embodiment of the present invention includes an LED light source substrate 1 and an outer shell 2, and an LED controller 5 is connected to the LED light source substrate 1, and the LED controller 5 controls a LED light source provided by the present invention. A heat dissipation LED light is turned on and off. Such as image 3 As shown, the LED controller 5 is connected to one end of the LED light source substrate 1,

[0043] Such as image 3 As shown, the outer casing 2 is a hollow hemisphere, and the outer casing 2 is separated by a partition 201 to form two upper and lower cavities, wherein the upper cavity is the control cavity 13, the LED controller 5 is fixed in the control cavity 13, and the lower cavity is The cavity is the cavity 12 ,...

Embodiment 3

[0051] A heat dissipation LED lamp provided in Embodiment 3 of the present invention has the same structure as the substrate of a heat dissipation LED lamp provided in Embodiment 2, the difference is that, as Figure 4 As shown, in this embodiment of the invention, two heat dissipation LED lamps are connected to an external liquid storage tank 122, such as Figure 4 As shown, the outer liquid storage tank 122 communicates with the cavities 12 of the two heat-dissipating LED lamps through four liquid passages 123 respectively.

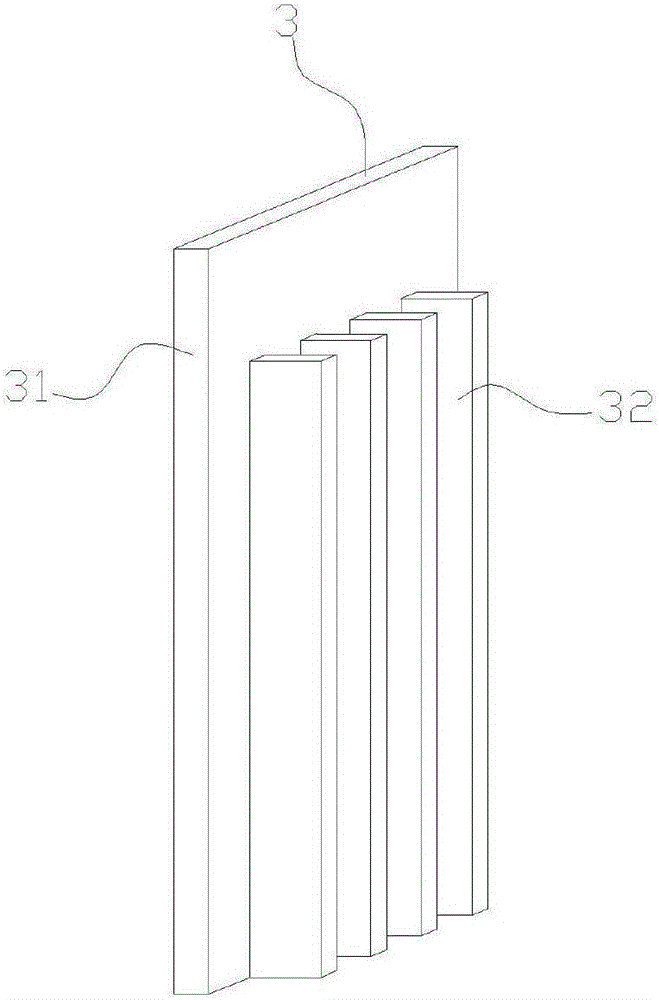

[0052] In addition, as preferred, such as Figure 6 As shown, in this embodiment of the present invention, the graphite heat-taking plate 3 includes a heat-taking plate substrate 31 and several graphite fins 32 connected with the heat-taking plate substrate 31. In this embodiment of the present invention, 12 A graphite fin 32 is vertically connected with the heating plate base plate 31, and the graphite fin 32 is in a wave shape, and one end of the wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com