Method for processing novel composite silicone rubber solid insulated bus

A composite silicone rubber and solid insulation technology, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, electrical components, etc., can solve the problem of dust, conductive particles, moisture entering, affecting the insulation performance of the busbar, affecting product reliability and safety sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

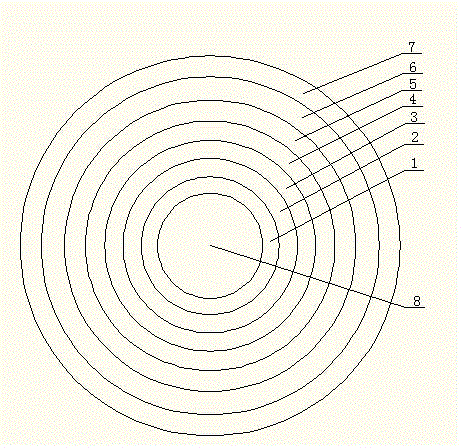

[0020] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0021] Such as figure 1 As shown, the novel composite silicone rubber solid insulated bus bar of the present invention comprises tubular conductive tube 1, coupling agent layer 2, main insulating layer 3, semiconducting layer 4, insulating shielding layer 5, grounding layer 6 and The heat-shrinkable sleeve protects the tube layer 7, the conductive tube 1 is made of T2Y copper tube, the insulation shielding layer 4 is made of T2R copper foil, and the ground layer 5 is made of T2R copper foil and grounding wire.

[0022] In order to make the composite silicone rubber solid insulated bus bar of the present invention have good heat dissipation an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com