Novel solid-state capacitor and production method of the same

A production method and capacitor technology, applied in solid electrolytic capacitors, capacitor parts, electrolytic capacitor manufacturing, etc., can solve the problems of high resistance to ripple current, low capacitor ESR, and low withstand voltage, and achieve high resistance to ripple current. The effect of high value, low leakage current and high withstand voltage value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

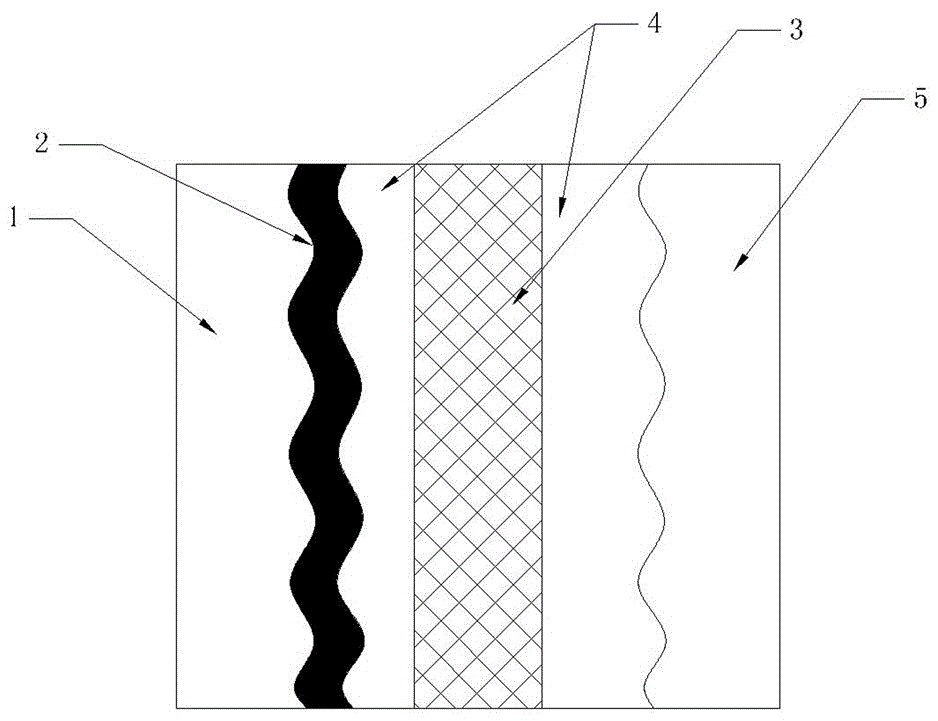

[0028] Such as figure 1 A new type of solid capacitor is shown, including a core package sealed in the shell. The core package is wound by anode foil 1, non-carbonized electrolytic paper 3 and cathode foil 5. PEDT is attached to the electrolytic paper, and the electrolytic paper and the anode The foil and the space between the electrolytic paper and the cathode foil are filled with PEDT:PSS4.

[0029] The production method of the new solid capacitor in this embodiment includes the following steps: 1) impregnating the cut electrolytic paper in the conductive polymer monomer with a concentration of 1-40wt% (40wt% in this embodiment);

[0030] 2) Dry the electrolytic paper impregnated with conductive polymer;

[0031] 3) Immerse the dried electrolytic paper into an oxidant solution with a concentration of 10-70wt% (70wt% in this embodiment);

[0032] 4) Polymerize the electrolytic paper in step 3) in an environment with a temperature ranging from room temperature to 200°C for 1...

Embodiment 2

[0040] The production method of the novel solid capacitor of this embodiment includes the following steps, 1) immersing the cut electrolytic paper into a mixed solution of conductive polymer monomer and oxidant for 0.5-60 min; wherein the concentration of the conductive polymer monomer is 1 ~40wt%, oxidant concentration 10~70wt%;

[0041] 2) Polymerize the impregnated electrolytic paper in an environment with a temperature ranging from room temperature to 170°C for 1 to 48 hours, so that PEDT is polymerized on the electrolytic paper;

[0042] 3) The electrolytic paper polymerized with PEDT is wound together with the anode foil and the cathode foil into a core pack, and the core pack is immersed in the dispersion liquid of PEDT:PSS, so that PEDT:PSS is filled into the gap between the anode foil and the cathode foil void.

[0043] Other parts of this embodiment are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com