Multi-frequency multiplication double stop-band filter

A filter and double-stop band technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of single stop-band filter, lack of two stop-band filter characteristics, and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

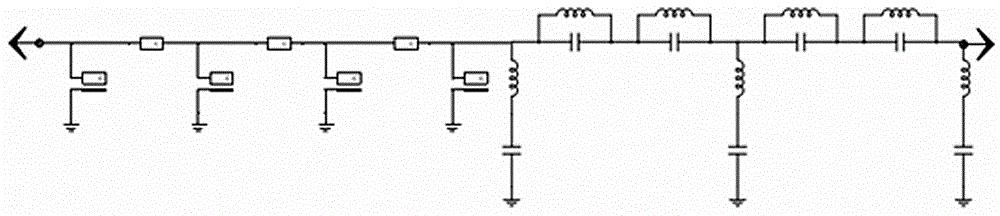

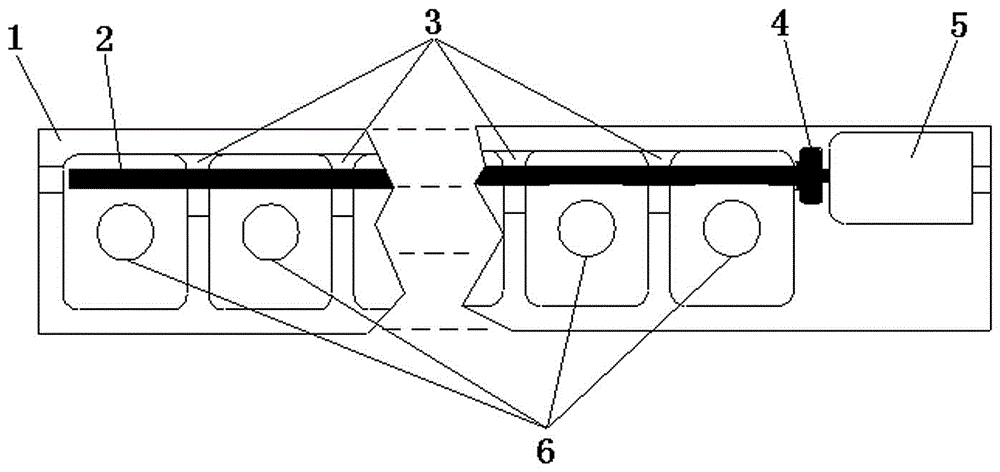

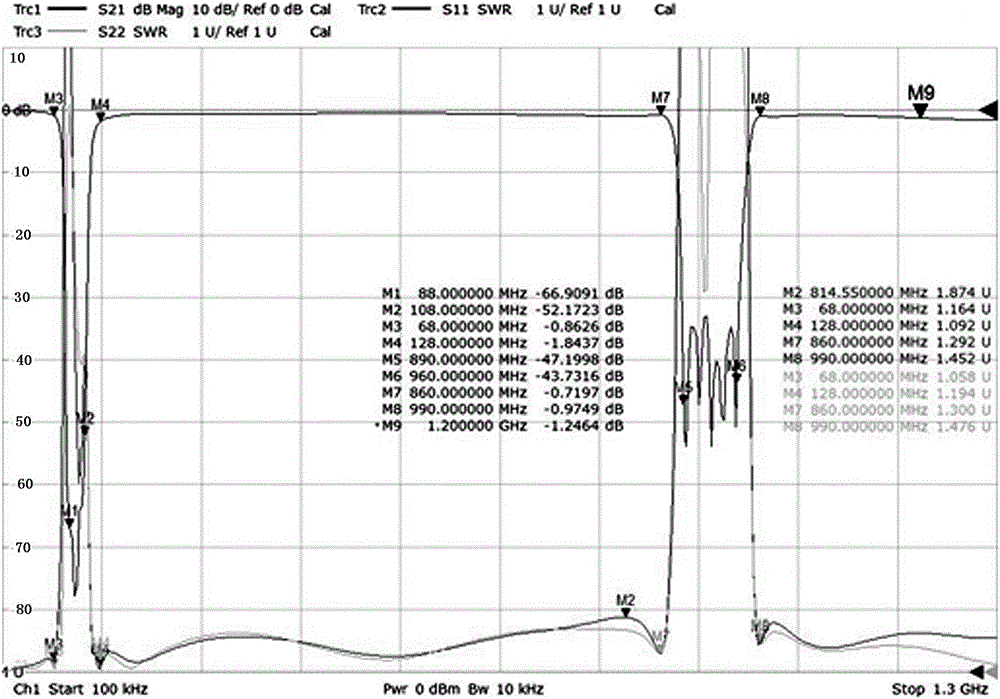

[0028] There are coupling rod 2, polytetrafluoroethylene medium 3, microstrip line 4, LC filter 5, and resonator 6 in the cavity 1. The coupling rod 2 is connected with four parallel resonators 6 to form the first stop band filter. The resonator 6 is a normalized frequency generator, which plays the role of generating frequency signals in the cavity 1, and the coupling rod 2 is three normalized couplers in series, and the coupling rod passes through the microstrip line 4 and the second stopband filter The second stop band filter is composed of three series LC resonators and four parallel LC resonators 5, the coupling rod 2 outputs the frequency signal to the microstrip line 4, and the polytetrafluoroethylene medium 3 fixes the coupling rod, The stopband bandwidth is realized by adjusting the distance between the coupling rod 2 and the resonator 6, the frequency can be adjusted by using the resonator 6, and finally the output of the first stopband filter is transmitted to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com