Preparing method for compressible saccharose

A technology of compressibility and sucrose, which is applied in the field of preparation of compressible sucrose, can solve the problems of complex process and low yield, and achieve the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

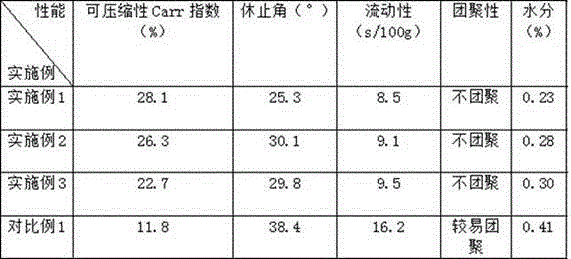

Examples

Embodiment 1

[0028] Crush and sieve sucrose to obtain 100-mesh sucrose powder; sieve talcum powder to obtain 100-mesh sucrose powder; weigh 20kg sucrose powder and 0.04kg talcum powder; weigh 1kg maltodextrin, add 6kg water, stir evenly to dissolve ; Turn on the fluidized bed system, feed gas into the fluidized bed from the air inlet, and heat the system to the predetermined temperature: the upper temperature control point is set at 200°C, and the lower temperature control point is set at 75°C; The sucrose powder is added into the fluidized bed at one time and the bed is sealed; adjust the air flow of the air inlet to 0.3Mpa to fluidize the sucrose; after the system temperature is stabilized at the set value, start the spray device to spray into particles The air pressure of the nozzle is 0.5MPa; after spraying a certain amount of solution, continue to heat and maintain fluidization for several 10 minutes, so that the solute sprayed into the droplets in the later stage is completely decompo...

Embodiment 2

[0030] Crush and sieve sucrose to obtain 80-mesh sucrose powder; sieve talc powder to obtain 80-mesh talc powder; weigh 20kg sucrose powder and 0.06kg talcum powder; weigh 0.6kg sorbitol, add 3kg water, stir evenly to dissolve ; Turn on the fluidized bed system, feed gas into the fluidized bed from the air inlet, and heat the system to the predetermined temperature: the upper temperature control point is set at 180°C, and the lower temperature control point is set at 65°C; The sucrose powder and talcum powder are added into the fluidized bed at one time and the bed is sealed; the air flow at the air inlet is adjusted to 0.25Mpa to fluidize the sucrose; after the system temperature is stabilized at the set value, the spray device is started to carry out Spray into particles; the air pressure of the nozzle is 0.3MPa; after spraying a certain amount of solution, continue to heat and maintain fluidization for 8 minutes, so that the solute sprayed into the droplets in the later stag...

Embodiment 3

[0032] Crush and sieve the sucrose to obtain 100-mesh sucrose powder; sieve talc powder to obtain 100-mesh sucrose powder; weigh 20 kg of sucrose powder and 0.04 kg of talc powder; weigh 0.5 kg of starch, add 6 kg of water, stir evenly, and dissolve it; Turn on the fluidized bed system, feed gas into the fluidized bed from the air inlet, and heat the system to the predetermined temperature: the upper temperature control point is set at 200°C, and the lower temperature control point is set at 75°C; the weighed Add sucrose powder to the fluidized bed at one time and seal the bed; adjust the air flow at the air inlet to 0.3Mpa to fluidize the sucrose; after the system temperature is stabilized at the set value, start the spray device to spray into particles; The air pressure of the nozzle is 0.5MPa; after spraying a certain amount of solution, continue to heat and maintain fluidization for 10 minutes, so that the solute sprayed into the droplets in the later stage is completely de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com