Bottom polishing machine for revolving body workpiece

A polishing machine and body workpiece technology, which is applied to surface polishing machine tools, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of high labor cost and low efficiency, achieve low labor cost, reduce environmental pollution, The effect of high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

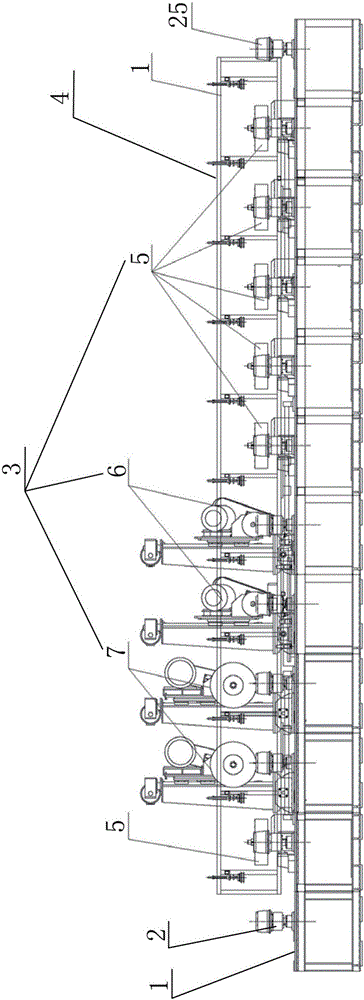

[0024] like Figure 1 to Figure 11 A polishing production line for rotary workpieces shown includes a worktable 1 arranged along the assembly line, on which a plurality of positioning mechanisms 2 for fixing rotary workpieces 25 are evenly spaced. One side of the workbench 1 is provided with a polishing mechanism 3 for polishing the rotary workpiece 25, and the other side of the workbench 1 is provided with a displacement mechanism 4 for shifting the rotary workpiece 25. As the polishing progresses, the shifting mechanism 4 sequentially shifts the rotary workpiece 25 from the positioning mechanism 2 at the beginning of the assembly line to the positioning mechanism 2 at the next stage until the end of the assembly line.

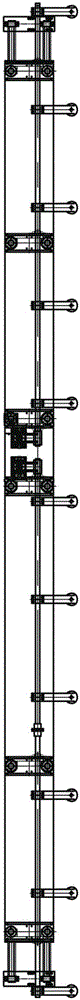

[0025] The positioning mechanism 2 includes a positioning head 16 , a rotating connector 17 , a rotating main shaft 18 and a rotating motor 19 . The upper end of the rotating connector 17 is connected with the positioning head 16, and the lower end of the ro...

Embodiment 2

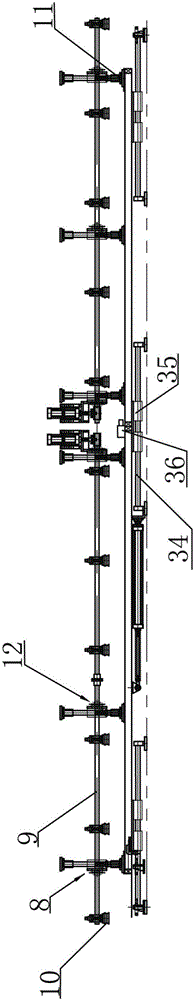

[0034] The difference between this embodiment and Embodiment 1 is that: the lifting cylinder 11 for controlling the lifting of the pneumatic suction cup installation shaft 9 is also arranged in the cutting frame 8 , and the pneumatic suction cup 10 is arranged directly above the positioning mechanism 2 .

Embodiment 3

[0036] The difference between the present embodiment and the second embodiment is that no pushing mechanism 12 is provided in the cutting frame 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com