Oil absorption ship

An oil suction vessel and oil suction pipe technology are applied in the field of oil slick recovery at sea, which can solve the problems of adverse impact on the ecological environment, unsuitable operation, cumbersome and other problems, and achieve the effect of convenient and efficient treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

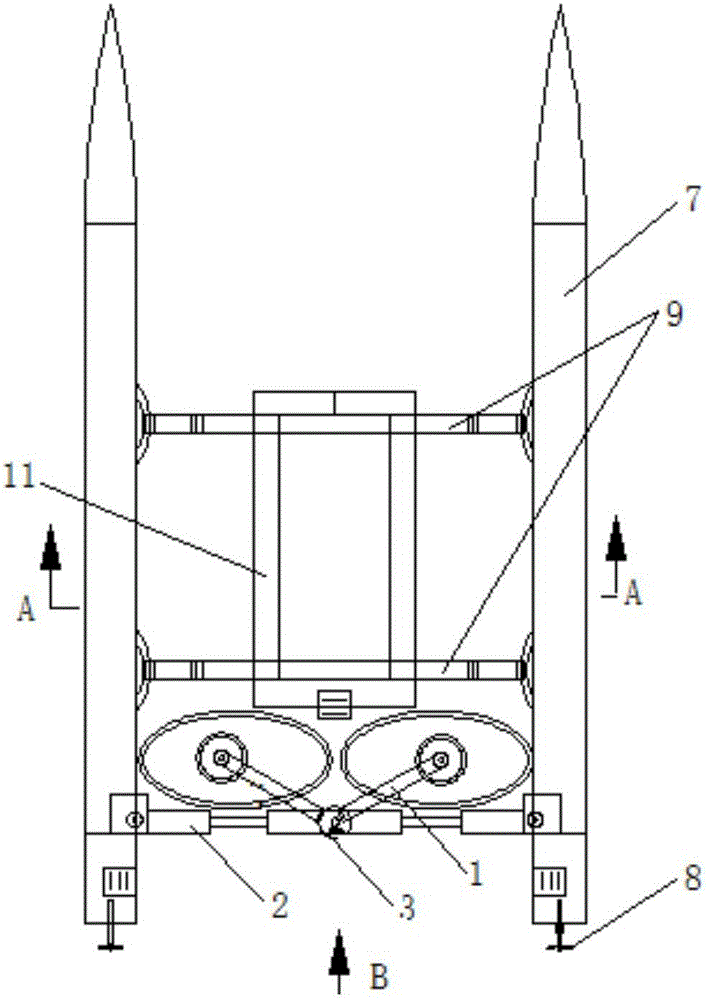

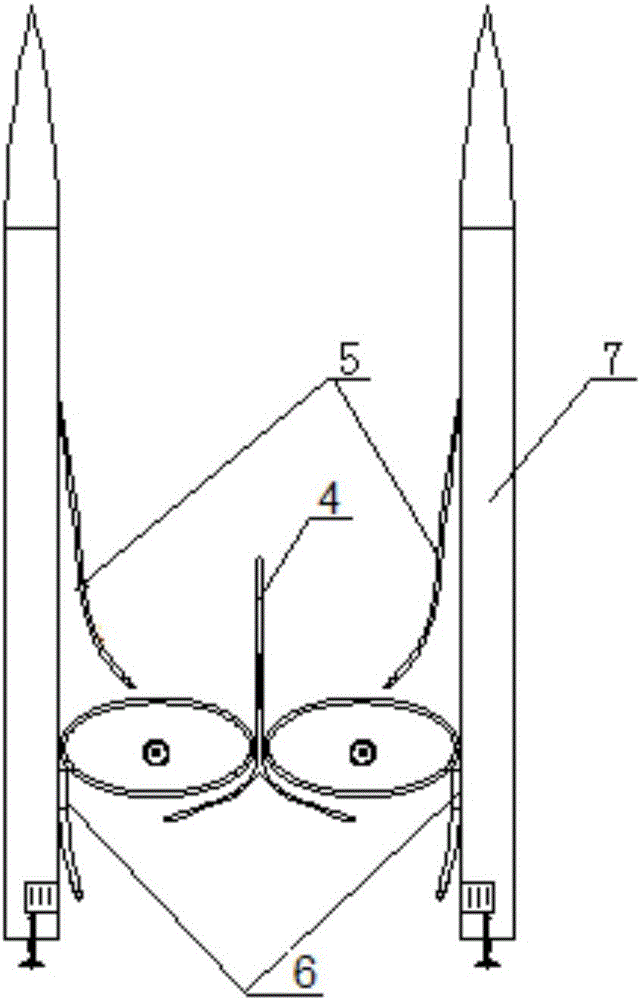

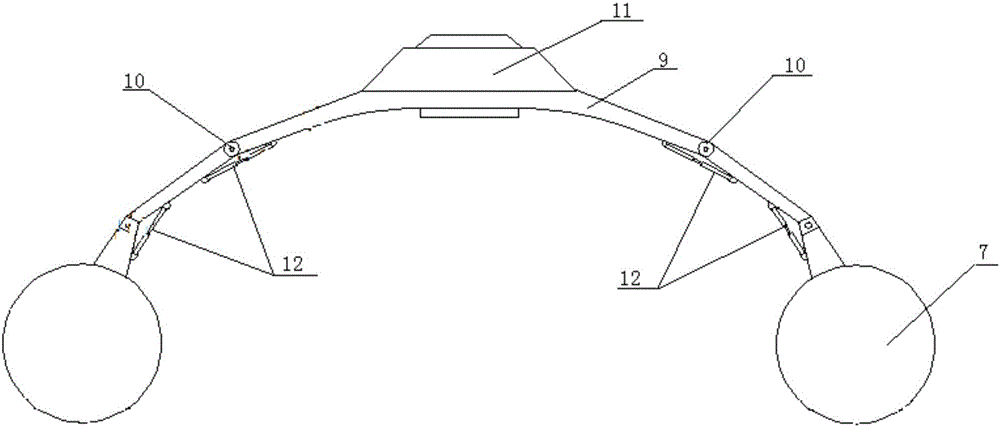

[0028] refer to Figure 1 to Figure 5 As shown, the oil suction ship in an embodiment provided by the present invention includes a hull, and an oil suction device 16 is provided on the hull. The oil suction device 16 includes an airtight barrel 18, an exhaust mechanism, an oil gathering mechanism and an oil suction mechanism, and the airtight barrel 18 is suspended upside down. When cleaning the oil slick on the water surface, the airtight barrel 18 is buckled upside down on the water surface. There is a certain gap between the mouth of the lower end of the airtight barrel 18 and the water surface. The exhaust mechanism is arranged on the top of the airtight barrel 18. At the lower end of the bung mouth, the oil suction mechanism includes an oil suction pipe 30, the bottom of the oil suction pipe 30 is arranged at the lower end of the bung mouth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com