Reclaimed water deep denitrification and dephosphorization method based on low C/N ratio

A technology for deep denitrification and water regeneration, applied in the field of environmental engineering, can solve the problems of limited carbon content in corn cob, inability to ensure denitrification and denitrification effect, and difficulty in achieving phosphorus removal, etc., and achieves the /N ratio of tail water deep denitrification synchronization. Improved effect of phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

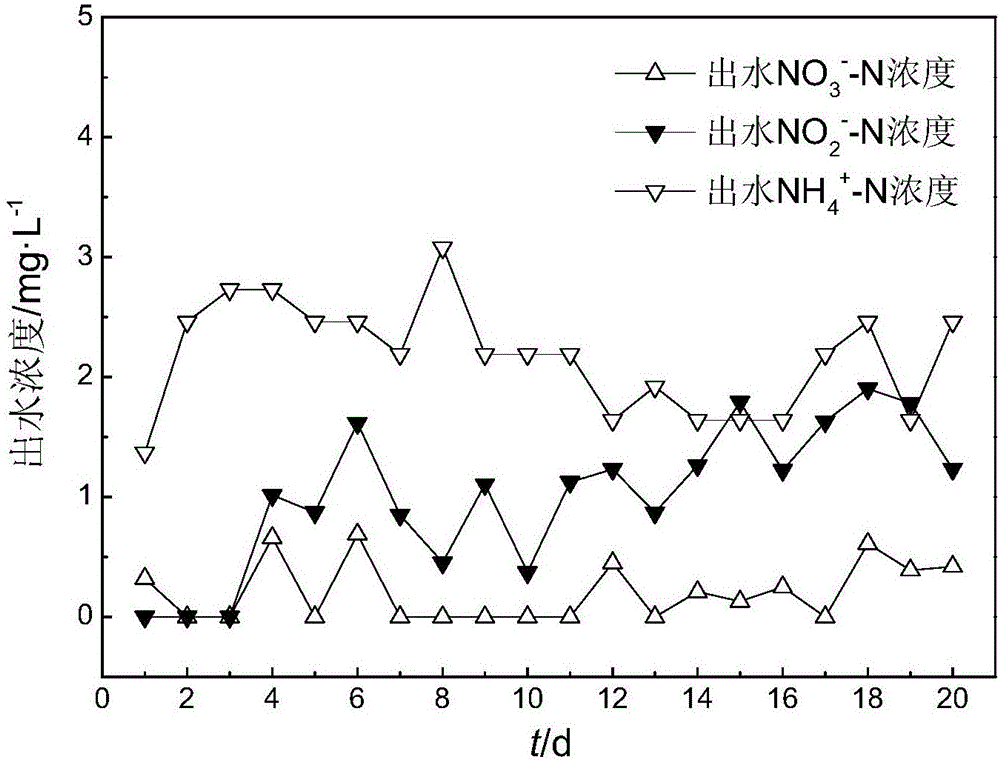

[0026] Test water Add a certain amount of KNO to tap water 3 and KH 2 PO 4 . Control the concentration of TN and TP as follows: ρ(TN)=ρ(NO 3 -N)=35mg.L -1 , ρ(H 2 PO 4 -P)=1.5mg.L -1 . At the same time with 1mol L -1 of hydrochloric acid and 1mol·L -1 Sodium hydroxide solution is used to adjust the pH value of the distribution water to maintain it at 6.8-7.2.

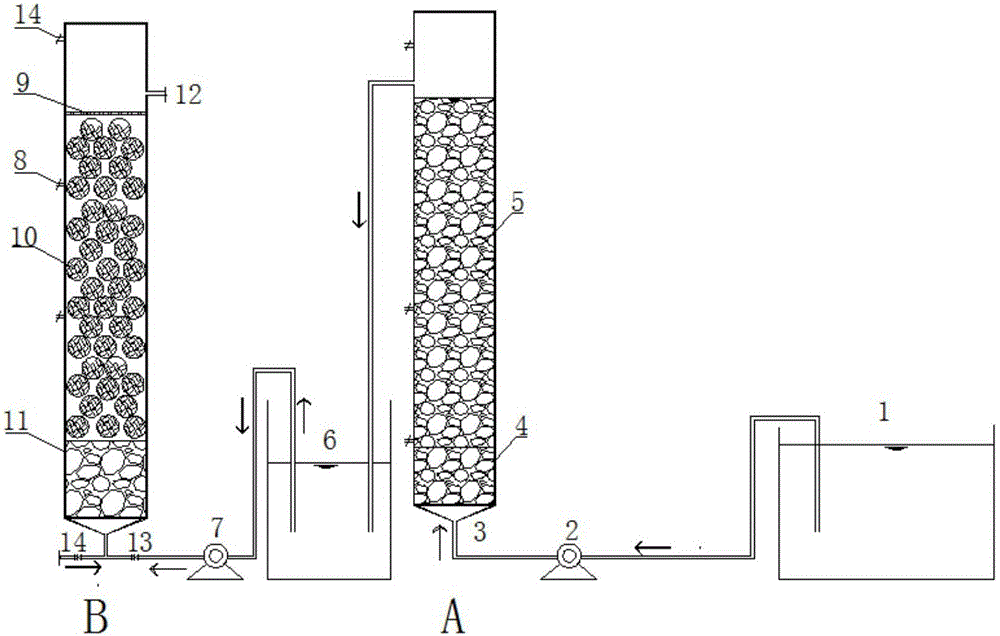

[0027] The reactor is attached figure 1 shown. Among them, the corncob is soaked in NaOH solution with a mass fraction of 1.5% for 10 hours, cut into small rectangles with a length of 2 to 3 cm and a width of 1 to 2 cm; the particle diameter of the sponge iron is 5 to 8 mm, and the particle diameter of the sulfur is 2 to 2 cm. 3mm. The inoculum sludge came from the return sludge of a sewage treatment plant in Beijing.

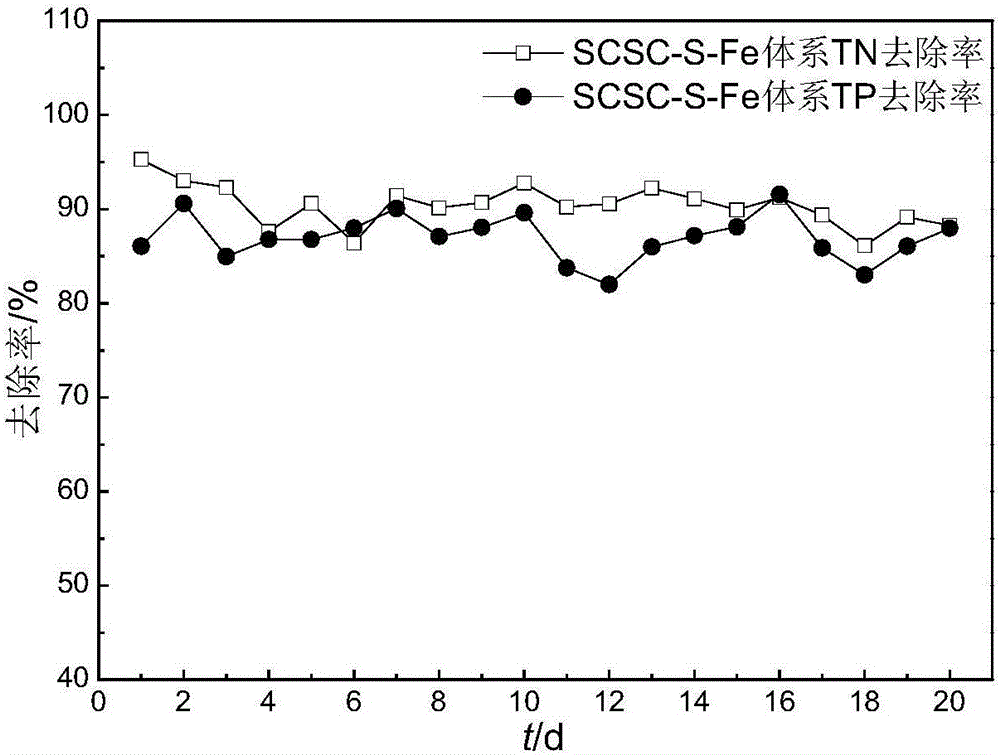

[0028] In the above implementation mode, the SCSC-S-Fe process is applied to the deep nitrogen and phosphorus removal process of the tail water of the urban sewage treatment plant to enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com