Multipurpose spray glue and preparation method thereof

A multi-purpose, glue-spraying technology, applied in adhesives, adhesive additives, non-polymer organic compound adhesives, etc., can solve problems such as low adhesion, strong penetration, and easy corrosion, and achieve strong adhesion , the effect of low penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

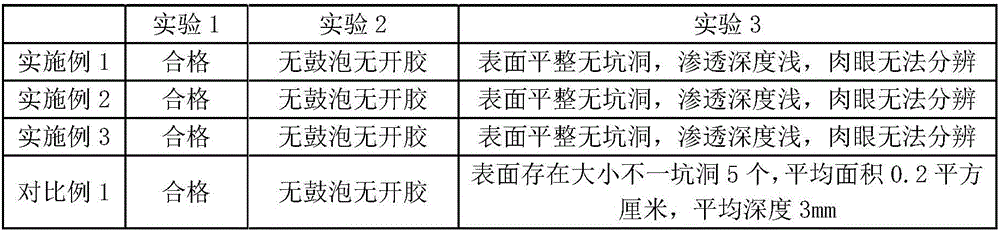

Examples

specific Embodiment 1

[0033] The weight components of multi-purpose spray glue are as follows:

[0034] SBR rubber (SBR1712): 7 parts;

[0035] Dimethyl carbonate: 38 parts;

[0036] Disproportionated rosin: 14 parts;

[0037] Ethyl acetate: 20 parts;

[0038] C 5 Petroleum resin: 3 parts;

[0039] Polyvinyl alcohol with a number average molecular weight of 16000-20000: 1 part by weight;

[0040] Hydroxyethyl methacrylate: 5 parts by weight;

[0041] Butane: 18 parts.

[0042] The preparation method is:

[0043] Step 1: First add dimethyl carbonate and ethyl acetate into the reaction kettle;

[0044] Step 2: Add SBR rubber, tackifying resin, and disproportionated rosin to the reactor, and stir for 1 hour at room temperature;

[0045] Step 3: Add polyvinyl alcohol and hydroxyethyl methacrylate to the reactor, pressurize it to 0.3MPa (gauge pressure), and react at 65°C for 0.5h;

[0046] Step 4: Cool the reaction kettle to normal temperature and keep it at normal pressure and stir for 2h;

[0047] Step 5: Filter the re...

specific Embodiment 2

[0048] The weight components of multipurpose spray glue are as follows:

[0049] SBR rubber (SBR1712): 9 parts;

[0050] Dimethyl carbonate: 33 parts;

[0051] Disproportionated rosin: 16 parts;

[0052] Ethyl acetate: 22 parts;

[0053] C 9 Petroleum resin: 2 parts;

[0054] Polyvinyl alcohol with a number average molecular weight of 16000-20000: 2 parts by weight;

[0055] Hydroxyethyl methacrylate: 31 parts by weight;

[0056] Butane: 16 parts.

[0057] The preparation method is: Step 1: First add dimethyl carbonate and ethyl acetate to the reaction kettle;

[0058] Step 2: Add SBR rubber, tackifier resin, and disproportionated rosin to the reactor, and stir for 1.5h at room temperature;

[0059] Step 3: Add polyvinyl alcohol and hydroxyethyl methacrylate to the reactor, pressurize it to 0.5MPa (gauge pressure), and react at 60°C for 0.5h;

[0060] Step 4: Cool the reactor to normal temperature and keep it under normal pressure and stir for 1 hour;

[0061] Step 5: Filter the reaction produc...

specific Embodiment 3

[0062] The weight components of multi-purpose spray glue are as follows:

[0063] SBR rubber (SBR1500): 8 parts;

[0064] Dimethyl carbonate: 35 parts;

[0065] Disproportionated rosin: 15 parts;

[0066] Ethyl acetate: 21 parts;

[0067] Terpene resin: 2.5 parts;

[0068] Polyvinyl alcohol with a number average molecular weight of 16000-20000: 1.5 parts by weight;

[0069] Hydroxyethyl methacrylate: 4 parts by weight;

[0070] Butane: 17.5 parts.

[0071] The preparation method is specifically:

[0072] Step 1: First add dimethyl carbonate and ethyl acetate into the reaction kettle;

[0073] Step 2: Add SBR rubber, tackifying resin, and disproportionated rosin to the reactor, and stir for 1.2h at room temperature;

[0074] Step 3: Add polyvinyl alcohol and hydroxyethyl methacrylate to the reactor, pressurize it to 0.4MPa (gauge pressure), and react at 62°C for 0.8h;

[0075] Step 4: Cool down the reactor to normal temperature and keep it under normal pressure and stir for 1.5h;

[0076] Step 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com