Low-temperature dry distillation furnace for preparing blue-cokes and preparation method of blue-cokes

A dry distillation furnace and semi-coke technology, which is applied in the field of semi-coke preparation, can solve the problems of excessive air consumption and the inapplicability of low-temperature dry distillation furnaces, and achieve the effects of reducing moisture, increasing area utilization, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] When the present invention is in use:

[0037] Step 1: Select the raw coal for preparing semi-coke; carry out preliminary drying and screening of the raw coal. Since the carbonization furnace of the present invention can dry-distill raw coal with a particle size of 0-120mm, it is not necessary to screen out the raw coal with too small particle size, which saves a lot of manpower and time.

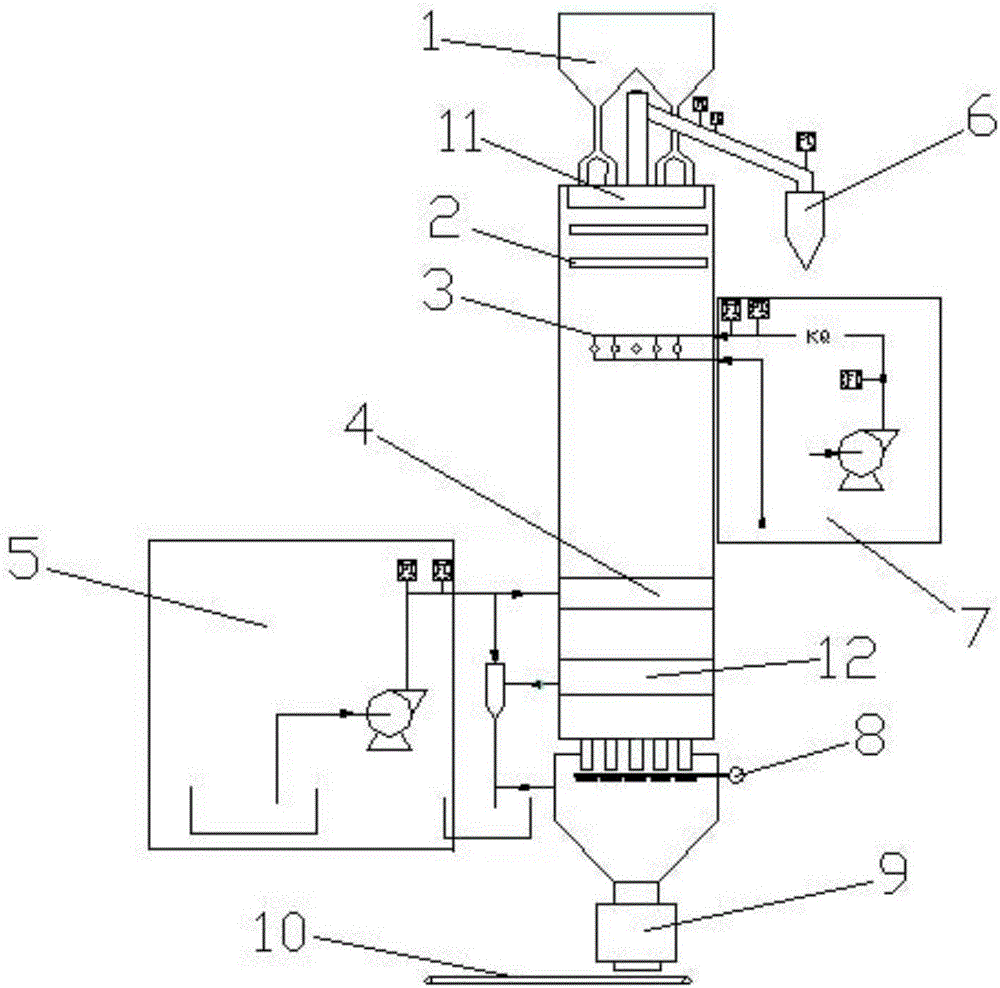

[0038] Step 2: Pour the raw coal obtained in step 1 into the low-temperature carbonization furnace from the coal material inlet 1. Due to the setting of the gas collecting umbrella a11 and the gas guiding umbrella device 2, the raw coal is evenly dispersed and evenly falls into the low-temperature carbonization furnace The dry distillation section in the furnace avoids the accumulation of raw coal with small particle size, and improves the utilization rate of the space in the dry distillation section.

[0039] Subsequently, the raw coal is dry-distilled at 650°C for 2 hours to obtai...

Embodiment 2

[0048] When the present invention is in use:

[0049] Step 1: Select the raw coal for preparing semi-coke; carry out preliminary drying and screening of the raw coal. Since the carbonization furnace of the present invention can dry-distill raw coal with a particle size of 0-120mm, it is not necessary to screen out the raw coal with too small particle size, which saves a lot of manpower and time.

[0050] Step 2: Pour the raw coal obtained in step 1 into the low-temperature carbonization furnace from the coal material inlet 1. Due to the setting of the gas collecting umbrella a11 and the gas guiding umbrella device 2, the raw coal is evenly dispersed and evenly falls into the low-temperature carbonization furnace The dry distillation section in the furnace avoids the accumulation of raw coal with small particle size, and improves the utilization rate of the space in the dry distillation section.

[0051] Subsequently, the raw coal was dry-distilled at 750°C for 2 hours to obta...

Embodiment 3

[0060] When the present invention is in use:

[0061] Step 1: Select the raw coal for preparing semi-coke; carry out preliminary drying and screening of the raw coal. Since the carbonization furnace of the present invention can dry-distill raw coal with a particle size of 0-120mm, it is not necessary to screen out the raw coal with too small particle size, which saves a lot of manpower and time.

[0062] Step 2: Pour the raw coal obtained in step 1 into the low-temperature carbonization furnace from the coal material inlet 1. Due to the setting of the gas collecting umbrella a11 and the gas guiding umbrella device 2, the raw coal is evenly dispersed and evenly falls into the low-temperature carbonization furnace The dry distillation section in the furnace avoids the accumulation of raw coal with small particle size, and improves the utilization rate of the space in the dry distillation section.

[0063] Subsequently, the raw coal is dry-distilled at 700°C for 2 hours to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com