Manufacturing method of sealing brush and sealing brush obtained by the method

A manufacturing method and sealing brush technology, which are applied in textiles, papermaking, packaging, woven fabrics, etc., can solve problems such as hindering development, complex manufacturing process of sealing brushes, and high manufacturing costs, and achieve simplified production processes, light weight, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

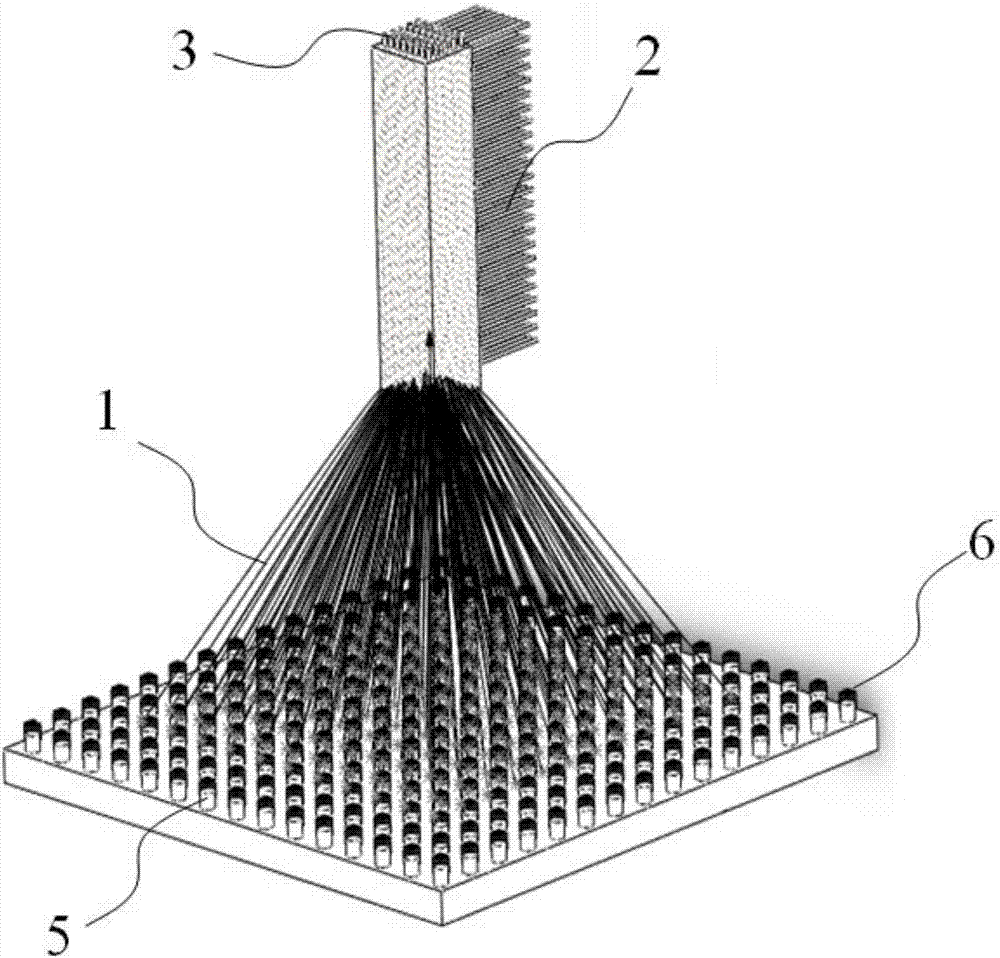

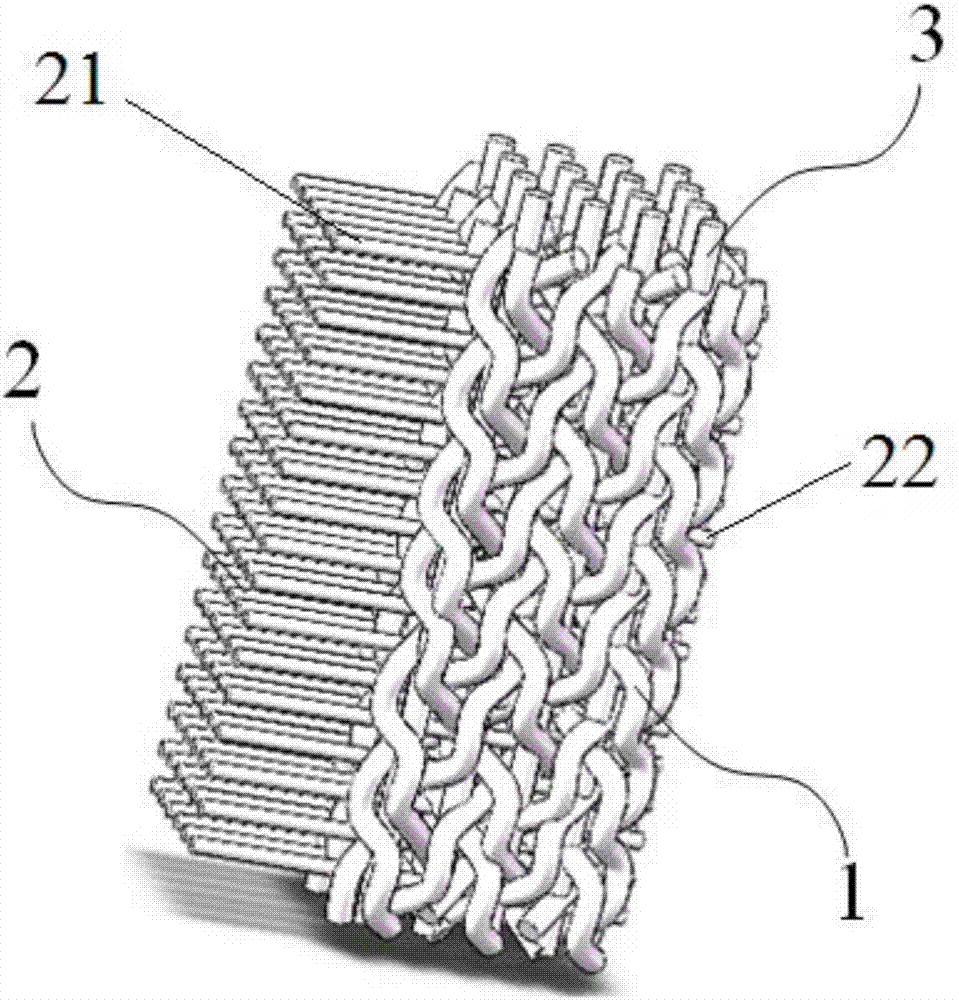

[0029] Embodiment 1 (see Figure 1-4 )

[0030] The weaving yarn 1, the brush filament (six-directional yarn) 2 and the shaft yarn 3 all adopt hollow quartz fibers of 190tex; the weaving parameters are: the cross-section of the substrate is rectangular; the cross-sectional size is 10mm×6mm; the weaving yarn 1, the brush filament 2 and The fineness of the shaft yarn 3 is 190tex×2 plied, the length of the flower node is 5.0mm / piece; the braiding angle is 26°; the yarn arrangement of the substrate 4 is 11 columns×(6 rows of knitting yarns+5 rows of shaft yarns), The fabric structure is a three-dimensional six-direction structure, and the sixth-direction yarn is the brushing direction.

[0031] (1) Before weaving, the knitting yarn carrier 5 and the shaft yarn carrier 6 are arranged in rows and columns according to the shape (rectangular shape) of the seal brush cross section to form a basic array. One end of braided yarn 1 is connected with braided yarn carrier 5, and the other...

Embodiment 2

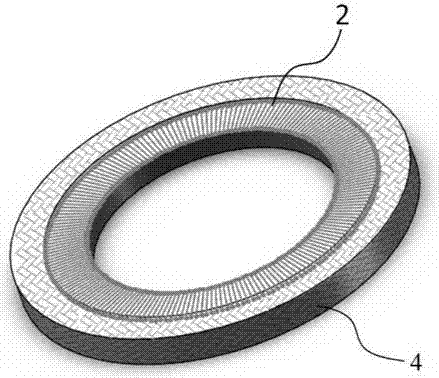

[0034] Embodiment 2 (see figure 1 , 5 、6)

[0035] The weaving yarn 1, the brush filament (five-way yarn) 2 and the shaft yarn 3 are all made of 190tex hollow quartz fiber; the weaving parameters are: the cross section of the substrate is T-shaped, which can be regarded as a combination of two rectangles, and the dimensions are 4mm× 30mm and 6mm×8mm; the fineness of weaving yarn 1, brush filament 2 and shaft yarn 3 are all 190tex×2, and the length of flower knots is 4.0mm / piece; the braiding angle is 30°; the substrate yarns are arranged in 8 columns× 4 rows of weaving yarns + 8 columns x 6 rows of weaving yarns; the fabric structure is a three-dimensional five-directional structure, and the fifth directional yarn is the brushing direction.

[0036] (1) Before weaving, the knitting yarn carrier 5 and the shaft yarn carrier 6 are arranged in rows and columns according to the shape (T shape) of the seal brush cross section to form a basic array. One end of braided yarn 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com