Cotton cloth color-fastness-to-water grading standard sample and preparation method thereof

A standard sample and color fastness technology, applied in the preparation of test samples, color/spectral characteristic measurement, etc., can solve problems such as difficulty in ensuring the accuracy and consistency of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

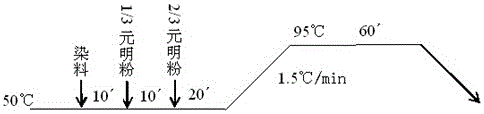

Embodiment 1

[0074] Cotton cloth color fastness graded standard sample, the color fastness to water of the standard sample is graded 4 to 5 as it is for discoloration, 2 to 4 for cotton lining, and 2 to 4 for wool lining. The numbers range from 3 to 5. The specific preparation method is as follows:

[0075] 1) Gray cloth: Choose pure cotton woven plain gray cloth with relatively flat surface and less surface defects. The parameters of the gray cloth are: warp density 86 threads / inch, weft density 60 threads / inch, warp and weft yarn count 40Ne, square meter weight 100g / ㎡, width 90cm.

[0076] 2) Pretreatment: raw fabric preparation, singeing, desizing, scouring, bleaching;

[0077] Singeing: Gas singeing machine is adopted, and the technological process is: cloth feeding → brushing → singeing → fire extinguishing → cloth falling, and the singeing series reaches 3-4 levels.

[0078] Pre-treatment process of annealing, boiling and bleaching: the one-bath pre-treatment process of alkali oxy...

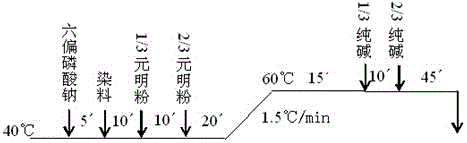

Embodiment 2

[0117] Cotton cloth color fastness graded standard sample, the color fastness to water of the standard sample is graded 4 to 5 as it is for discoloration, 2 to 4 for cotton lining, and 2 to 4 for wool lining. The numbers range from 3 to 5. The specific preparation method is as follows:

[0118] 1) Gray cloth: Choose pure cotton woven plain gray cloth with relatively flat surface and less surface defects. The parameters of the gray cloth are: warp density 84 threads / inch, weft density 60 threads / inch, warp and weft yarn count 32Ne, square meter weight 112g / ㎡, width 90cm.

[0119] 2) Pretreatment: raw fabric preparation, singeing, desizing, scouring, bleaching;

[0120] Singeing: Gas singeing machine is adopted, and the technological process is: cloth feeding → brushing → singeing → fire extinguishing → cloth falling, and the singeing series reaches 3-4 levels.

[0121] Pre-treatment process of annealing, boiling and bleaching: the one-bath pre-treatment process of alkali oxy...

Embodiment 3

[0160]Cotton cloth color fastness graded standard sample, the color fastness to water of the standard sample is graded 4 to 5 as it is for discoloration, 2 to 4 for cotton lining, and 2 to 4 for wool lining. The numbers range from 3 to 5. The specific preparation method is as follows:

[0161] 1) Gray cloth: Choose pure cotton woven plain gray cloth with relatively flat surface and less surface defects. The parameters of the gray cloth are: warp density 76 threads / inch, weft density 54 threads / inch, warp and weft yarn count 40Ne, square meter weight 102g / ㎡, width 90cm.

[0162] 2) Pretreatment: raw fabric preparation, singeing, desizing, scouring, bleaching;

[0163] Singeing: Gas singeing machine is adopted, and the technological process is: cloth feeding → brushing → singeing → fire extinguishing → cloth falling, and the singeing series reaches 3-4 levels.

[0164] Pre-treatment process of annealing, boiling and bleaching: the one-bath pre-treatment process of alkali oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com