Gas treating system applicable to online carbon dioxide measuring

A gas processing system, carbon dioxide technology, applied in the field of measurement, can solve the problems of time-consuming, labor-intensive, cumbersome, and easy to introduce errors in sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

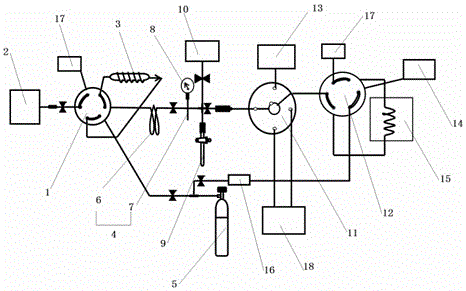

[0014] figure 1 A specific embodiment of a gas processing system suitable for on-line measurement of carbon dioxide of the present invention is shown: a gas processing system suitable for on-line measurement of carbon dioxide includes a carbon dioxide gas separation and collection unit and a micro-control injection unit, wherein the carbon dioxide gas separation and collection The unit includes the first two-position six-way selection valve 1, the first two-position six-way selection valve 1 is respectively connected to the elemental analyzer 2, the carbon dioxide molecular sieve 3, the vacuum pipeline 4, and the helium cylinder 5. The two ends of the carbon dioxide molecular sieve 3 are respectively connected to the second The two interfaces on the first two-position six-way selector valve 1 are connected, the vacuum pipeline 4 includes a connected double-ring cold trap tube 6 and a cross quantitative tube 7, and the other end of the double-ring cold trap tube 6 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com