Ultrathin bi-directional sound obstruction channel

A channel, ultra-thin technology, applied in the direction of sounding equipment, instruments, etc., can solve the problems of large volume, short life cycle, and easy to be affected by the external environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

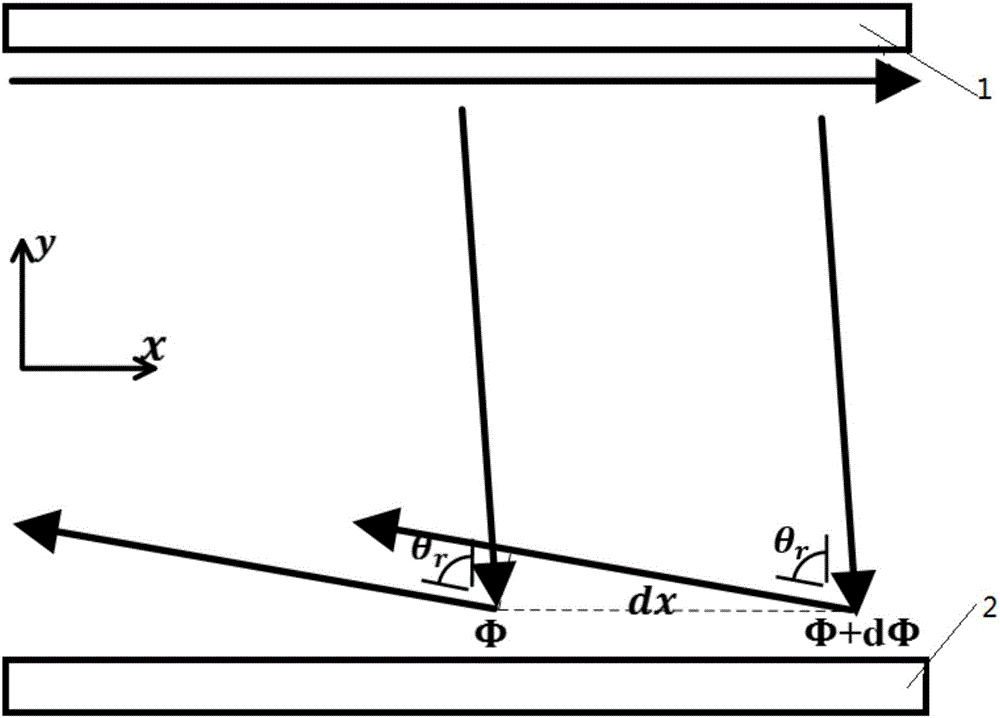

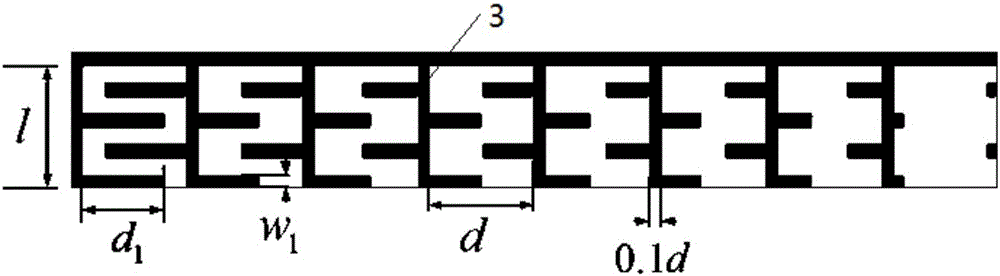

[0036] Example: such as figure 1 and figure 2 As shown, a kind of ultra-thin two-way sound barrier channel, comprises upper metasurface 1 and lower metasurface 2 that are arranged in parallel, and upper metasurface 1 and lower metasurface 2 opposite faces are symmetrically installed with four groups of folded structures 3, so The folding structure 3 includes nine partitions arranged side by side, and cavities are formed between adjacent partitions, forming eight cavities in total, and beams are alternately distributed on the partitions in the cavities, and the height l of the partitions is 1cm, the width d of the cavity is 1cm, the thickness w of the beam 1 is 0.1cm, the longitudinal spacing of the beams is 0.15cm, and the length d of the beams in each cavity in the folded structure 3 1 The order is (0.78, 0.583, 0.53, 0.48, 0.42, 0.382, 0.33, 0.1) cm.

[0037] The upper and lower surfaces of the pipeline are folded structure 3 materials placed symmetrically. The overall n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com