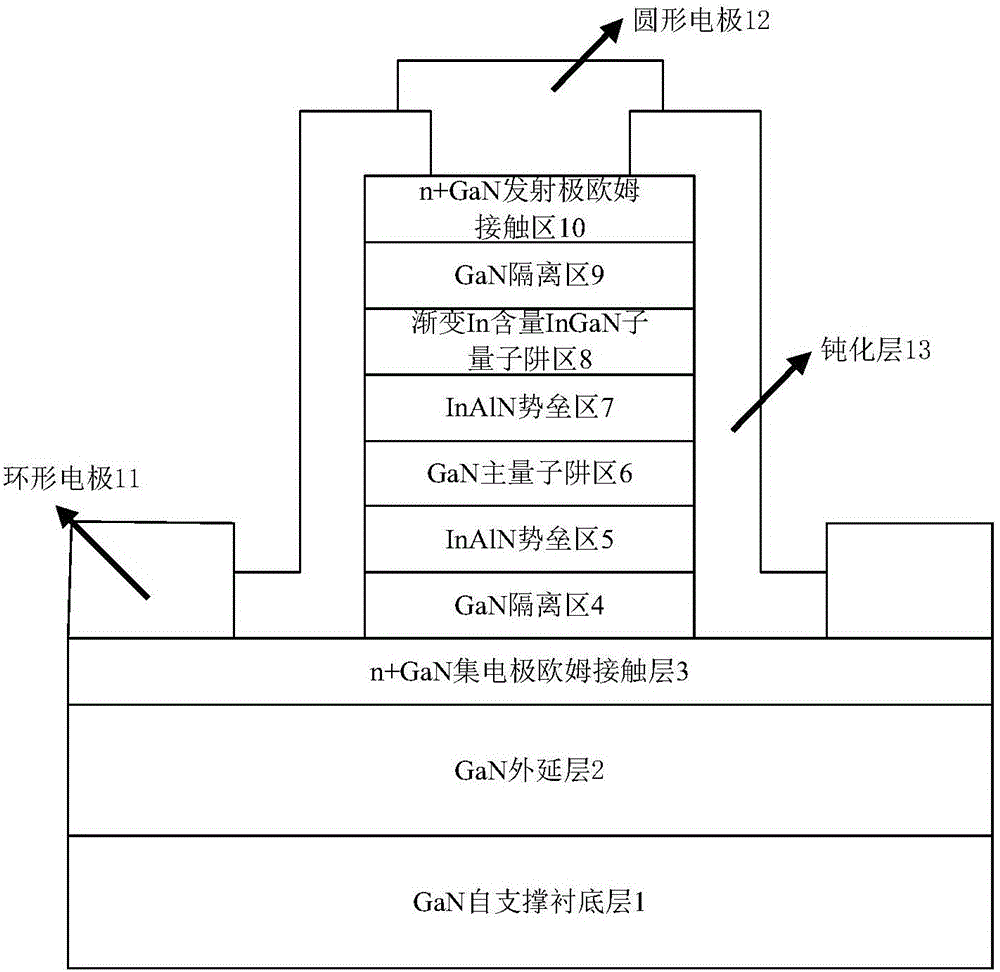

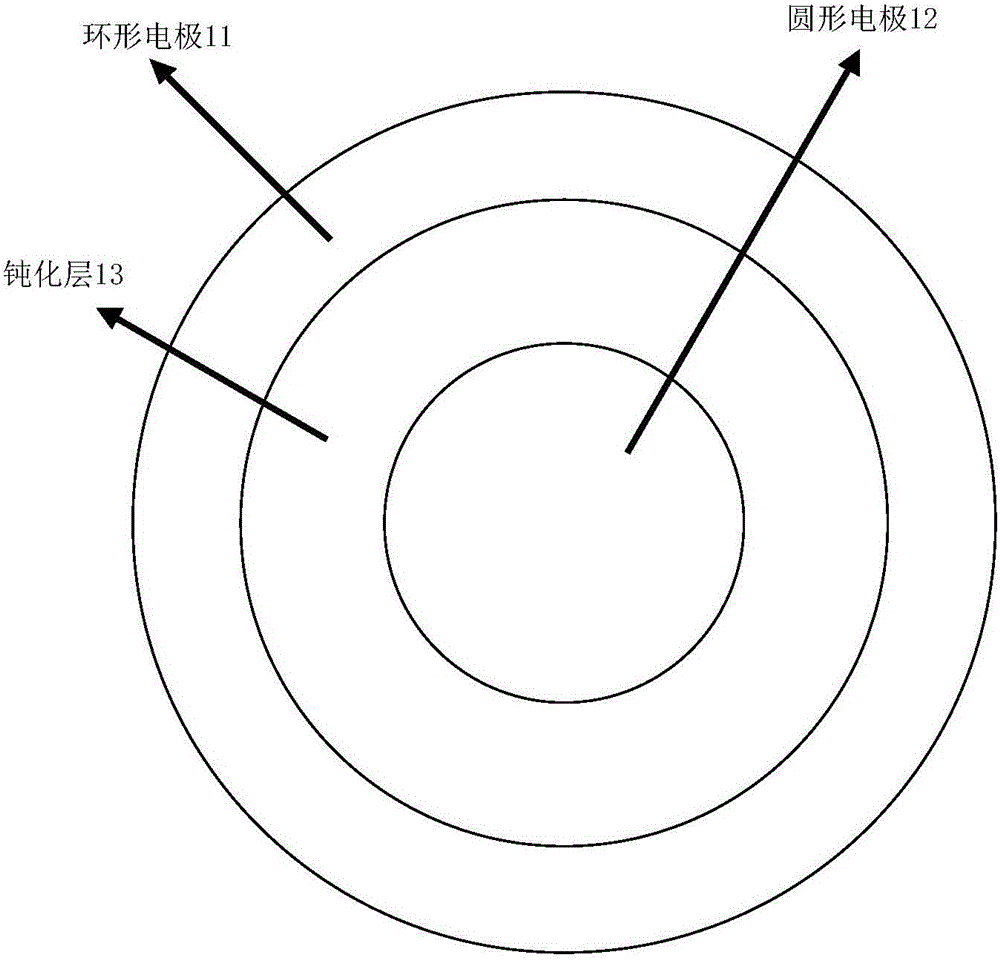

RTD with InGaN sub quantum well with gradually changing In component

A quantum well and diode technology, applied in the field of electronics, can solve problems such as low mobility, low two-dimensional electron gas concentration, operating frequency and output power that cannot meet the output requirements of terahertz devices, etc., to overcome large and small leakage currents. Effect of leakage current, high peak current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

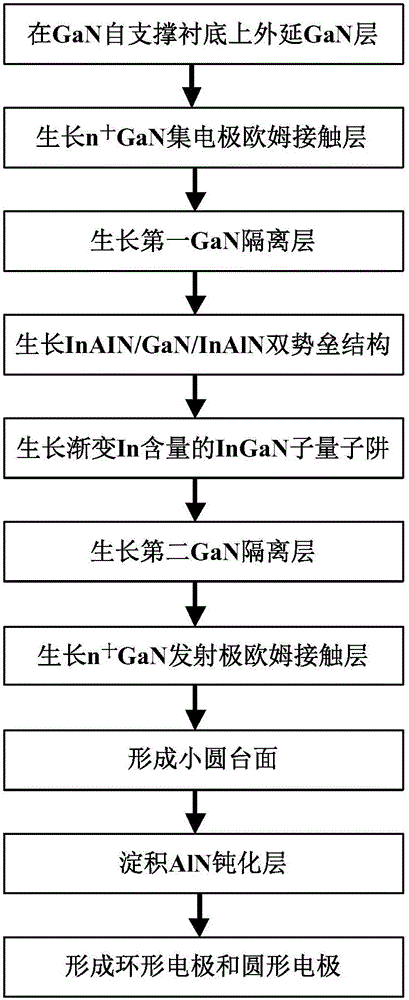

Method used

Image

Examples

Embodiment 1

[0139] Embodiment 1: The In composition of making the first layer InGaN sub-quantum well is 3%, the In composition of the second layer InGaN sub-quantum well is 4%, and the In composition of the third layer InGaN sub-quantum well is 5%. Gradient In composition InGaN sub-quantum well layer.

[0140] Step 1: Epitaxial GaN layer on GaN free-standing substrate.

[0141] A layer of GaN is epitaxially grown on the substrate by metal-organic chemical vapor deposition (MOCVD).

[0142] The specific steps of the metal organic chemical vapor deposition MOCVD method are as follows.

[0143] Prepare the source, use triethylgallium as the gallium source, and high-purity nitrogen as the nitrogen source.

[0144] The gas in the reaction chamber is pumped out, and the substrate is sent into the reaction chamber.

[0145] The temperature in the reaction chamber was raised to a growth temperature of 450° C., and the pressure was 40 Torr.

[0146] After the temperature is reached, the galliu...

Embodiment 2

[0235] Embodiment 2: The In composition of making the first layer InGaN sub-quantum well is 4%, the In composition of the second layer InGaN sub-quantum well is 5%, and the In composition of the third layer InGaN sub-quantum well is 6%. Gradient In composition InGaN sub-quantum well layer.

[0236] Step A: Epitaxial GaN layer on GaN free-standing substrate.

[0237] A layer of GaN is epitaxially grown on the substrate by metal-organic chemical vapor deposition (MOCVD).

[0238] The specific steps of the metal organic chemical vapor deposition MOCVD method are as follows.

[0239] Prepare the source, use triethylgallium as the gallium source, and high-purity nitrogen as the nitrogen source.

[0240] The gas in the reaction chamber is pumped out, and the substrate is sent into the reaction chamber.

[0241] The temperature in the reaction chamber was raised to a growth temperature of 450° C., and the pressure was 40 Torr.

[0242] After the temperature is reached, the gallium ...

Embodiment 3

[0331] Embodiment 3: The In composition of making the first layer InGaN sub-quantum well is 5%, the In composition of the second layer InGaN sub-quantum well is 6%, and the In composition of the third layer InGaN sub-quantum well is 7%. Gradient In composition InGaN sub-quantum well layer.

[0332] Step 1: Epitaxial GaN layer on GaN free-standing substrate.

[0333] A layer of GaN is epitaxially grown on the substrate by metal-organic chemical vapor deposition (MOCVD).

[0334] The specific steps of the metal organic chemical vapor deposition MOCVD method are as follows.

[0335] Prepare the source, use triethylgallium as the gallium source, and high-purity nitrogen as the nitrogen source.

[0336] The gas in the reaction chamber is pumped out, and the substrate is sent into the reaction chamber.

[0337] The temperature in the reaction chamber was raised to a growth temperature of 450° C., and the pressure was 40 Torr.

[0338] After the temperature is reached, the galliu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com