A cam type sprinkler

A sprinkler irrigation and cam-type technology, which is applied in watering devices, gardening, agriculture, etc., can solve the problem of overlapping irrigation surfaces, waste of irrigation dead ends, no significant improvement in the uniformity of sprinkler irrigation, and inability to solve the problem of overlap of sprinkler irrigation surfaces, etc. problems, to achieve the effect of ensuring water source, improving stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

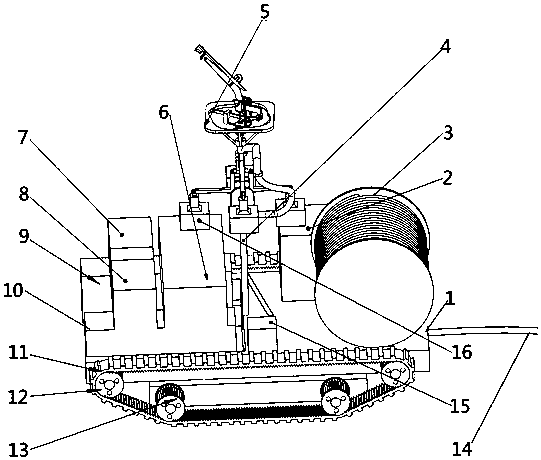

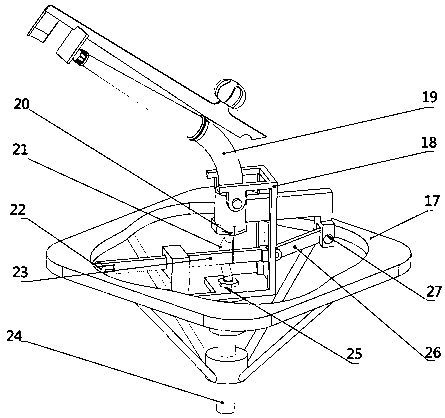

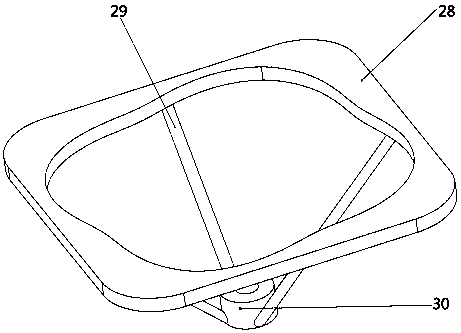

[0039] Embodiment 1: as Figure 1-10 As shown, the cam type sprinkler includes frame 1, water pump assembly 2, reel assembly 3, hard water pipe I4, cam sprinkler head 5, battery 6, drive motor I7, drive motor II8, gearbox I9, gearbox II10 , crawler belt 11, driving track wheel 12, driven track wheel 13, reel water pipe 14, balance device 16; the two crawler belts 11 are respectively installed on both sides of frame 1 by driving track wheel 12 and driven track wheel 13, The active track wheels 12 on both sides of the frame 1 are respectively connected with the gearbox I9 and the gearbox II10 located at the front end of the frame 1, and the drive motor I7 and the drive motor II8 are arranged above the gearbox I9 and the gearbox II10 and connected with the gearbox I9, The gearbox II10 is connected, the water pump assembly 2 is installed at the rear end of the frame 1, the battery 6 is installed on the frame 1 and is located behind the drive motor I7 and the drive motor II8, and t...

Embodiment 2

[0048] Embodiment 2: The structure of the device in this embodiment is the same as in Embodiment 1, the difference is that the device also includes a conventional wireless signal receiving control device 15, and the wireless signal receiving control device 15 is installed in the middle of the frame 1 and is respectively connected to the drive motor I7, drive motor II8, The water pump assembly 2 and the reduction motor 33 are connected to receive remote control signals and control the operation of each motor through conventional techniques.

[0049] In the prior art, most of the ordinary nozzles with a circular sprinkling area will have dead ends when sprinkling square cultivated land, and the waste and overlapping parts are unavoidable. This will not occur when using a cam-type sprinkler with a square sprinkling surface to irrigate square cultivated land. Overlap and dead angle are beneficial to water saving and irrigation uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com