Uniform ammonia spraying system and method for controlling same

A uniform and ammonia gas technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as large value, increased ammonia escape, and low ammonia injection volume, so as to reduce the occurrence of clogging and reduce Effect of ammonia escape and reduction of blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

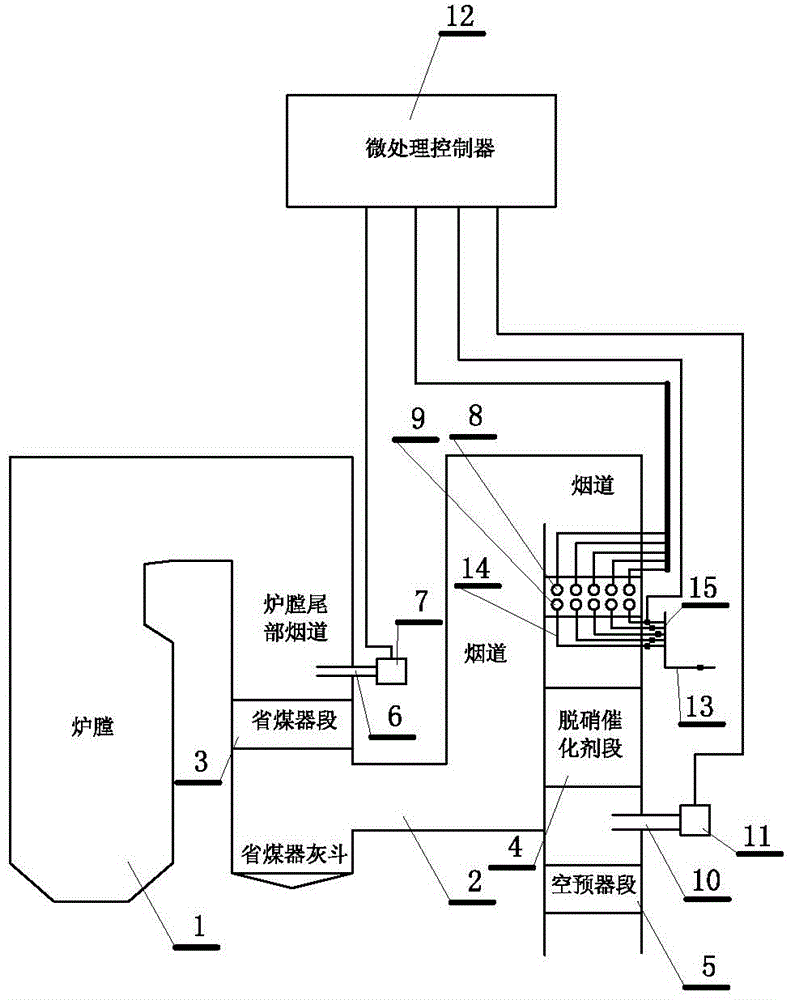

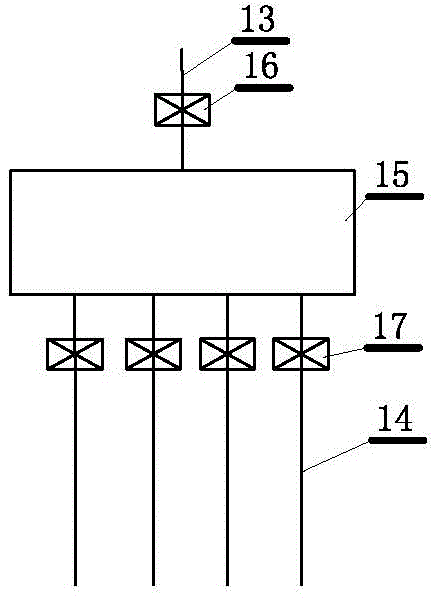

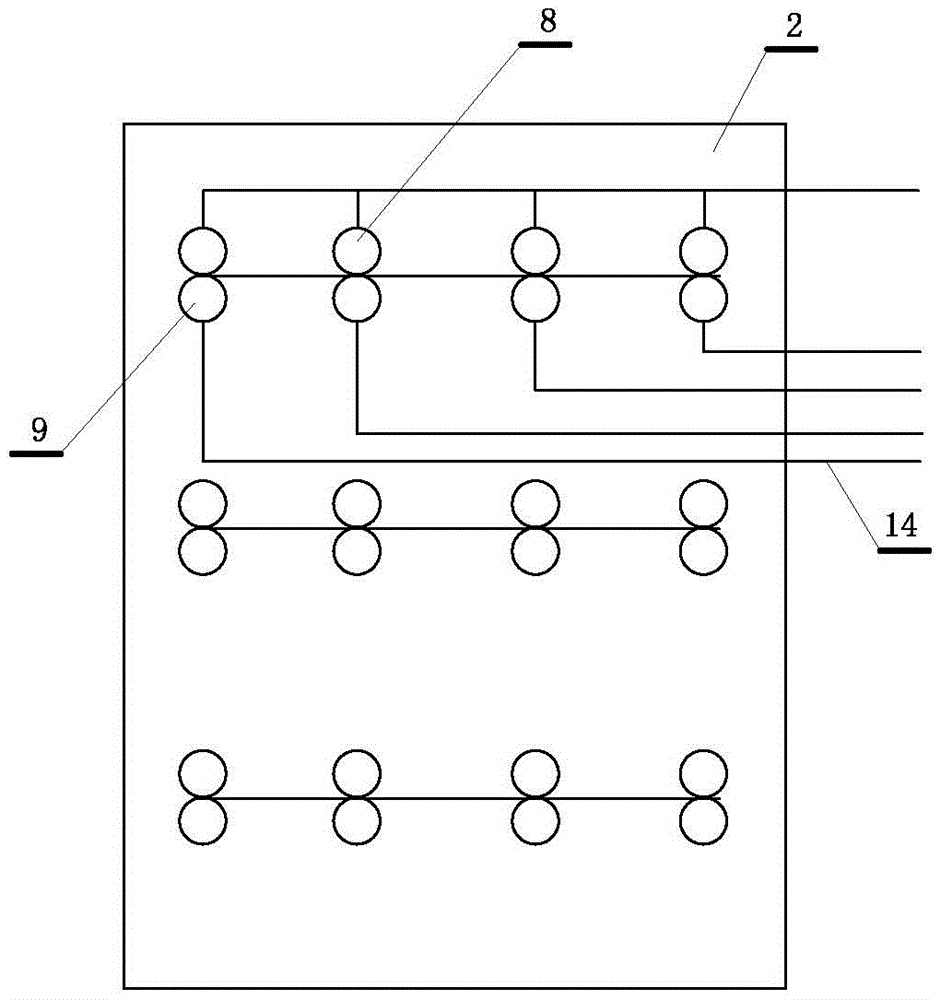

[0022] A uniform ammonia injection system such as figure 1 As shown, it includes a square flue 2 connected to the furnace outlet of the boiler furnace chamber 1. The flue connected to the furnace outlet is called the tail flue of the furnace chamber, and the economizer section 3 and the denitration catalyst section 4 are arranged in sequence in the flue and the air preheating section 5; wherein, in the flue between the furnace outlet and the economizer section, a first flue gas sampling port 6 is arranged close to the front end of the economizer section, and the first sampling port is connected to a NO X (nitrogen oxides) measuring device 7 to measure the initial NO at the furnace outlet X (nitrogen oxide) content, in the flue between the economizer section and the denitration catalyst section, a plurality of flue gas flow rate sensors 8 are arranged at different positions in the vertical section, and are distributed on the same vertical section There are a plurality of ammon...

Embodiment 2

[0031]A uniform ammonia injection control method based on the uniform ammonia injection system described in embodiment 1, so the content of embodiment 1 should also be regarded as the content of this embodiment, wherein the system includes a boiler furnace outlet connected A square flue, in which an economizer section, a denitrification catalyst section, and an air preheating section are sequentially arranged; a first flue gas sampling port is arranged in the flue between the furnace outlet and the economizer section, and the In the flue between the economizer section and the denitration catalyst section, a plurality of flue gas flow rate sensors are distributed at different positions in the vertical section, and a plurality of ammonia gas nozzles are distributed in the same vertical section. Ammonia gas nozzles are connected to multiple ammonia gas delivery control loops, and a second flue gas sampling port is arranged in the flue between the deactivated catalyst section and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com