Wet method roller type disintegrating mill and grading closed-circuit process thereof

A crushing mill and roller type technology, applied in the field of crushing machinery using grinding discs, can solve the problems of high power consumption and steel consumption, reduce power consumption and steel consumption of grinding, improve grinding efficiency, and increase grinding particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

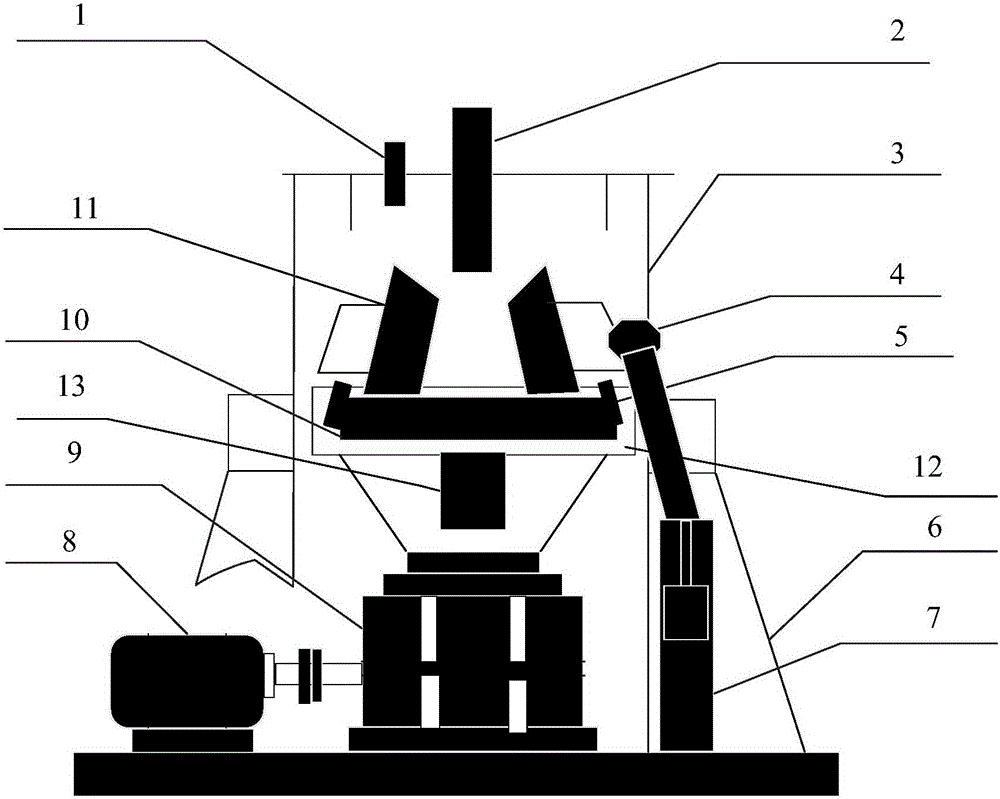

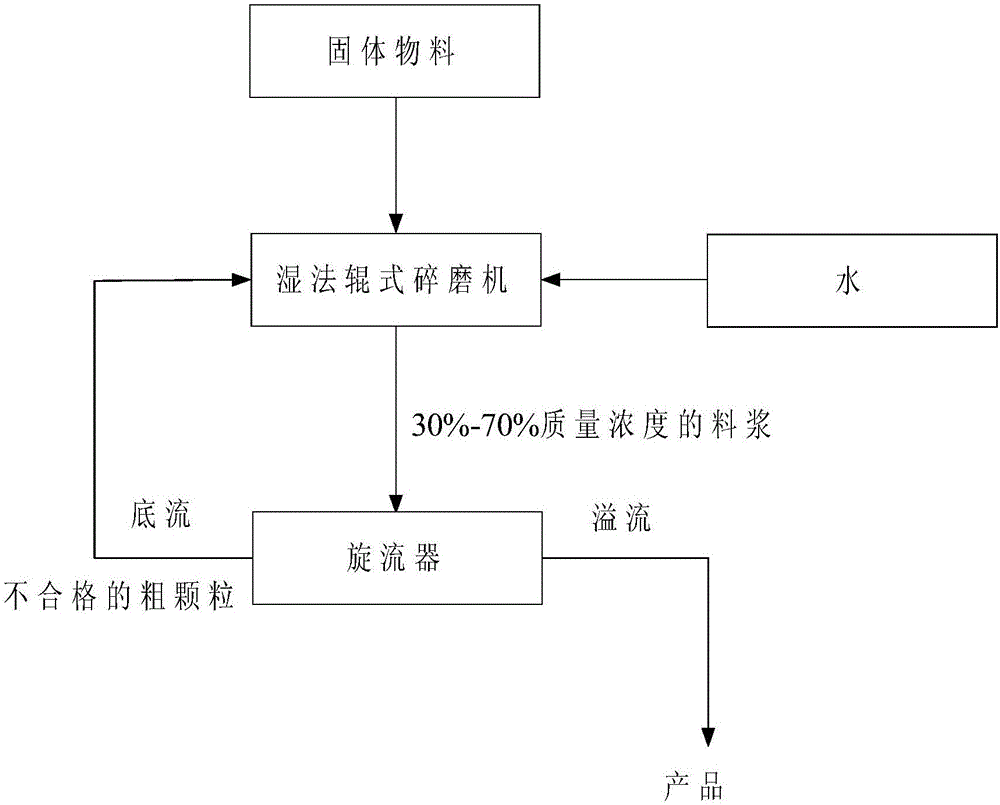

[0031] see figure 1 , a wet roller mill, comprising a grinding disc 10, a grinding roller 11, a motor 8, a hydraulic system 7, and a rocker arm 4; the diameter of the three grinding rollers 11 is 2100mm, and the grinding rollers are located on the grinding disc 10 and are in contact with the grinding disc , the grinding roller 11 is connected with the rocker arm 4, and the rocker arm 4 is connected with the hydraulic system 7; the grinding disc 10 is connected with the motor 8 through the speed reducer 9; the non-porous baffle plate 5 with a height of 100 mm is set on the periphery of the grinding disc; the baffle plate 5 The included angle with the grinding disc plane is 80°; a receiving tank 12 is arranged outside the baffle; the receiving tank 12 is connected to the discharge pipe 13; the slurry in the discharge pipe flows out of the pulverizer.

[0032] An upper housing 3 is covered above the grinding disc, and the upper housing 3 is provided with a water inlet pipe 1 and ...

Embodiment 2

[0038] In the device of this embodiment, a sieve plate is provided on the outer edge of the grinding disc 10, and the included angle between the sieve plate and the plane of the grinding disc is 85°. A straight hole is arranged on the sieve plate, and the diameter of the straight hole is 0.3 mm.

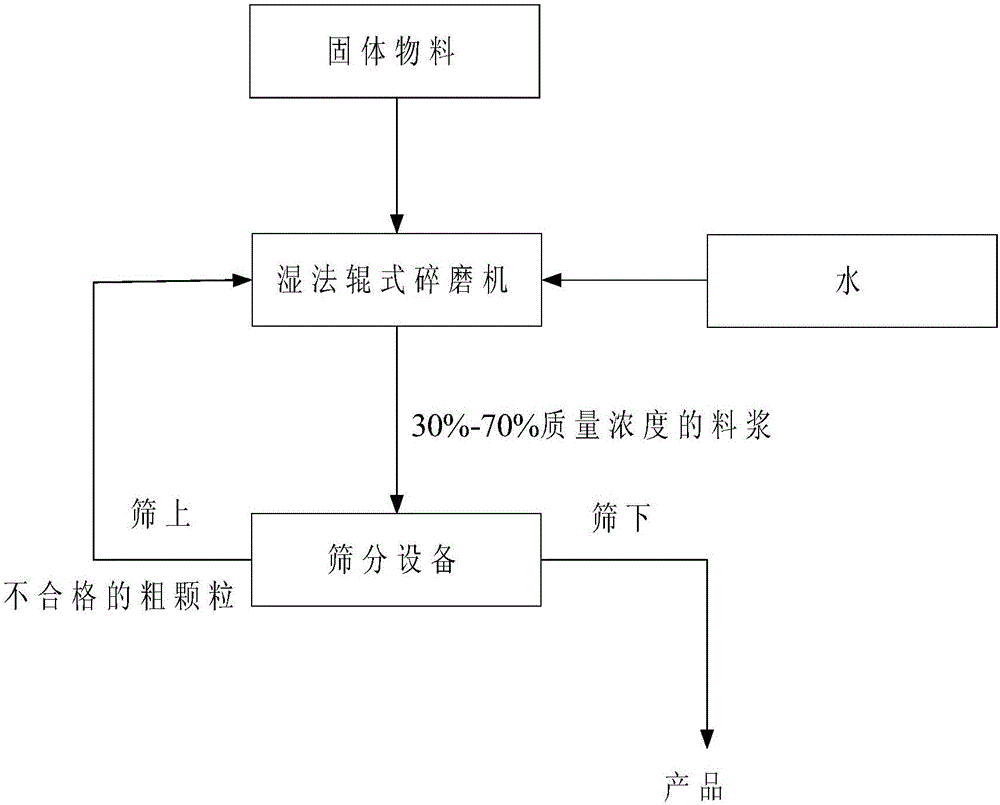

[0039] In this embodiment, the pressure of the hydraulic system is 12MPa, the number of grinding rollers is 4, the diameter of the grinding roller 11 is 2900mm, the material is lead-zinc ore, and the feed particle size is -12mm (below 12mm). Such as image 3 , the external classification adopts screening equipment, and the unqualified coarse material is transported to the wet roller mill by a slurry pump for regrinding.

Embodiment 3

[0041] In this embodiment, the grinding roller of the wet roller crusher adopts the hydraulic system 7 to give pressure to the loading arm 4 of the grinding roller, and the loading arm 4 transmits the pressure to the grinding roller 11. The hydraulic system pressure of the grinding roller 11 is 20MPa, and the grinding roller The number of rollers is 5, the diameter of the grinding roller 11 is 1800mm, the material is graphite ore, the baffle adopts a sieve plate, and the angle between the sieve plate and the plane of the grinding disc is 75°, and the hole of the sieve plate is an enlarged round hole. is 0.2mm, and the hole diameter to the outside of the mill is 0.3mm; if Figure 4 , The external classification adopts a spiral classifier, and the unqualified coarse materials flow out from the bottom of the spiral classifier, and are transported to the wet roller crusher by a slurry pump for regrinding.

[0042] The advantage of using enlarged holes in the sieve plate is that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com