Superfine needle-shaped wollastonite powder production process and device

A technology of wollastonite powder and production device, which is applied in grain processing and other directions, can solve the problems of immature technical equipment and other problems, and achieve the effect of improving aspect ratio and sedimentation value, high aspect ratio and well-preserved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

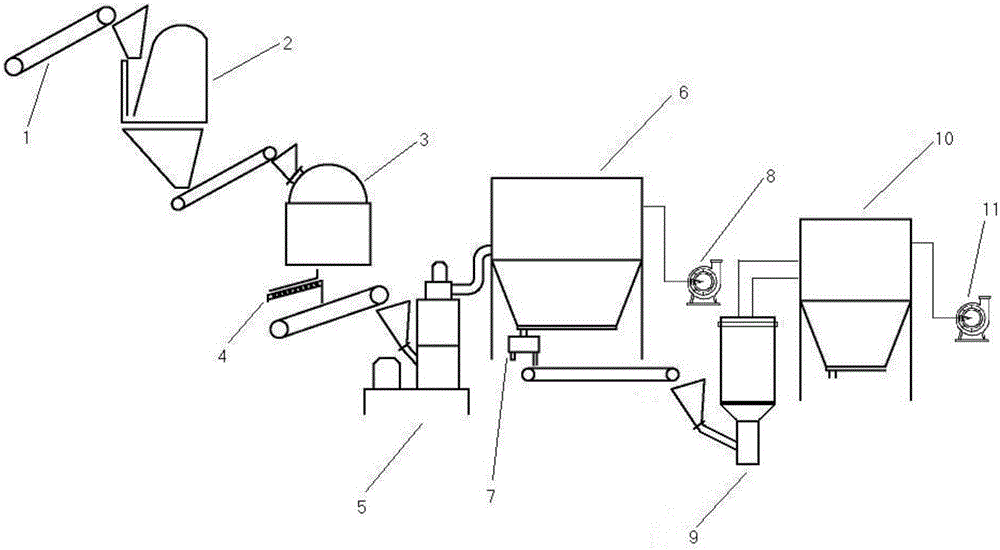

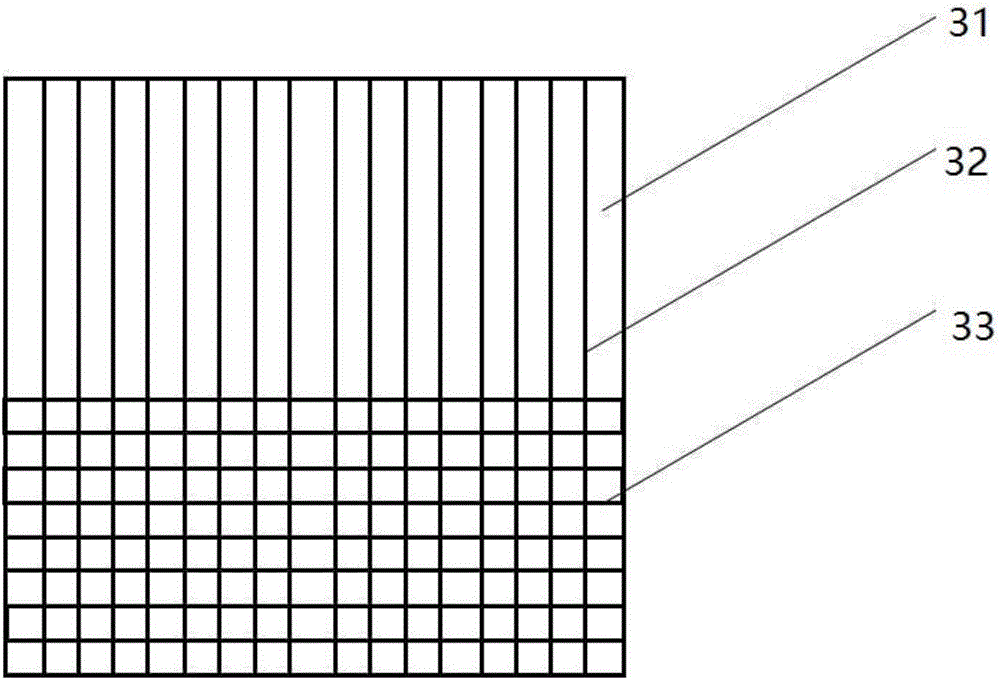

[0063] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

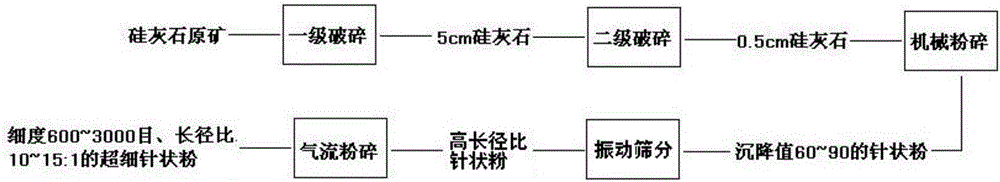

[0064] see figure 1 A kind of superfine acicular wollastonite powder production process of the present invention, comprises the following steps,

[0065]Crushing wollastonite raw ore until the average particle size is less than 1cm, crushing with a pulverizer to obtain needle-shaped powder with a sedimentation value of 60-90, vibrating and sieving the needle-shaped powder to obtain needle-shaped powder with a high aspect ratio, and then Enter the jet mill for jet crushing to obtain acicular wollastonite powder with a fineness of 600-3000 mesh and an aspect ratio greater than 10:1.

[0066] Specifically, it also includes the step of primary crushing the wollastonite raw ore to an average particle size of less than 5 cm, and then sending it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com