High-speed multi-body mechanism driven by cables in parallel

A high-speed, parallel technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high cost, reduced precision of lightweight terminals, and difficulties in processing and manufacturing, and achieve the effect of reducing mass, compact structure, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The working principle of the planar parallel mechanism, which is the core part of this design, will be introduced in detail below in conjunction with the accompanying drawings.

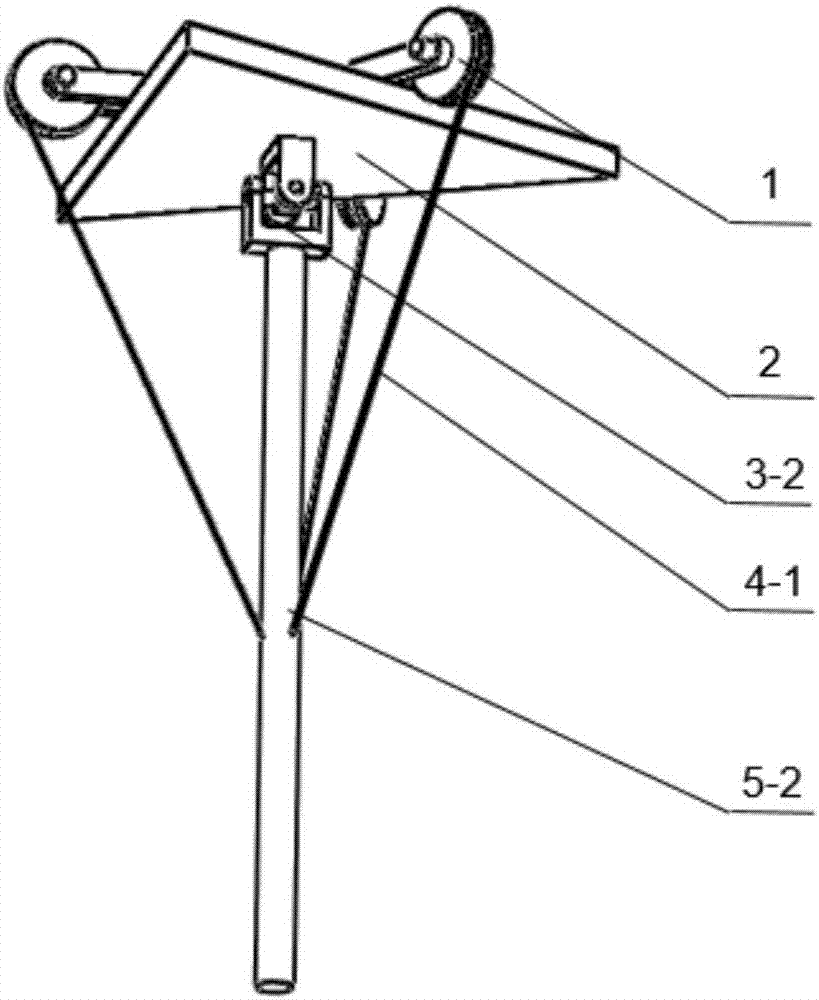

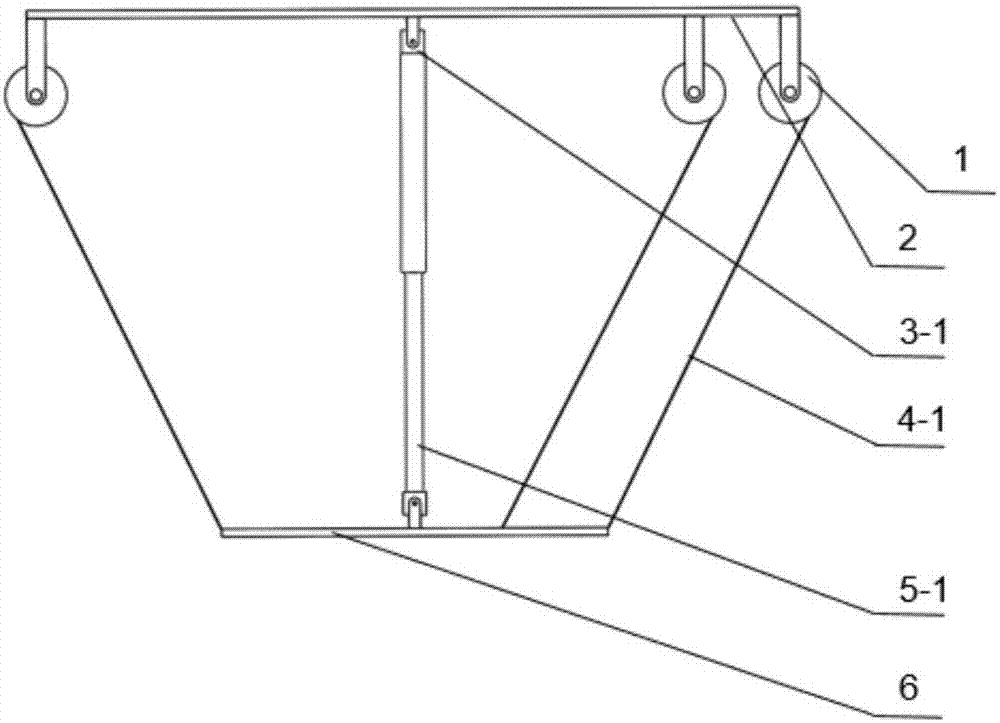

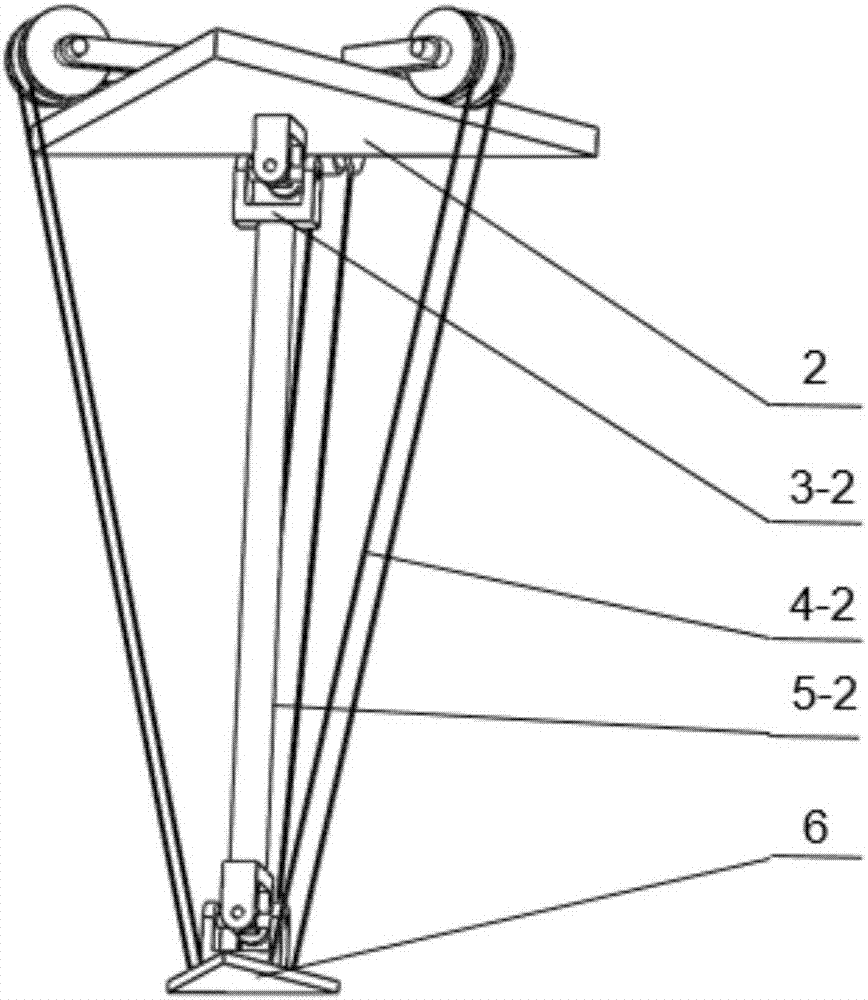

[0027] Such as figure 1 As shown, the cable-driven planar two-degree-of-freedom high-speed multi-body mechanism is composed of a static platform 2, a drum and a driving unit 1, a rope 4-1, a rigid telescopic rod 5-1, a rotating hinge 3-1, and a moving platform 6. The rigid telescopic rod One end of 5-1 is connected with static platform 2 by rotating hinge 3-1, and the other end is connected on the moving platform 6 by rotating hinge 3-1. The drum and drive unit 1 are mounted on a static platform 2 . The rope 4-1 is wound on the drum and the driving unit 1, and the extension and contraction of the rope 4-1 is realized by controlling the rotation of the drum and the driving unit 1. Wherein the two groups of ropes on the right form parallel cable systems to ensure that the dynamic platform 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com