Bending forming structure of light-duty chain guide rail

A bending forming and chain technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of uneven surface quality, many defective products and high wastage rate, and achieve good surface quality, low production cost, high surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

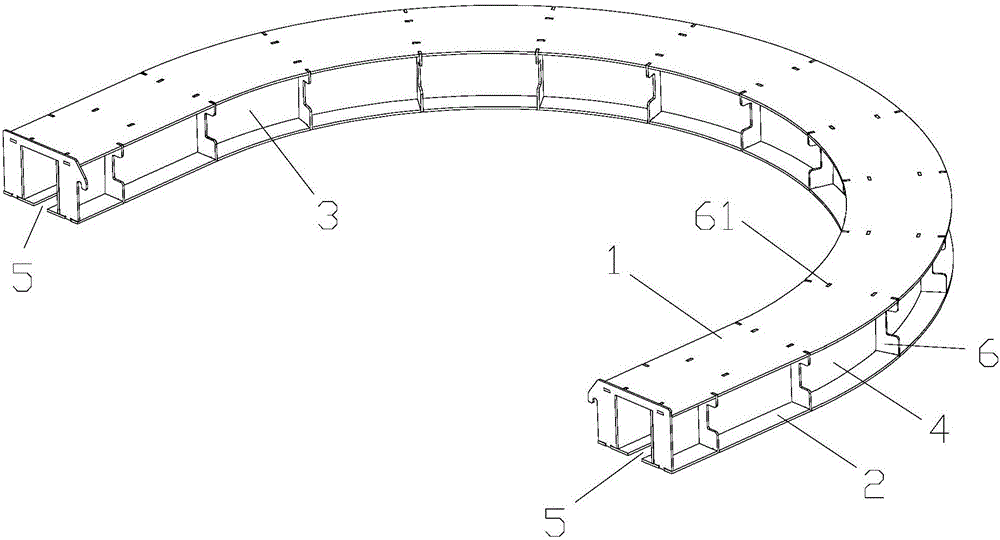

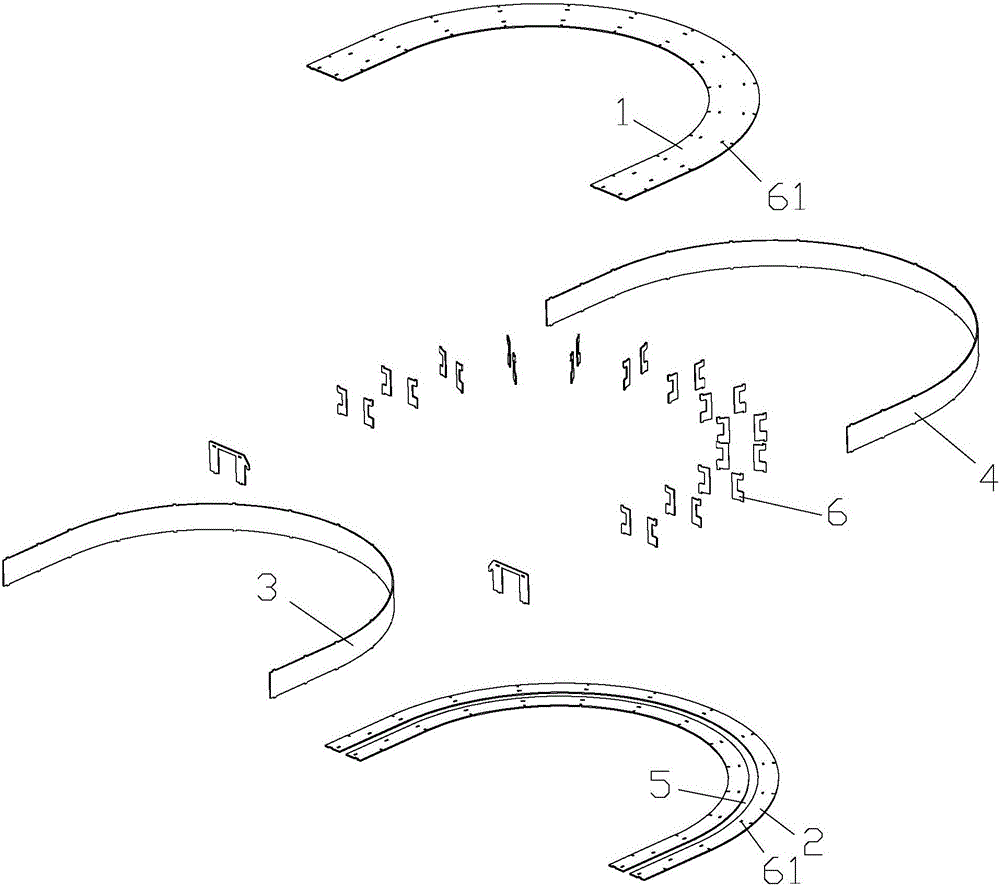

[0019] Implementation method: for figure 1 , figure 2 The scheme of the horizontal curve shown divides the cavity wall of the curved guide rail into five surfaces. The plane of each cavity wall is obtained by precisely cutting the metal plate. The arc curve of the wall is obtained by cutting the metal sheet. The inner and outer (or left and right) side walls are manually bent during welding.

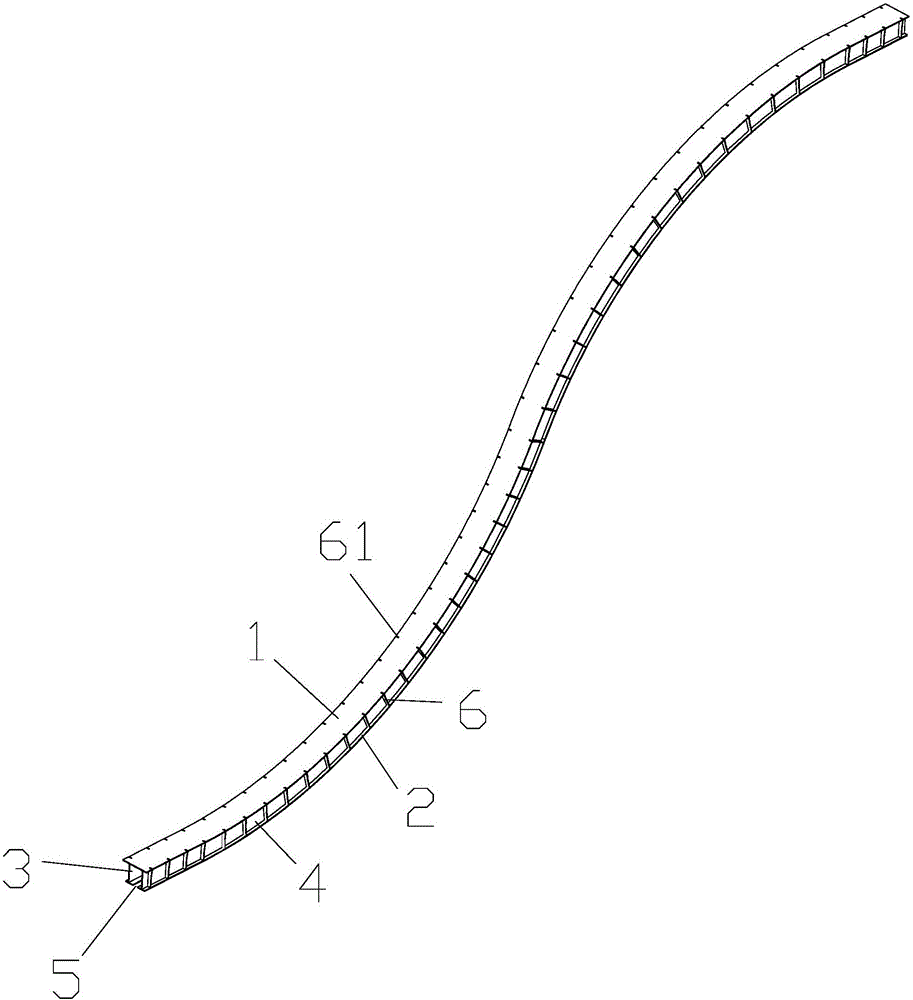

[0020] for image 3 , Figure 4 In the scheme of the vertical curve shown, the curved curves of the upper and lower cavity walls are obtained by manual bending, and the inner and outer (or left and right) side walls are cut from metal plates. The bending positioning is also fixed by mortise and tenon. The final welding is firm.

[0021] The invention disassembles the cavity wall of the curved rail into five surfaces for welding and forming. One group of the two opposite faces of the cavity wall (the open groove surface can be understood as one face) is a plane curved arc shape, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com