Decolorant for textile printing and dyeing wastewater

A technology of textile printing and dyeing and decolorizing agent, which is applied in the direction of textile industry wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of low decolorization efficiency, secondary pollution, high production cost, etc., and achieves the preparation method Simple, high decolorization efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

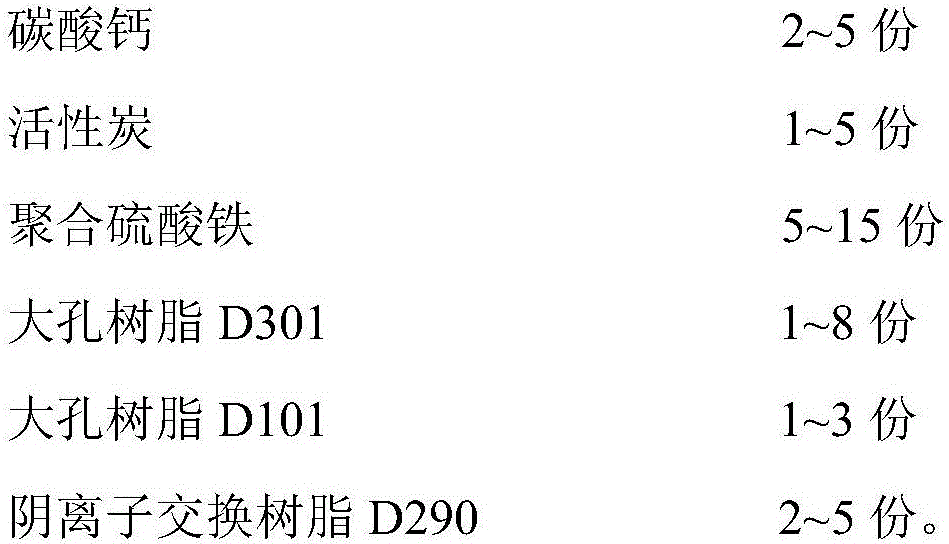

Method used

Image

Examples

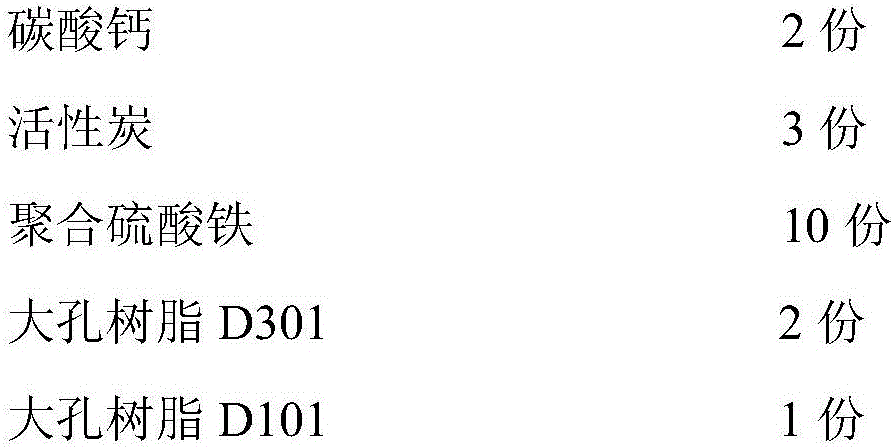

Embodiment 1

[0024] (1) Grind calcium carbonate and gac respectively, and sieve;

[0025] (2) Mix calcium carbonate, activated carbon, polyferric sulfate, macroporous resin D301, macroporous resin D101, and anion exchange resin D290 according to the mass ratio of 2:3:10:2:1 to obtain a mixture, that is, textile printing and dyeing wastewater Depigmentation agent.

Embodiment 2

[0027] (1) Grind calcium carbonate and gac respectively, and sieve;

[0028] (2) Mix calcium carbonate, activated carbon, polyferric sulfate, macroporous resin D301, macroporous resin D101, and anion exchange resin D290 according to the mass ratio of 3:2:15:5:2:2 to obtain a mixture, that is, to obtain a textile Printing and dyeing wastewater decolorizer.

Embodiment 3

[0030] (1) Grind calcium carbonate and gac respectively, and sieve;

[0031] (2) Mix calcium carbonate, activated carbon, polyferric sulfate, macroporous resin D301, macroporous resin D101, and anion exchange resin D290 according to the mass ratio of 1:2:10:5:2:2 to obtain a mixture, that is, to obtain a textile Printing and dyeing wastewater decolorizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com