Device for removing disinfection by-products from water

A technology for disinfection by-products and water removal, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. The effect of clean and civilized production, extended service life and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

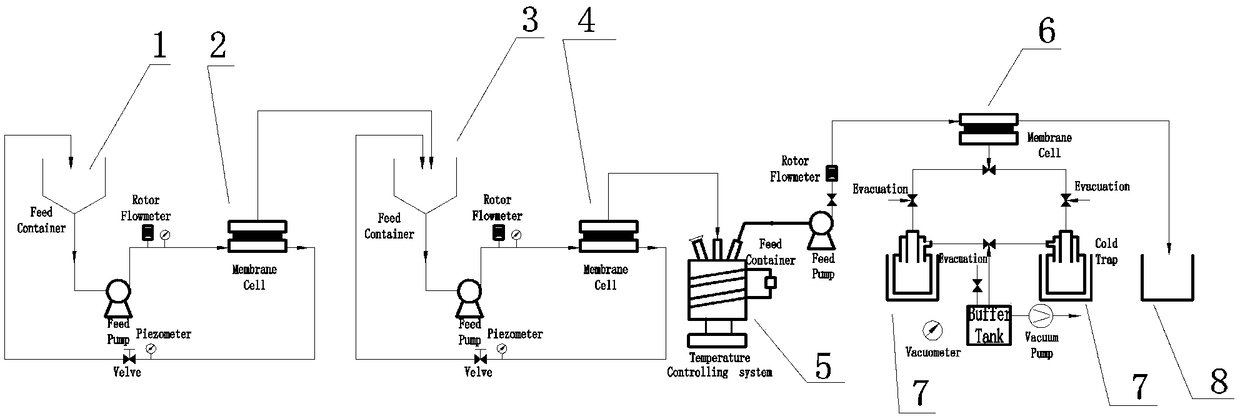

Image

Examples

Embodiment 1

[0068] The water sample to be treated is the swimming pool water after disinfection of a swimming pool, in which the types of DBPs are mainly THMs and HAAs (haloacetic acids), and the THMs and HAAs are between 230μg / L-260μg / L and 140μg / L-420μg / L respectively Fluctuation, the method includes the following steps:

[0069] (1) Enhanced coagulation:

[0070] Adding water to polyferric sulfate with an iron content of 25wt% makes it a coagulant with a concentration of 5 mg / L;

[0071] Add water to cationic polyacrylamide with a molecular weight of 3000kDa to prepare a coagulant aid with a concentration of 20mg / L;

[0072] Put the coagulant and coagulant aid into the water sample to be treated, the dosage is 50mg / L and 0.15mg / L in turn, adjust the pH value to 8 and then stir, the stirring speed is 400r / min, the stirring time for 15 minutes, then let stand for 25 minutes;

[0073] (2) Ultrafiltration:

[0074] The ultrafiltration membrane device 2 comprises an ultrafiltration memb...

Embodiment 2

[0085] The water sample to be treated is tap water in a certain city as an example. THMs and HAAs fluctuate between 10 μg / L-35 μg / L and 1.4 μg / L-4.5 μg / L respectively. The steps of the method are similar to those in Example 1, except that:

[0086] (1) Enhanced coagulation:

[0087] Adding water to polyferric sulfate with an iron content of 15wt% makes it a coagulant with a concentration of 15mg / L;

[0088] Add water to cationic polyacrylamide with a molecular weight of 3000kDa to prepare a coagulant aid with a concentration of 23mg / L;

[0089]Put the coagulant and coagulant aid into the water sample to be treated, the dosage is 40mg / L and 0.10mg / L in turn, adjust the pH value to 7.5 and then stir, the stirring speed is 60r / min, the stirring time for 15 minutes, then let stand for 15 minutes;

[0090] (2) Ultrafiltration:

[0091] The ultrafiltration membrane device 2 comprises an ultrafiltration membrane, and the ultrafiltration membrane is a charge-filled ultrafiltration ...

Embodiment 3

[0099] The water sample to be treated is tap water in a certain city as an example. THMs and HAAs fluctuate between 10 μg / L-35 μg / L and 1.4 μg / L-4.5 μg / L respectively. The steps of the method are similar to those in Example 1, except that:

[0100] (1) Enhanced coagulation:

[0101] Adding water to polyferric sulfate with an iron content of 20wt% makes it a coagulant with a concentration of 15 mg / L;

[0102] Add water to cationic polyacrylamide with a molecular weight of 3000kDa to prepare a coagulant aid with a concentration of 24mg / L;

[0103] Put the coagulant and coagulant into the water sample to be treated, the dosage is 45mg / L and 0.096mg / L in turn, adjust the pH value to 6.41 and then stir, the stirring speed is 200r / min, the stirring time for 20min, then stand still for 20min;

[0104] (2) Ultrafiltration:

[0105] The ultrafiltration membrane device 2 comprises an ultrafiltration membrane, and the ultrafiltration membrane is a charge-filled ultrafiltration membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com