Method for preparing enclosure thermal-insulating composite wall system of steel structure gypsum-based "machine spray-dual free-phase change"

A technology of thermal insulation composite and thermal insulation system, applied in the direction of walls, building components, building structures, etc., can solve the problems of false sense, hanging, fire prevention, etc., to reduce the opening time, improve the comfort, and improve the integrity of the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below.

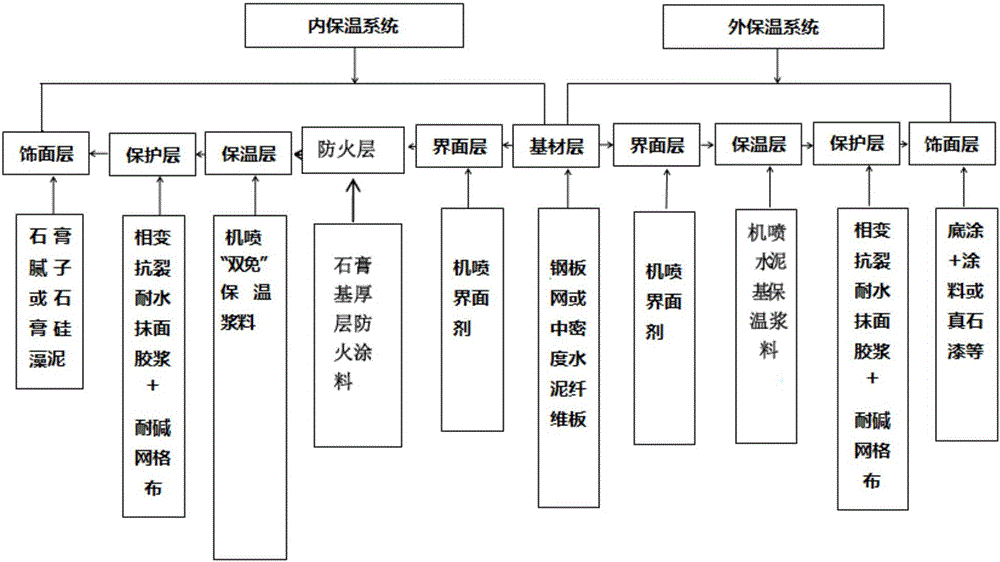

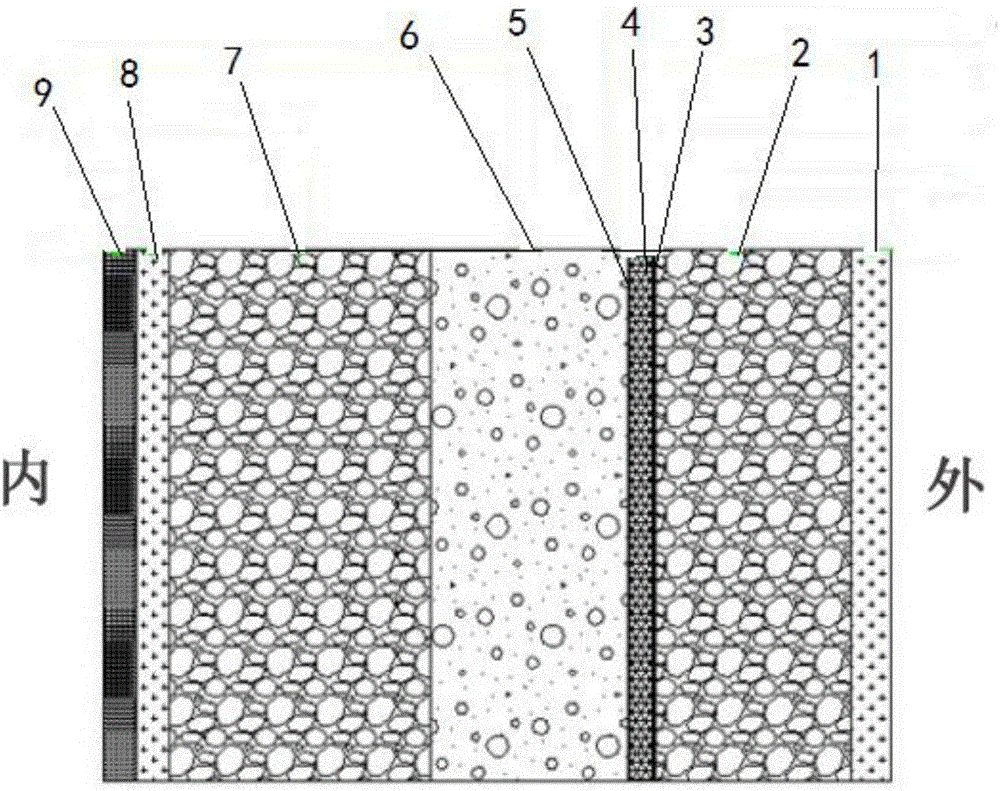

[0040] Such as figure 2 As shown, the present invention discloses a preparation method of a steel structure gypsum-based "machine spray-double-free-phase change" enclosure thermal insulation composite wall system, wherein the thermal insulation composite wall system includes an internal thermal insulation system and an external thermal insulation system, an internal thermal insulation system and an external thermal insulation system. The common base material layer 4 of the external thermal insulation system is as follows from inside to outside: interior surface layer 9, inner protective layer 8, inner thermal insulation layer 7, inner fireproof layer 6, inner interface layer 5, base material layer 4, outer interface layer 3. Outer insulation layer 2, outer protective layer 1, such as figure 1 , the specific preparation method of the thermal insulation composite wall system is as follows:

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com