Self-assembled graphene composite material, and preparation method and application thereof

A composite material and graphene technology, applied in the direction of coating, etc., can solve the problems of not meeting the barrier requirements of small gas molecules, limited improvement of barrier performance, and many composite materials, so as to achieve excellent gas barrier performance, improve barrier performance, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The self-assembled graphene composite material of this embodiment is prepared by the following method:

[0045] 1) Material preparation:

[0046] Disperse 0.1 g of graphene oxide (GO) in water, and ultrasonicate for 30 minutes to obtain a graphene oxide dispersion with a concentration of 1 mg / ml;

[0047] Under magnetic stirring, add 100ml of graphene oxide dispersion to 100ml of polystyrene sodium sulfonate (PSS) solution with a concentration of 3mg / ml (the mass ratio of graphene oxide to polystyrene sodium sulfonate is 1:3), after stirring for 30 minutes for mixing, warm up to 95°C, add 1ml of hydrazine hydrate (1ml of hydrazine hydrate is added for every 0.1g of graphene oxide), after 8 hours of reaction, filter through membrane to remove unreacted PSS, get PSS modified graphene, dispersed in water to obtain a PSS-RGO dispersion with a concentration of 0.5 mg / ml and pH=3;

[0048] Under magnetic stirring, add 100ml of graphene oxide dispersion to 100ml of polyethyleneimine ...

Embodiment 2

[0053] The self-assembled graphene composite material of this embodiment is prepared by the following method:

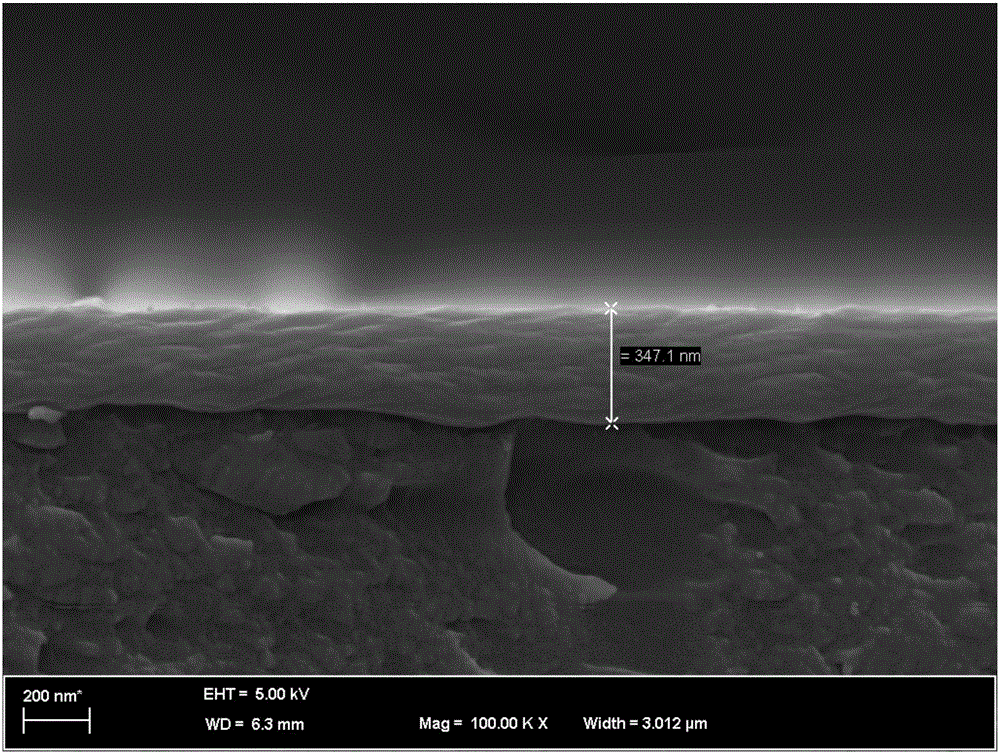

[0054] The graphene composite material with one layer of barrier coating obtained in Example 1 was repeatedly immersed in the PSS-RGO dispersion (concentration of 0.5mg / ml, pH=3), deionized water, and PEI-RGO dispersion (concentration of 0.5mg / ml, pH=9), the operation in deionized water, the immersion time is 10 minutes each time, and the operation is repeated 9 times to obtain a graphene composite material with 10 barrier coatings.

[0055] The obtained graphene composite material with 10-layer barrier coating is recorded as (PSS-RGO / PEI-RGO) 10 .

Embodiment 3

[0057] The self-assembled graphene composite material of this embodiment is prepared by the following method:

[0058] The graphene composite material with one layer of barrier coating obtained in Example 1 was repeatedly immersed in the PSS-RGO dispersion (concentration of 0.5mg / ml, pH=3), deionized water, and PEI-RGO dispersion (concentration of 0.5mg / ml, pH=9), the operation in deionized water, the immersion time is 10 minutes each time, and the operation is repeated 19 times to obtain a graphene composite material with 20 layers of barrier coatings.

[0059] The obtained graphene composite material with 20 layers of barrier coating is recorded as (PSS-RGO / PEI-RGO) 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com