Preparation method of nanometer silver/antimony doped tin oxide composite transparent conductive heat reflection coating

A technology of antimony-doped tin oxide and heat-reflective coating, which is applied in the coating and other directions, can solve the problems of doping concentration limitation, difficulty in controlling the doping concentration of antimony ions, and inability to achieve uniform mixing and effective doping of nano-silver, etc., to achieve Ensures stability and prevents coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

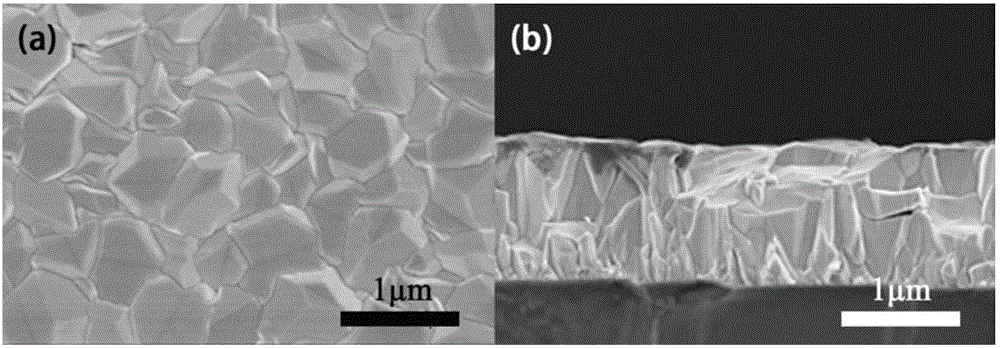

[0017] The film layer structure is glass substrate / Ag+ATO (ATO, Antimony-doped Tin Oxide, that is, antimony-doped tin oxide), and the preparation method is as follows:

[0018] (1) Prepare nano-silver sol: take silver nitrate as raw material, take ethylene glycol as reducing agent and solvent, take polyvinylpyrrolidone with molecular weight as 40000 as stabilizer, silver nitrate concentration is 0.05mol / L, stabilizer and silver nitrate The molar ratio is 4:1, and the nano-silver sol is obtained by the reaction, the reaction temperature is 120° C., and the reaction time is 1 h.

[0019] (2) Preparation of ATO sol: respectively with SbCl 3 , SnCl 2 As a raw material, use ethylene glycol as a solvent and a coordination stabilizer, add the same volume of glacial acetic acid to inhibit the hydrolysis of metal salts, and stir and react at 70°C for 2h (after testing, the temperature is 60-100°C and the time is 2-4h , have no significant impact on the invention effect), the preparat...

Embodiment 2

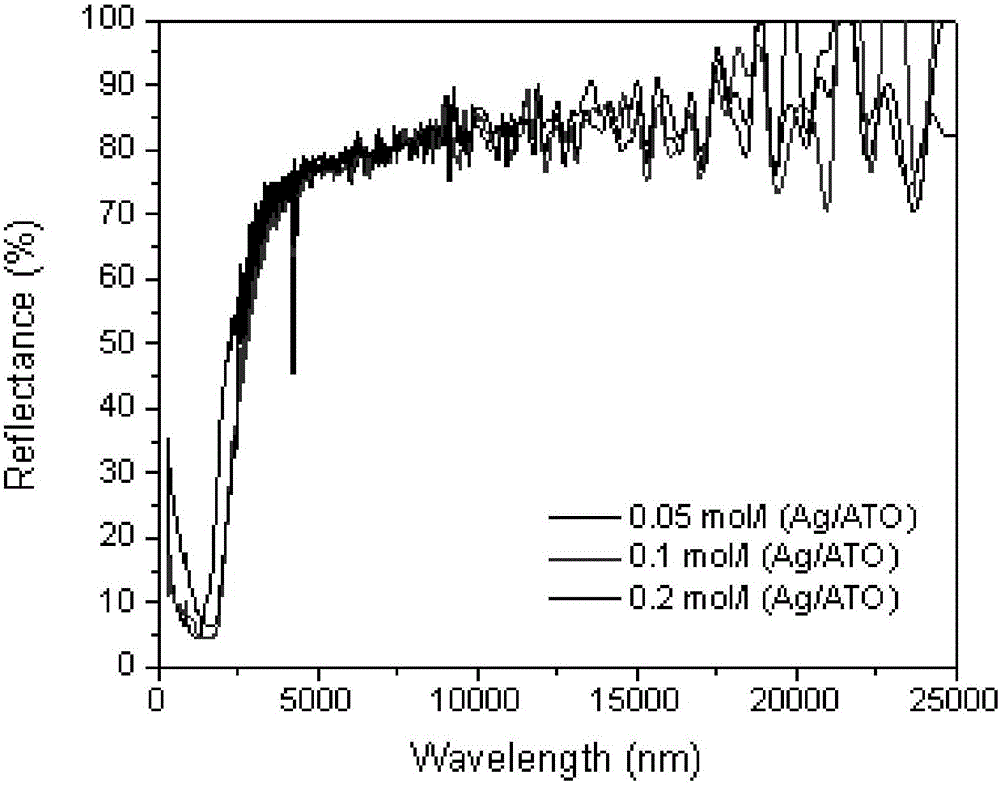

[0024] Referring to Example 1, the difference is that the molecular weight of the polyvinylpyrrolidone used when preparing the nano-silver sol is 20,000. The surface resistance of the prepared coating reaches 20Ω / □, the infrared starting point is at 2.5 microns, and the infrared heat reflectivity reaches 80%.

Embodiment 3

[0026] Referring to Example 1, the difference is that the molecular weight of the polyvinylpyrrolidone used when preparing the nano-silver sol is 60,000. The surface resistance of the prepared coating reaches 20Ω / □, the infrared starting point is at 2.5 microns, and the infrared heat reflectivity reaches 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com