Supercritical extraction technology of cynomorium songaricum oil

A supercritical and Cynomorium technology, applied in the field of biochemistry, can solve problems such as difficulty in extraction, loss of antioxidant activity, and low oil content, and achieve the effects of no solvent residue, short extraction cycle, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Cynomorium supercritical CO 2 The main steps of extraction are as follows:

[0024] In the first step, the collected cynomorium stems from which inflorescences have been removed are removed from impurities and crushed to obtain cynomorium powder.

[0025] In the second step, the Cynomorium powder is dried at 30°C to 40°C, and sieved through a sieve with a pore size of 0.177 μm to 0.25 μm.

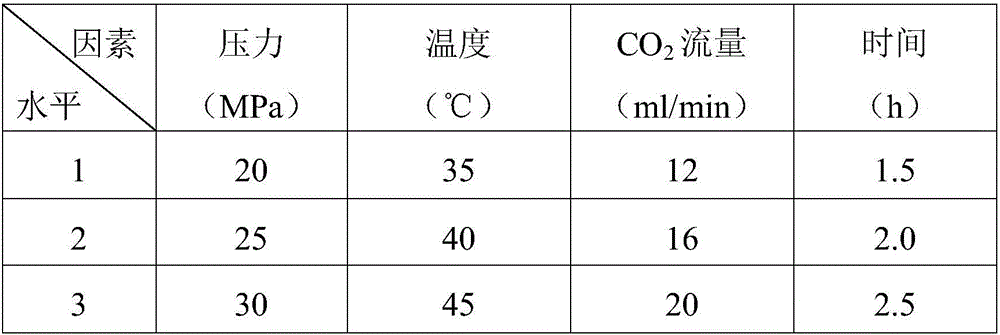

[0026] In the third step, using supercritical CO 2 The fluid extracts the sieved Cynomorium powder, the fluid extraction pressure is 20-30MPa, the extraction temperature is 35°C-45°C, CO 2 The fluid flow rate is 12ml / min-20ml / min, the extraction time is 1.5h-2.5h, and the Cynomorium oil extract is obtained.

[0027] The fourth step is to centrifuge the Cynomorium oil extract in a high-speed centrifuge with a rotation speed of 10000r / min-12000r / min at a room temperature of 20-30°C for 10min-30min to remove impurities and obtain Cynomorium oil.

[0028] Wherein, in the second step,...

Embodiment 2

[0033] Cynomorium supercritical CO 2 The main steps of extraction are as follows:

[0034] In the first step, the collected cynomorium stems from which inflorescences have been removed are removed from impurities and crushed to obtain cynomorium powder.

[0035] In the second step, the Cynomorium powder is dried at 30° C. for 24 hours, and sieved with a sieve with a pore size of 0.177 μm.

[0036] In the third step, using supercritical CO 2 The fluid extracts the sieved Cynomorium powder, the fluid extraction pressure is 30MPa, the extraction temperature is 40°C, CO 2 The fluid flow rate is 12ml / min, the extraction time is 2.5h, and the Cynomorium oil extract is obtained.

[0037] The fourth step is to place the Cynomorium oil extract in a high-speed centrifuge with a rotation speed of 12000r / min at room temperature for 10 minutes to remove impurities and obtain Cynomorium oil. Cynomorium oil extraction rate reached 2.78%.

Embodiment 3

[0039] In the first step, the collected cynomorium stems from which inflorescences have been removed are removed from impurities and crushed to obtain cynomorium powder.

[0040] In the second step, the Cynomorium powder is dried at 40°C and sieved through a sieve with a pore size of 0.25 μm.

[0041] In the third step, using supercritical CO 2 The fluid extracts the sieved Cynomorium powder, the fluid extraction pressure is 30MPa, the extraction temperature is 45°C, CO 2 The fluid flow rate is 12ml / min, the extraction time is 2.5h, and the Cynomorium oil extract is obtained.

[0042] In the fourth step, the Cynomorium oil extract is placed in a high-speed centrifuge with a rotation speed of 12000r / min and centrifuged for 10 minutes at a room temperature of 25°C to remove impurities and obtain Cynomorium oil. Cynomorium oil extraction rate reached 2.64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com