Processing method of corrosion-resistant aluminum plate

A processing method and corrosion-resistant technology, which can be used in metal-free paints, devices for applying liquid to surfaces, coatings, etc., which can solve the problems of weak corrosion resistance, low strength and hardness of aluminum plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

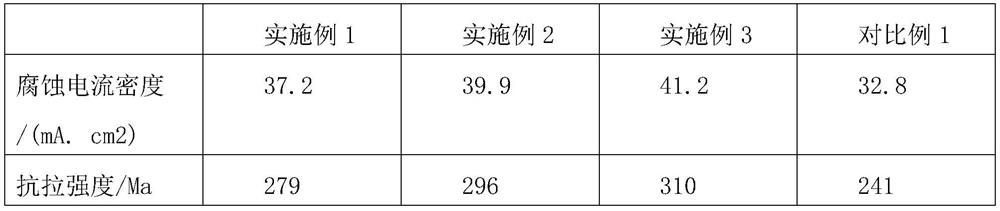

Examples

Embodiment 1

[0020] A kind of processing method of corrosion-resistant aluminum plate that the present invention proposes, comprises the following steps:

[0021] 1) Put 10 parts of magnesium, 10 parts of chromium, 5 parts of titanium and 70 parts of aluminum into the furnace for calcination at a temperature of 700-850°C. After 15 minutes, cool to 350°C at a cooling rate of 10°C / s, and then Add 9 parts of carbon into the furnace, and after 50 minutes, a metal mixture is obtained;

[0022] 2) casting the metal mixture to obtain an aluminum ingot, and making the aluminum ingot into a preliminary aluminum plate through a rolling process;

[0023] 3) Place the primary aluminum plate in the degreasing tank, pour the degreasing agent into the degreasing tank to carry out the degreasing process on the primary aluminum plate, the solid-liquid mass volume ratio of the primary aluminum plate and the degreasing agent is 3:1 for the degreasing agent, The degreasing agent is a mixed solution of 3 part...

Embodiment 2

[0027] A method for processing a corrosion-resistant aluminum plate, comprising the following steps:

[0028] 1) Put 15 parts of magnesium, 15 parts of chromium, 8 parts of titanium and 90 parts of aluminum into the furnace for calcination at a temperature of 850°C. After 15-25 minutes, cool to 500°C at a cooling rate of 10°C / s, and then Add 15 parts of carbon into the furnace, and after 80 minutes, a metal mixture is obtained;

[0029] 2) casting the metal mixture to obtain an aluminum ingot, and making the aluminum ingot into a preliminary aluminum plate through a rolling process;

[0030] 3) Place the primary aluminum plate in the degreasing tank, pour the degreasing agent into the degreasing tank to carry out the degreasing process on the primary aluminum plate, the solid-liquid mass volume ratio of the primary aluminum plate and the degreasing agent is 3:1 for the degreasing agent, The degreasing agent is a mixed solution of 5 parts of sodium nitrate, 8 parts of citric a...

Embodiment 3

[0034] A method for processing a corrosion-resistant aluminum plate, comprising the following steps:

[0035] 1) Put 12 parts of magnesium, 12 parts of chromium, 6 parts of titanium and 80 parts of aluminum into the furnace for calcination. Add 9-15 parts of carbon, and after 70 minutes, a mixed metal solution is obtained;

[0036] 2) casting the metal mixture to obtain an aluminum ingot, and making the aluminum ingot into a preliminary aluminum plate through a rolling process;

[0037] 3) Place the primary aluminum plate in the degreasing tank, pour the degreasing agent into the degreasing tank to carry out the degreasing process on the primary aluminum plate, the solid-liquid mass volume ratio of the primary aluminum plate and the degreasing agent is 3:1 for the degreasing agent, The degreasing agent is a mixed solution of 4 parts of sodium nitrate, 7 parts of citric acid and 6 parts of tea saponin. for polishing;

[0038] 4) Rinse the polished aluminum plate with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com